How To Detect Part Depth Through Visual Inspection

In industrial manufacturing, precise part depth detection is essential for quality control. Traditional manual measurement methods, like using calipers, are slow and error - prone. Human factors such as fatigue and inconsistent force application lead to inaccuracies, and parallax errors or improper calibration can further degrade precision. These issues become critical in mass production, causing costly rework and delivery delays.

Visual inspection, powered by advanced imaging, offers a superior alternative. It enables non - contact, high - speed measurement of parts, safeguarding delicate components and maintaining production line efficiency. Capable of handling complex geometries, visual inspection has become a cornerstone of modern manufacturing quality assurance.

1. Introduction to Visual Inspection for Depth Detection

Visual inspection for part depth detection captures part images and processes them to extract depth - related data. Unlike manual measurement, it offers non - contact operation, eliminating the risk of damaging delicate parts during the measurement process. In the production of micro - electronic components, where parts are often extremely small and fragile, even the slightest touch from a measuring tool can cause deformation or breakage, but visual inspection ensures the integrity of these sensitive parts.

Moreover, visual inspection enables high - speed processing, capable of analyzing multiple parts in a matter of seconds, which is essential for maintaining the pace of modern mass production lines. With automated visual inspection systems, parts can be inspected continuously without the need for frequent operator intervention, greatly enhancing production efficiency. Additionally, it can handle parts with complex geometries that are difficult, if not impossible, to measure accurately by hand. Irregularly shaped parts, such as the intricate molds used in the plastics industry, can be precisely measured for depth using visual inspection techniques, providing detailed data that manual methods simply cannot achieve. These advantages make visual inspection widely applicable across various industries.

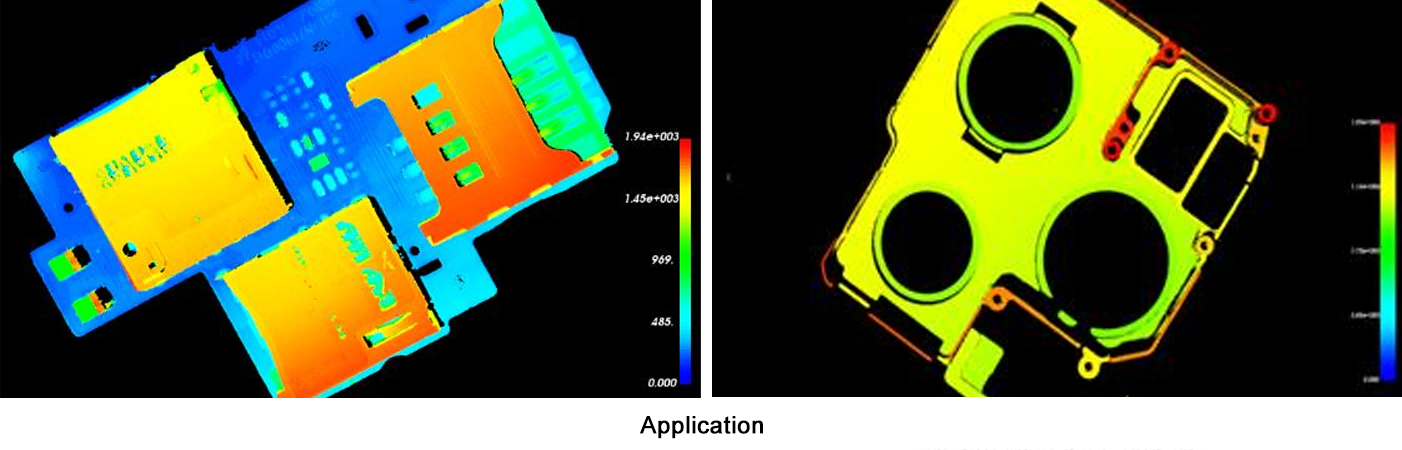

2. Common 3D Visual Inspection Techniques for Depth Detection

2.1 Stereo Vision

Stereo vision uses two or more cameras to capture images from different viewpoints. By calculating the disparity between these images and applying the triangulation principle, it determines the depth of points on the part's surface. This technique is particularly suitable for complex - shaped parts, providing relatively high - accuracy depth information.

Case in Point: Aerospace industry uses stereo vision to measure the depth of turbine blades' complex surfaces, ensuring aerodynamic performance and flight safety.

2.2 Structured Light

Structured light projects patterns like stripes or grids onto the part. When the pattern deforms due to surface depth variations, a camera captures the change. Analyzing the distortion, especially the phase shift of stripes, allows for calculating the part's depth. It offers high - resolution measurements and fast data acquisition, making it ideal for small, detailed parts.

Example Application: In micro - chip production, structured light measures the depth of trenches and bumps on chips, ensuring proper electrical performance.

2.3 Time - of - Flight (ToF)

ToF cameras measure the time light takes to travel to the part and back. Using the known speed of light, the depth is calculated. They can quickly generate a depth map, which is extremely useful for real - time applications, although accuracy can be affected by ambient light and object reflectivity.

Practical Scenario: In robotic package sorting, ToF cameras on robotic arms measure package surface depth in real - time for accurate grasping.

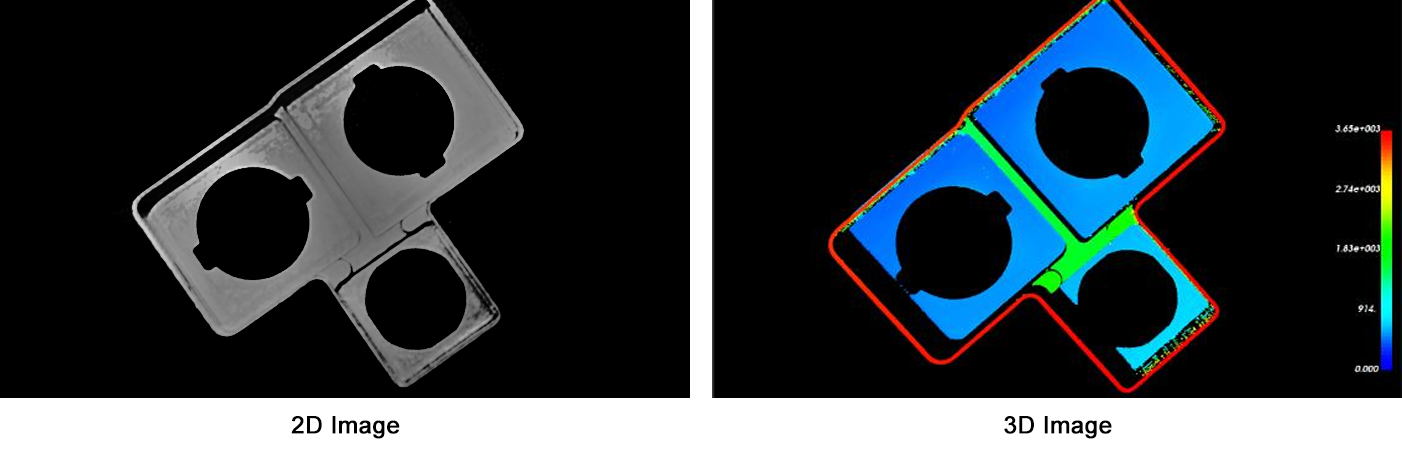

3. Comparison between Regular Cameras and 3D Cameras for Depth Detection

Regular cameras mainly capture 2D images. For depth detection, they rely on additional techniques like stereo matching or structure from motion, which are complex and time - consuming. These methods require significant computational resources and often involve processing large amounts of data, making them less suitable for real - time applications. 3D cameras, designed specifically for depth detection, directly generate depth maps. They provide accurate depth measurement and can handle various surfaces well, making them suitable for a wide range of industrial applications. However, 3D cameras are more costly, with prices ranging from several thousand to tens of thousands of dollars, including the necessary hardware and data - processing software. This higher cost is a significant factor that businesses need to consider when deciding whether to invest in 3D camera - based inspection systems.

4. Challenges and Solutions in Visual Inspection for Depth Detection

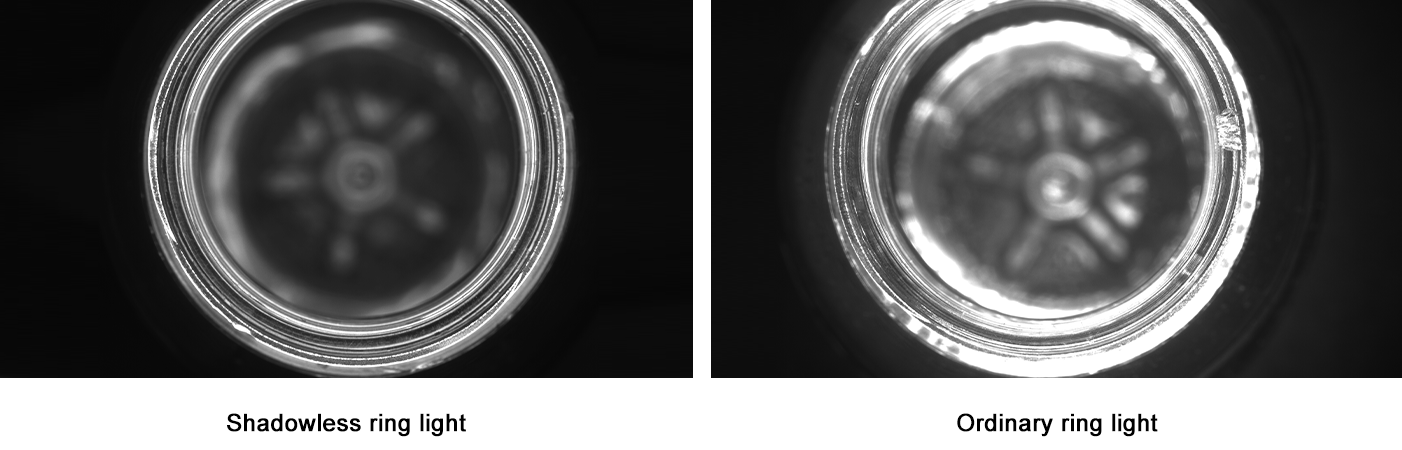

A major challenge is dealing with lighting variations, which can distort images and depth measurements. In industrial environments, lighting conditions can change due to factors such as the time of day, the use of different light sources, or the movement of objects that cast shadows. Adaptive lighting systems that adjust light source parameters, including intensity, color temperature, and direction, according to the inspection environment can solve this problem. These systems use sensors to detect changes in lighting and automatically optimize the illumination to ensure consistent and accurate image capture.

Complex part surfaces, such as transparent or reflective ones, also pose difficulties. Transparent parts, like optical lenses, allow light to pass through, making it hard to determine the exact surface depth. For such parts, techniques such as using polarized light or multi - wavelength imaging can be employed. Polarized light reduces glare and reflections, while multi - wavelength imaging can penetrate the material to some extent and provide information about the internal and surface structures. For reflective surfaces, anti - reflective coatings or special lighting arrangements, like using diffuse lighting, can be considered to ensure accurate depth detection.

5. Future Trends

The future of depth detection in visual inspection lies in the integration of artificial intelligence and machine learning. Deep - learning algorithms, like convolutional neural networks (CNNs), will enhance detection accuracy. These algorithms can learn complex patterns from large amounts of data and automatically extract depth information with high precision, even in challenging scenarios with complex backgrounds or parts with irregular shapes.

Combining different visual inspection techniques, such as stereo vision and ToF, will provide more comprehensive depth information. This hybrid approach can leverage the strengths of each technique, overcoming their individual limitations and offering more accurate and reliable depth measurement.

In conclusion, visual inspection provides a reliable way to detect part depth. By understanding different techniques, their comparisons, and addressing challenges, manufacturers can optimize their quality control processes. As technology advances, visual inspection will play an even more significant role in industrial manufacturing, driving innovation and improving overall production efficiency.