Cost-Effective Machine Vision Lighting for Small-Scale Manufacturing

Understanding Machine Vision Lighting Fundamentals

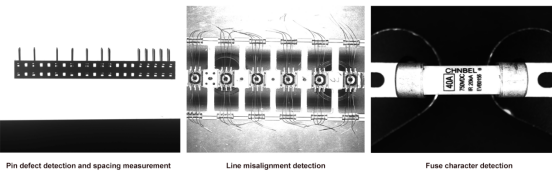

Role of Lighting in Small-Scale Automation

Lighting plays an essential role in the functionality of machine vision systems, significantly affecting image quality and overall system accuracy. In small-scale automation, the importance of precise lighting becomes even more pronounced, as it enhances contrast and emphasizes features that are critical for tasks like inspection and sorting. Effective lighting setups can influence operational outcomes dramatically. For instance, statistical data shows that operations employing optimized lighting witness up to a 30% improvement in inspection accuracy. With technologies such as ring lights or dome lights, better illumination can be achieved, enabling clearer visibility of objects, thus enhancing performance and reliability in small-scale automated systems.

Key Challenges in Small-Batch Production

Small-batch production often competes with significant challenges, notably inconsistent lighting conditions, which can undermine uniformity in results. Manufacturers face the dilemma of investing in expensive lighting setups for minimal production volumes. According to a recent survey, nearly 40% of manufacturers highlighted inadequate lighting as a prime obstacle to efficient small-batch operations. Balancing the cost of high-quality lighting solutions with the demands of precision in production remains a constant struggle. The use of various lighting technologies like bar lights or SWIR cameras can provide tailored solutions to improve consistency without incurring excessive costs, thus enhancing production efficiency and ensuring quality end products.

Types of Cost-Effective Machine Vision Lighting

Ring Lights for Precision Component Inspection

Ring lights are a vital component for achieving precision in component inspection due to their ability to provide uniform illumination and eliminate shadows. This type of lighting is especially beneficial in tasks requiring high accuracy, such as examining small, detailed parts. The ease of mounting ring lights directly onto cameras enhances the effectiveness of compact setups, making them a preferred choice in space-limited environments. Several case studies highlight that using ring lights can improve feature recognition by up to 25% during component inspections. This improvement underscores the role of ring lights in enhancing precision within automated systems.

Bar Lights for Conveyor-Based Applications

Bar lights are specifically designed to offer broad illumination across conveyor lines, thus improving the visibility crucial for uninterrupted production processes. The flexibility to adjust their angle and intensity makes them particularly useful when handling varying product sizes and materials. As conveyor systems are central to many manufacturing facilities, efficient lighting from bar lights can significantly enhance production efficiency. Industry reports have shown that implementing bar lights can lead to an estimated 15% increase in throughput efficiency. This boost reflects the importance of tailored lighting solutions in maintaining operational flow on conveyor lines.

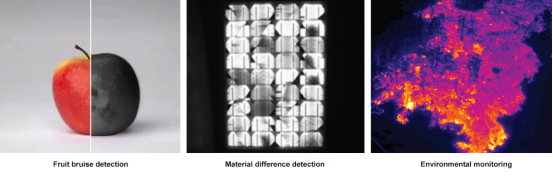

Dome Lights for Surface Defect Detection

Dome lights are ideal for surface defect detection due to their ability to diffuse light evenly across surfaces, thereby illuminating flaws with comprehensive coverage. These lights minimize unwanted reflections, ensuring that the attention remains on surface anomalies rather than environmental distractions. Research supports that the implementation of dome lights in defect detection processes can reduce missed defects by approximately 20%. This statistic highlights the critical role that dome lights play in quality control by ensuring even the smallest defects are detected, thus striving for higher standards of quality in production outputs.

Optimizing Lighting ROI for Limited Budgets

Balancing Initial Costs vs. Long-Term Savings

Investing in quality lighting systems might seem costly at first, but it often leads to significant long-term savings and improved efficiency. By analyzing lifecycle cost models, businesses can find that the initial expense of efficient lighting solutions can be offset, recovering entirely within 2-3 years through energy savings. Additionally, economic assessments have repeatedly demonstrated that a well-planned lighting setup can enhance return on investment (ROI) by up to 20%. When deciding on lighting solutions, it's crucial to weigh the upfront expenses against potential long-term benefits, including reduced maintenance and operational costs.

Energy-Efficient LED Solutions

One of the most impactful advancements in lighting technology is the rise of LED solutions, which have dramatically reduced energy consumption. These systems are ideal for operations mindful of budgeting as they offer prolonged lifespans compared to traditional lighting, resulting in fewer replacements and associated costs. For instance, statistics forecast potential energy savings of up to 75% for businesses switching to LED lighting solutions. By prioritizing energy-efficient lighting like LEDs, businesses can not only cut energy costs but also contribute to sustainability goals through reduced energy usage and waste.

Maintenance Strategies for Small Operations

Regular maintenance schedules are vital for extending the lifespan and performance of lighting systems, especially in small operations where resources might be limited. Implementing proactive maintenance can significantly diminish the chance of failures during crucial production periods. Maintenance audits reveal that scheduled checks can enhance lighting reliability by up to 30%. By establishing routine maintenance strategies, small operations can ensure consistent lighting performance, optimizing production capabilities and preventing unexpected interruptions that might affect operational efficiency.

Integration Techniques for Small Facilities

Matching Lighting to High-Speed Cameras

Optimizing lighting conditions is crucial when using high-speed cameras, as it significantly enhances the sharpness of images captured in rapid motion. Proper synchronization between lighting and camera settings is essential, as it greatly improves the accuracy and quality of image capture. Technical guides highlight that aligning optimal lighting conditions with high-speed cameras can enhance motion analysis quality by as much as 40%. For small facilities, this precision is important as it ensures that rapid processes are accurately documented, leading to improved quality control and product consistency.

SWIR Camera Compatibility Considerations

Integrating lighting with short-wave infrared (SWIR) cameras requires careful consideration due to their unique sensitivity range. The use of suitable lighting types is crucial for enhancing the spectral range that these advanced systems can capture. Research suggests that adopting proper SWIR-compatible lighting can increase detection rates by up to 30% in specialized applications. This is critical in fields where subtle differences need to be detected such as semiconductor inspection or moisture observation. Knowing the spectral requirements of a SWIR camera and selecting auxiliary lighting accordingly can significantly enhance the detection capabilities of even small-scale facility operations.

Matching Lighting to High-Speed Cameras

Successfully integrating the right lighting solution with high-speed cameras is critical for capturing sharp images of fast-moving objects. To be effective, there must be precise synchronization between the lighting setup and the camera settings. This has a significant impact on the accuracy of image capture, especially in fast-paced environments like assembly lines or motion analysis applications. According to technical handbooks, using optimized lighting setups can enhance the quality of motion analysis output by up to 40%. This is crucial for small facilities where achieving precise imaging is necessary for quality control and accurate assessments. Prioritizing lighting integration helps ensure that high-speed cameras can capture detailed and precise images, ultimately leading to more reliable data and improved decision-making capabilities. Effective integration of lighting with high-speed cameras not only reduces errors but also plays a significant role in improving the overall productivity of small operations.

SWIR Camera Compatibility Considerations

When working with SWIR (Short Wave Infrared) cameras, it's essential to choose lighting that complements their unique sensitivity range to ensure efficiency. SWIR cameras capture images using specific wavelengths between the visible and mid-infrared spectra, which makes them ideal for specialized applications such as detecting moisture, identifying material differences, and analyzing heat signatures. By selecting the appropriate light sources, businesses can enhance the spectral range captured by these cameras, leading to a measurable increase in the accuracy of detection rates, with studies indicating improvements by as much as 30% in certain applications. Therefore, matching the right lighting conditions to the operational requirements of SWIR cameras is crucial for small facilities aiming to optimize limited budgets and resources. Implementing SWIR-compatible lighting solutions ensures effective operations and can even result in improved detection accuracy by 30%, as supported by recent studies.

Space-Constrained Installation Best Practices

For small facilities, optimally designing lighting installations to address space constraints while maximizing coverage is vital. Utilizing compact lighting solutions, such as bar lights, can be an effective method to maximize space efficiency. By strategically placing these compact solutions, small spaces can achieve significant illumination without unnecessary shadowing. Industry best practices indicate that when lights are strategically placed, unwanted shadows in 90% of installations are minimized. This ultimately allows even limited space facilities to benefit from well-distributed lighting, improving operational efficiency and achieving the desired lighting outcome, even in confined spaces.

Future-Proofing Your Lighting Setup

Emerging Trends in Compact Illumination

In recent years, there has been a noticeable shift toward more compact and powerful lighting solutions, particularly for use in limited spaces. The industry is leaning towards innovations that focus on adaptive technologies, allowing lights to adjust their intensity and direction based on real-time data inputs. This trend not only optimizes space usage but also enhances operational efficiency by providing precise lighting adjustments as required. Market forecasts indicate a growing demand for these compact illumination solutions, especially in automation settings where space optimization and adaptability are critical.

Scalable Systems for Growing Operations

For facilities planning to expand their operations, the implementation of scalable lighting systems is crucial. These systems are designed to be flexible, enabling easy upgrades and expansions without the need for complete overhauls—this is vital for optimizing budget allocations. Facilities can begin with a basic setup and progressively incorporate additional components as the need arises, ensuring alignment with operational growth. Many businesses have successfully employed modular lighting systems, which offer the capacity to efficiently scale according to changing demands without disrupting ongoing operations.