How to Select Industrial Camera Interfaces in Machine Vision?

How much do you know about industrial camera interfaces? Common industrial camera interfaces can be divided into various types, including Gigabit Ethernet (GigE), 10-Gigabit Ethernet (10-GigE), USB3.0, USB2.0, CameraLink, and CoaXPress. What are the differences between them, and how should we make selections?

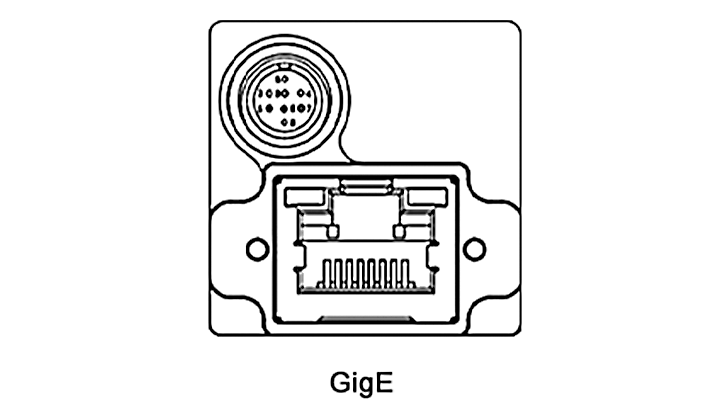

The most widely used interface is Gigabit Ethernet (GigE), favored for its affordability and universal availability. It suitable for medium-resolution and high-frame-rate applications, could support transmission distances up to 100 meters without repeaters (extendable with signal boosters) and delivers speeds up to 1 Gbps. With strong anti-interference capabilities, it meets most industrial application requirements.

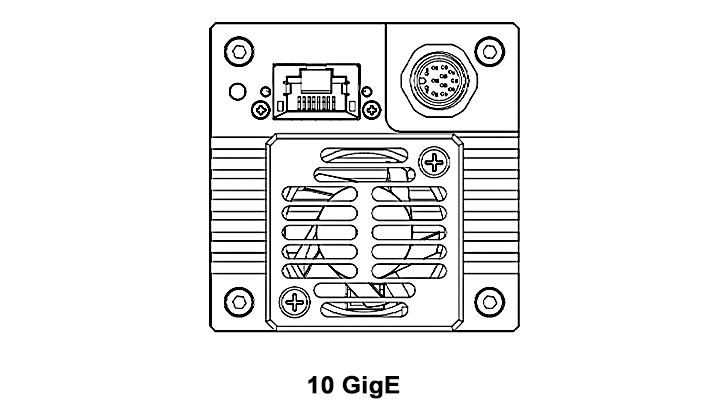

Its upgraded version, 10-Gigabit Ethernet (10-GigE), offers tenfold speed improvements (10 Gbps) while maintaining similar characteristics to GigE. It can reach 30 meters over standard copper cables; fiber optics extend to 10+ kilometers (with converters). This interface is ideal for users prioritizing high-speed transmission while remaining cost-conscious. It can used in high-speed motion analysis, 4K/8K imaging, and large-scale multi-camera synchronization systems demanding extreme bandwidth.

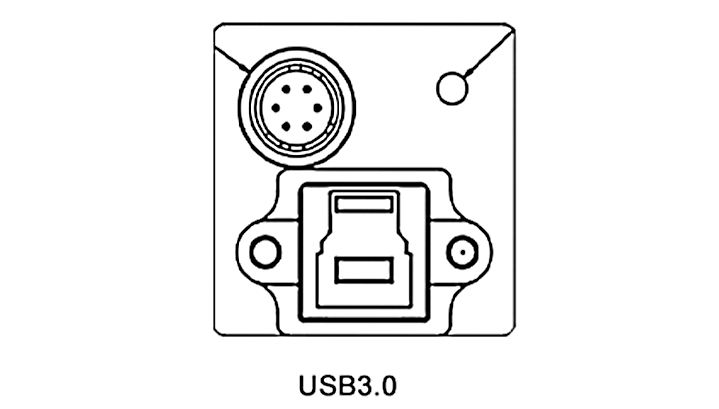

USB3.0 interfaces achieve speeds of 3 Gbps but suffer from inherent USB limitations: weak anti-interference performance and a recommended maximum cable length of 5 meters (beyond which packet loss and frame drops become frequent). Its anti-interference capability is moderate, improved signal protocols but limited cable shielding. Despite these drawbacks, their ubiquity ensures widespread industrial adoption. It is suitable for Medium-speed industrial inspection, medical imaging, laboratory research, and scenarios requiring flexible deployment.

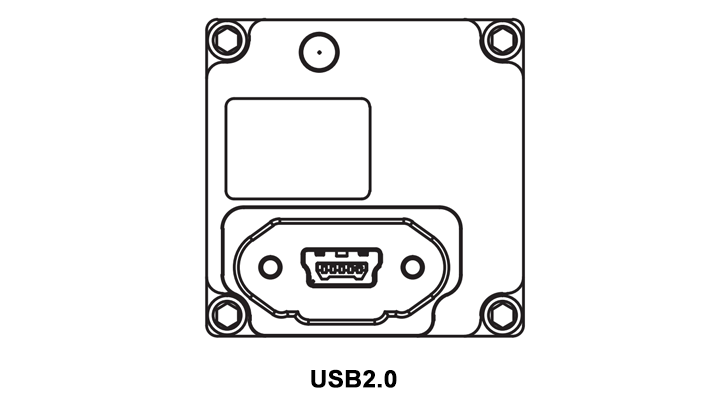

USB2.0 offers a maximum theoretical speed of 480 Mbps (megabits per second), which is significantly slower than modern interfaces like USB3.0 or GigE. This makes it suitable only for low-resolution or low-frame-rate imaging applications. Its effective cable length is limited to approximately 3–5 meters without signal degradation. Due to its low cost and plug-and-play convenience, USB2.0 remains relevant in non-critical, budget-conscious applications such as basic inspection systems, educational setups, or legacy equipment where speed demands are minimal.

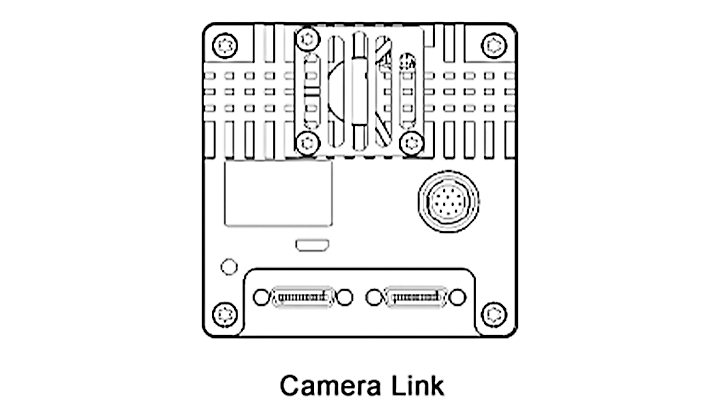

CameraLink supports high-speed data transfer, with configurations ranging from Base (2.04 Gbps) to Deca (6.8 Gbps). While faster than GigE or USB, it is now outperformed by CoaXPress (CXP). Using dedicated frame grabbers and coaxial cables, CameraLink can achieve stable transmission up to 10 meters. However, longer distances require repeaters or fiber-optic converters, increasing complexity and cost. Designed for industrial use, CameraLink provides robust EMI resistance through shielded cables and differential signaling, making it reliable in harsh environments. Once the gold standard for high-speed imaging, CameraLink is still used in legacy systems or applications requiring moderate speeds with deterministic latency, such as semiconductor inspection, high-speed conveyor systems, or scenarios where upgrading to CXP is cost-prohibitive.

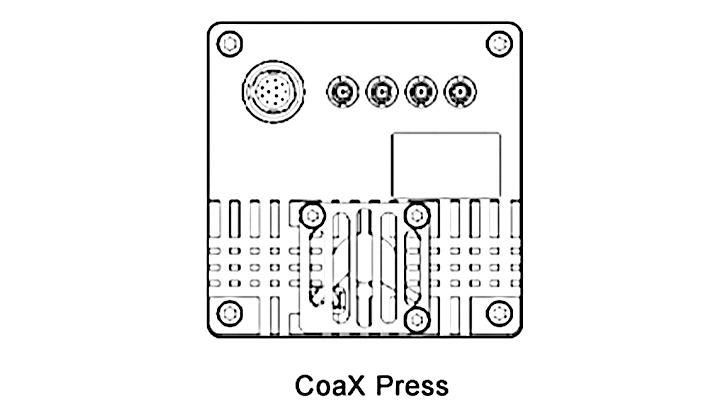

Finally, the increasingly popular CoaXPress (CXP) interface stands out for ultra-high-speed applications. Capable of exceeding 50 Gbps, it has become essential for ultra-high-resolution scenarios involving tens or hundreds of megapixels. Its emergence has made previously dominant high-speed interfaces like CameraLink pale in comparison. When budget constraints are minimal and extreme speed is paramount, CXP emerges as the optimal choice.

So how to choose the interfaces of industrial cameras in machine vision system? It depends on balancing speed, distance, environmental demands, and budget. Like budget-conscious generally uses Gige interface or USB3.0 interface. High speed or high resolution application could use 10-Gige interface or CXP interface. Legacy or low-latency systems could use CameraLink interface. Low-cost and non-critical tasks could use USB 2.0 interface.