Versatile Machine Vision Lenses: Adapting to Diverse Manufacturing Inspection Requirements

Versatile Machine Vision Lenses: Adapting to Diverse Manufacturing Inspection Requirements

Modern manufacturing demands unprecedented flexibility. As production lines handle smaller batches, faster changeovers, and increasingly complex materials, versatile machine vision lenses become critical enablers of quality and efficiency. HIFLY understands these evolving challenges, designing optics that dynamically adapt to your inspection needs without compromising precision.

The High-Mix Production Challenge

Frequent product changeovers plague manufacturers running high-variability lines. Traditional lenses often require manual recalibration or complete swaps when inspecting different components—a single automotive line might examine engine castings, reflective connectors, and textured rubber seals within hours. Versatile machine vision lenses with motorized zoom capabilities and quick-mount interfaces could reduce reconfiguration time by up to 85%. Engineers may leverage adjustable working distance lenses to maintain focus across varying part dimensions, eliminating downtime during transitions.

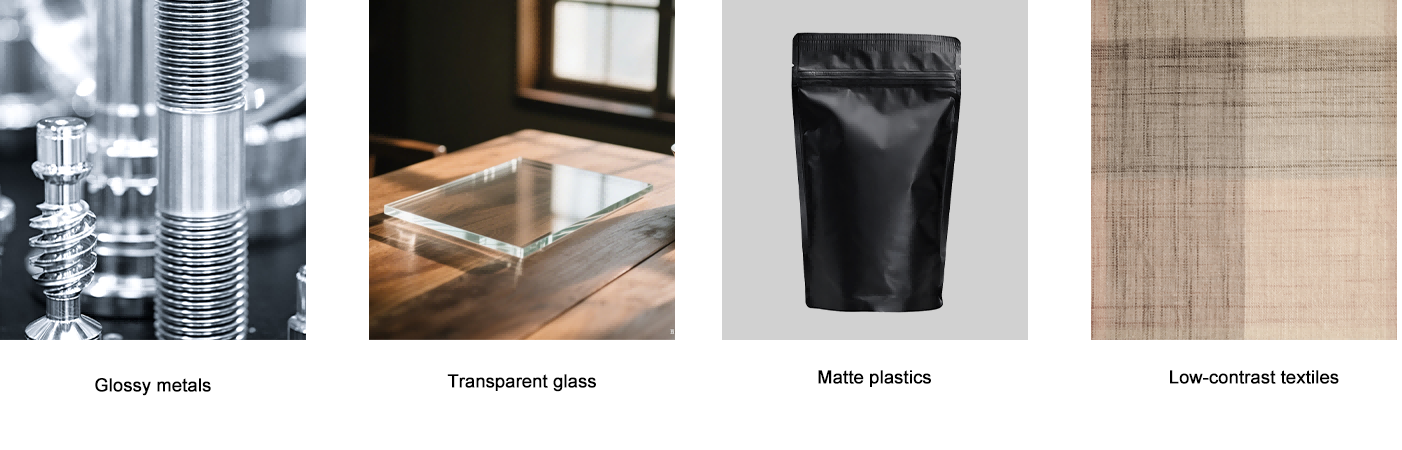

Conquering Material Complexity

Inspecting diverse surfaces—glossy metals, transparent glass, matte plastics, or low-contrast textiles—creates inconsistent imaging results. Standard lenses struggle with glare on polished surfaces or fail to capture defects on dark materials. Telecentric optics could eliminate perspective errors for metrology-critical tasks, while multi-spectral coatings might enhance contrast on challenging substrates. For food/pharma applications where glass bottles and labels coexist in one inspection point, versatile machine vision lenses with extended depth-of-field capabilities maintain sharpness across uneven planes without requiring additional cameras.

Precision at Scale

Micro-electronics manufacturers face dual demands: scrutinizing sub-millimeter solder joints while verifying larger PCB assemblies. Fixed-focal lenses force compromises. HIFLY’s approach integrates macro-to-mid-range magnification in single optical groups, enabling seamless transitions between 0201 component inspection and full-board alignment checks. Such versatile machine vision lenses support resolutions down to 1.5μm while maintaining edge-to-edge clarity—critical for semiconductor pad measurements or medical device verifications where micron-level deviations trigger failures.

Surviving Industrial Extremes

Dust, vibrations, temperature swings, and washdown conditions degrade optical performance. Non-sealed lenses develop internal condensation; plastic housings warp under thermal stress. Ruggedized versatile machine vision lenses with IP67-rated metal bodies and temperature-stabilized glass could operate reliably in foundries or frozen food plants. Anti-vibration mounts further ensure consistent focus during high-speed conveyor operations, where even 0.1mm shift might blur critical defect images.

Future-Proofing Vision Systems

As product lifecycles shorten, manufacturers avoid lenses requiring full system overhauls for new applications. Modular designs allowing front-end optical component swaps (e.g., switching from wide-angle to telecentric modules) extend hardware relevance. HIFLY’s versatile machine vision lenses incorporate standardized interfaces compatible with C/CS-mounts and diverse sensors, simplifying integration with existing automation controllers. Combined with software-driven aperture/focus controls, this adaptability transforms lenses from static components into scalable vision platforms.

Strategic Advantages of Optical Versatility

Investing in adaptive optics delivers measurable operational benefits:

- Cost Control: Reduced need for duplicate camera setups

- Agility: Faster validation for new product inspections

- Quality Assurance: Consistent accuracy across materials/sizes

- Uptime Protection: Sealed designs minimize maintenance interruptions

For automotive suppliers inspecting both matte brake pads and chrome-plated fittings on the same line, or electronics assemblers verifying microscopic connectors alongside large heat sinks, versatile machine vision lenses might be the most strategic upgrade this quarter.