Next-Gen Flat Dome Lighting: Revolutionizing Machine Vision Inspection

Introduction: Shining a Light on Precision Inspection

In the world of machine vision, lighting is everything. Whether you’re identifying tiny characters on packaging, inspecting curved metal surfaces, or ensuring flawless glass products, the right lighting solution can make or break your results. Enter the second-generation flat dome light—a game-changer that combines cutting-edge technology with sleek design to deliver unparalleled clarity and precision. This blog post explores how this innovative lighting solution enhances defect detection and character recognition, its standout features, and why it’s a must-have for industries aiming for perfection.

Why Second-Generation Flat Dome Lighting Matters

Traditional lighting systems often struggle with challenges like uneven illumination, glare, or unwanted patterns (like moiré ripples) that obscure critical details. The second-generation flat dome light addresses these issues head-on, offering a versatile solution for inspecting complex surfaces—think packaging, metal, curved, concave, or glass materials. By providing consistent, high-quality illumination, it ensures machine vision systems can detect defects and read characters with pinpoint accuracy, boosting efficiency and reducing errors.

Key Features of the Second-Generation Flat Dome Light

This advanced lighting solution is packed with features designed to elevate machine vision performance:

Special Light-Guiding Material: Printed with ultra-fine, equidistant dotted patterns to ensure uniform light distribution.

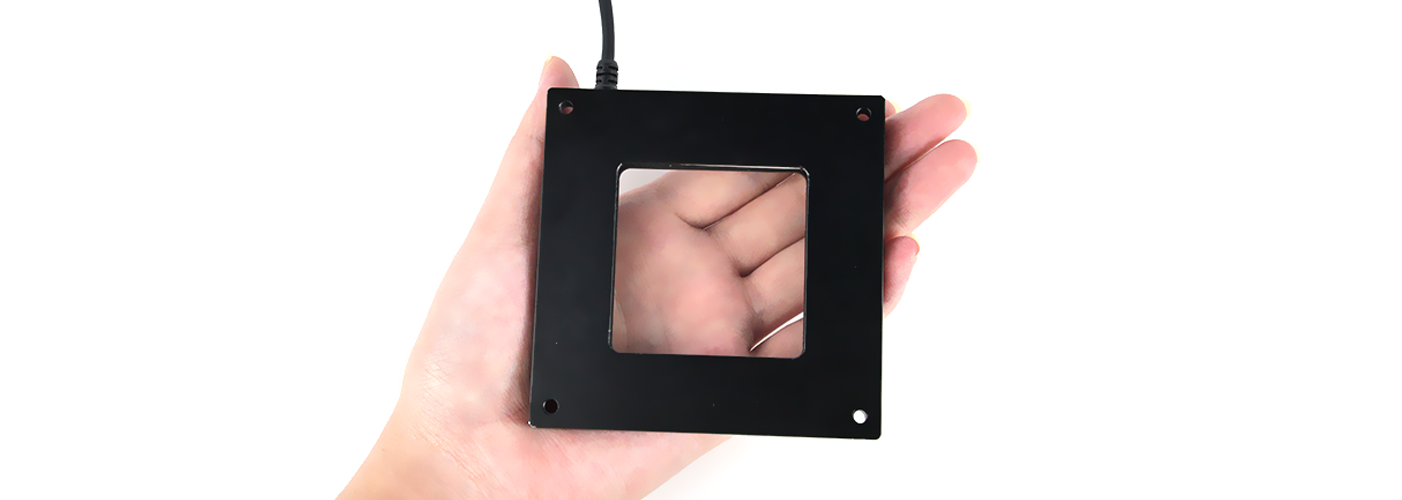

Compact and Lightweight Design: Combines coaxial and dome lighting effects in a slim, portable package, perfect for tight production spaces.

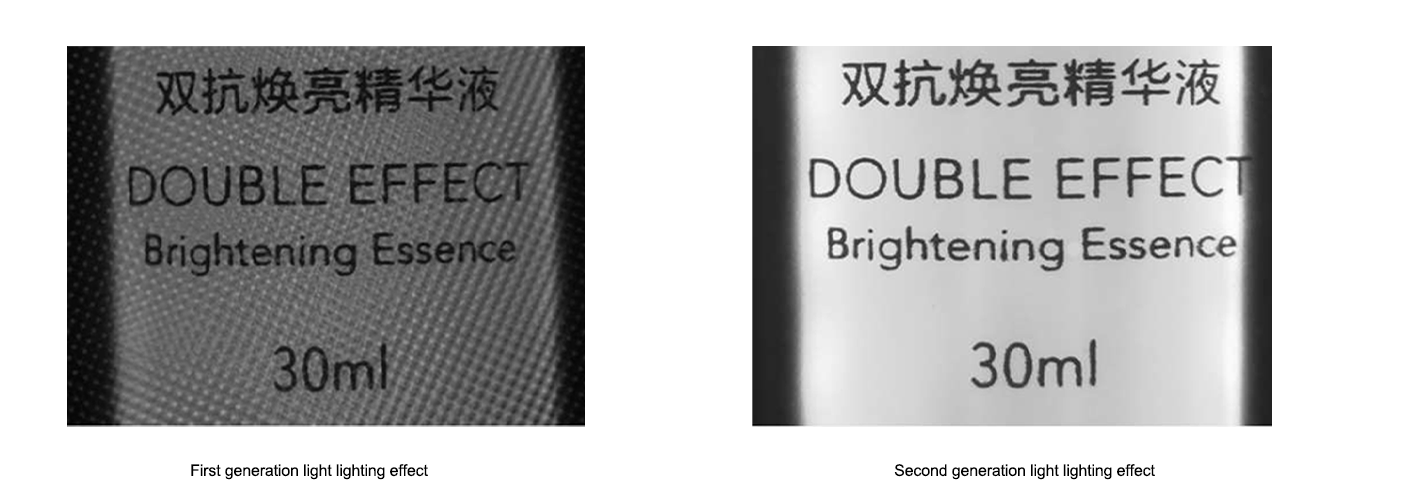

Eliminates Moiré Ripples: Unlike first-generation lights, it removes distracting wave patterns, delivering cleaner images.

High-Precision Light Guide Plate: Paired with high-brightness LED beads, it creates a clear, bright field of view for precise inspections.

These features work together to minimize image inconsistencies caused by dotted patterns and ensure optimal imaging for machine vision systems.

Applications in Action

The second-generation flat dome light shines in a variety of industrial scenarios:

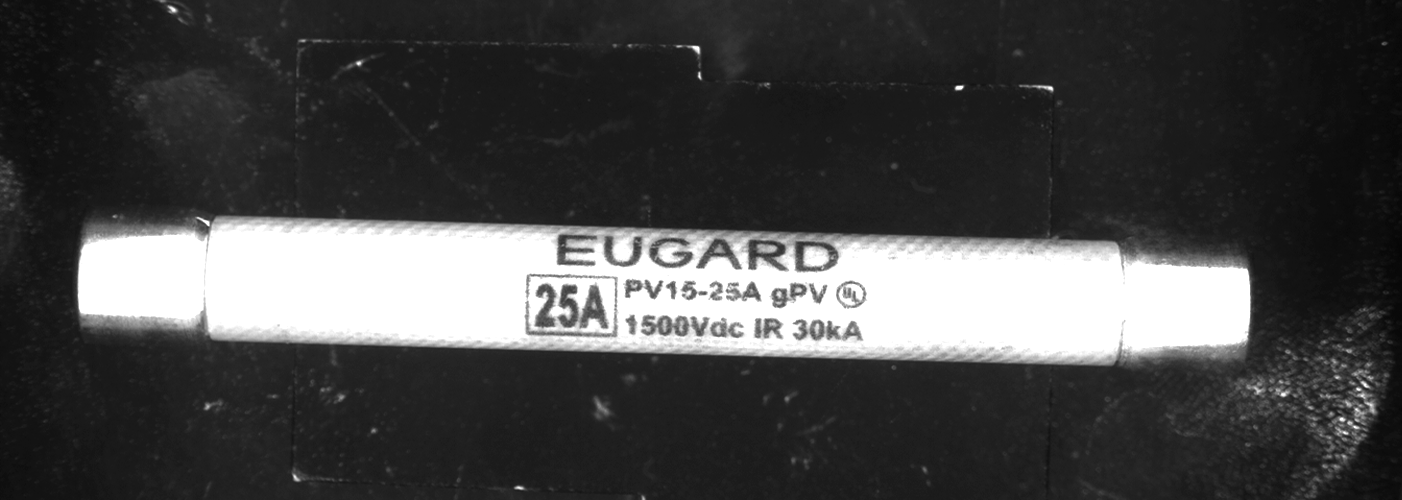

Character Recognition on Packaging: Ensures crisp, readable text on labels, even on reflective or uneven surfaces.

Metal Surface Inspection: Detects scratches, dents, or print imperfections on curved or concave metal parts with high clarity.

Glass Surface Inspection: Eliminates glare and highlights subtle defects, critical for industries like electronics or automotive.

For example, a packaging company using this light reported a 20% improvement in character recognition accuracy, reducing misreads and costly errors. Similarly, a metal parts manufacturer achieved clearer imaging of curved surfaces, catching defects that older lighting systems missed.

How It Improves on the First Generation

The first-generation flat dome lights had their strengths but often produced moiré ripples—wavy patterns that distorted images and frustrated inspections. The second generation solves this by using a high-precision light guide plate and optimized dotted patterns. These advancements ensure uniform illumination, eliminating ripples and delivering sharper, more reliable images. For a visual comparison of first- and second-generation performance, check out our detailed side-by-side analysis, showcasing the leap in image quality.

Why Upgrade to Second-Generation Lighting?

In industries where precision is non-negotiable, the second-generation flat dome light offers a competitive edge. Its ability to handle complex surfaces, reduce imaging errors, and integrate seamlessly into existing setups makes it a smart investment. As machine vision demands grow—driven by stricter quality standards and faster production lines—upgrading to advanced lighting ensures you stay ahead of the curve, delivering flawless products every time.