Hardware Selection: Key Considerations for Choosing Industrial PCs

In machine vision applications, the Industrial PC (IPC) serves as the core computing device, undertaking multiple tasks such as image processing, data analysis, and equipment control. Since machine vision often plays a crucial role in industrial automation, quality inspection, and precision control, the selection of the IPC directly impacts the system's performance and reliability.

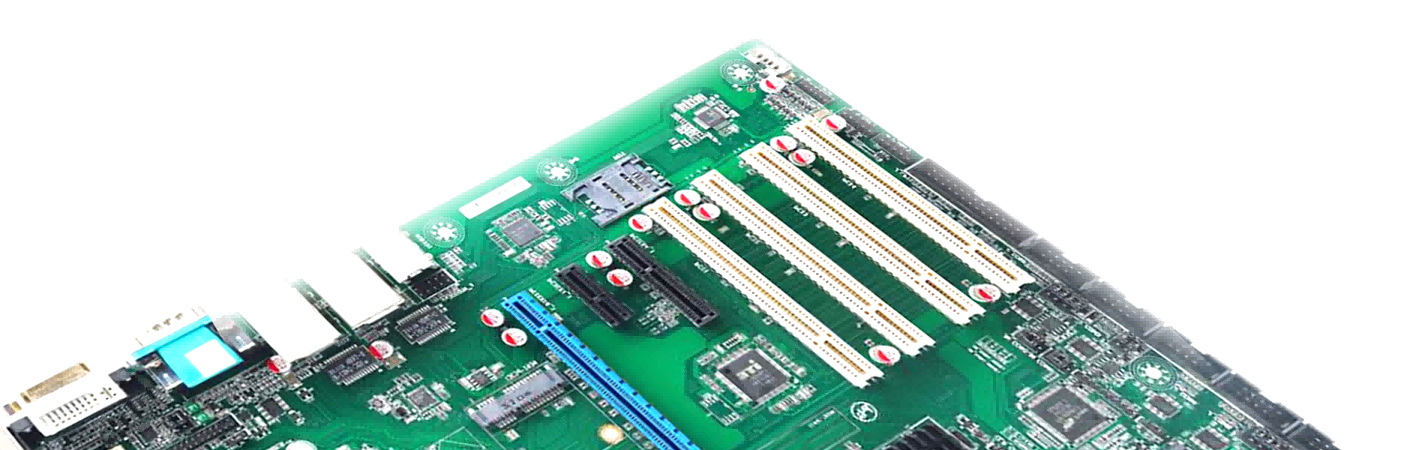

In a machine vision system, the image acquisition part mainly consists of an industrial camera, industrial lens, and light source combination, while the image processing part is implemented by image processing software. The frame grabber can be understood as the interface between the industrial camera (video source) and the computer (software). The images captured by the frame grabber are supplied to the computer or other processors for processing.

I. Application Scenarios and Requirements

Machine vision systems are widely used in fields such as industrial automation, quality inspection, robot guidance, and high-precision control. In these fields, the selection of the IPC needs to be determined based on the following points:

1. Image Processing Requirements

Machine vision systems need to efficiently process large amounts of image data, requiring the IPC to possess powerful processing capabilities.

2. Device Connectivity

It is often necessary to connect devices such as cameras, sensors, and PLCs through various interfaces. Therefore, the IPC needs to have sufficient input/output (I/O) interfaces.

3. Environmental Adaptability

In industrial environments, machine vision equipment may be exposed to harsh conditions such as high temperatures, dust, and vibration. Consequently, the IPC needs to have strong anti-interference capabilities and environmental adaptability.

II. Factors to Consider in IPC Selection

When selecting an IPC suitable for machine vision, the following aspects need to be considered:

1. Processing Performance

Machine vision systems typically require real-time image processing and computation, demanding the IPC to have powerful computing capabilities. Options include selecting models equipped with high-performance CPUs (such as Intel Core i-series, Xeon processors) and GPUs (such as NVIDIA GPU acceleration cards) to support image processing tasks.

2. Interface Requirements

The sampling rate reflects the speed and capability of the frame grabber in processing images. During image acquisition, attention must be paid to whether the frame grabber's sampling rate meets the requirements.

3. Environmental Adaptability

Machine vision systems often operate in relatively harsh locations like factory workshops. The IPC needs to possess capabilities such as shock resistance, dustproofing, waterproofing, and wide-temperature operation.

4. Real-Time Performance and Stability

Machine vision requires real-time response to external signals. Therefore, the IPC's operating system needs to support real-time requirements. Choosing a Real-Time Operating System (RTOS) or embedded operating system can ensure the timeliness and accuracy of data processing.

5.Expandability

As machine vision system applications continue to expand, the IPC needs to have good expandability, allowing for easy addition of hard drives, memory, network interfaces, etc., to support system function upgrades and optimization.

III. Comparison of IPC Hardware Configurations

|

Item |

IPC Requirement |

Description |

|

Processing Power |

Powerful CPU and GPU support |

Need to choose an IPC with high-performance CPU (e.g., Intel Core, Xeon) and GPU support. |

|

Interface Needs |

Powerful CPU and GPU support |

Need to provide interfaces such as USB, GigE, RS-232/485, Camera Link. |

|

Env. Adaptability |

Shockproof, dustproof, waterproof, wide-temp. |

IPC needs a rugged enclosure capable of withstanding harsh environments like temperature fluctuations, dust, and vibration. |

|

Real-Time Perf. |

Support for RTOS or embedded OS |

Provide an OS supporting real-time data processing to ensure real-time image processing. |

|

Expandability |

Support modular design & hardware expansion |

Support addition of extra memory, hard drives, I/O interfaces for convenient system expansion. |

IV. Recommended Typical Hardware Configurations

When selecting an IPC for machine vision applications, below are several recommended typical hardware configurations to help choose the appropriate IPC based on different needs:

|

Application Scenario |

Recommended Hardware Configuration |

Reason |

|

High-Precision Image Proc. |

High-perf. CPU (e.g., Intel Core i7/i9) + GPU (e.g., NVIDIA Jetson) |

High-performance processors and GPU accelerate image processing tasks, adapting to complex vision tasks. |

|

Multi-Camera Sync. Monitor. |

Multi-interface (GigE, USB3.0), high-speed network |

Multiple interfaces support real-time data acquisition and transmission from multiple cameras, ensuring no latency. |

|

Operation in Harsh Env. |

Shock/dust-proof enclosure, wide-temp. (-20°C~60°C) |

Suitable for harsh environments like high temp, humidity, dust; ensures long-term stable operation. |

|

Edge Computing Needs |

High-perf. embedded system (e.g., ARM architecture) |

Edge computing tasks require fast local processing capability to reduce network latency. |

|

Ind. Automation Control |

Multiple I/O interfaces (e.g., RS-232, CAN bus) |

IPC needs to support access and control of multiple industrial devices, ensuring efficient communication between equipment. |

V. Summary and Selection Recommendations

In machine vision applications, IPC selection should focus on multiple aspects including processing performance, interface support, environmental adaptability, real-time performance, and expandability. A suitable IPC must not only meet the needs of efficient image processing but also ensure stable operation in harsh environments, possessing sufficient connectivity and expansion potential.

Selection Recommendations:

1. For high-precision image processing and complex tasks, choose an IPC equipped with a powerful CPU and GPU.

2. For multiple cameras and real-time monitoring, the IPC needs to have rich network and interface support.

3. Farsh environments, choose an IPC with shockproof, dustpror applications in hoof, waterproof functions and supporting a wide temperature range.

4. For applications requiring edge computing, choose an embedded system or compact IPC to achieve rapid data processing.