Optical Design: The Often Overlooked Issue of Stray Light

In the machine vision projects, the quality of optical design directly determines whether a system can operate efficiently and accurately. However, the presence of stray light can severely threaten imaging quality.

Whether in high-precision industrial inspection or real-time recognition scenarios for autonomous driving, stray light-induced issues such as ghosting, rainbow flares, and image fogging can lead to misjudgments and reduced accuracy.

So, when designing a machine vision optical system, what factors related to stray light should be considered, and what solutions are available?

I. Sources and Hazards of Stray Light

Stray light refers to harmful light that deviates from the normal imaging path, and its causes are relatively complex.

Common sources of stray light include:

1. Lens-related issues: Inconsistent coating, excessively high reflectivity, or poor surface finish can cause multiple reflections on the lens surface.

2. Mechanical components: Inadequate oxidation blackening, lack of internal anti-reflective design, and poorly manufactured aperture dimensions can also lead to stray light.

3. Optical design flaws: Hidden risks in the optical path structure are another significant source of stray light.

The impact of stray light on imaging quality cannot be ignored. It will :

1. Reduce image resolution and contrast, blurring details and severely affecting detection accuracy.

2. Cause ghosting and virtual images, where false information obscures the real image, leading to misjudgments.

3. Under specific conditions, result in dispersion and rainbow flares, where colored spots around strong light sources interfere with image analysis.

4. Create an overall hazy image, making the picture appear gray and blurring the boundaries between black and white areas. Color images may also suffer from fogging.

5. When there is an angle between the optical axis of the lens and the light source in the field of view, smearing may occur, covering the original area and causing loss of information.

II. Solutions to Address Stray Light

1. Optimize Optical Design:

Use high-quality coatings: Applying low-reflectivity multilayer coatings on lens surfaces can effectively reduce light reflection.

Rational optical path design: Optimize the optical path structure through ray tracing simulation to prevent stray light from entering the imaging area.

Use anti-stray light apertures: Adding apertures to the optical path can block deviant light.

2. Control External Light Sources:

Block strong external light sources: Use lens hoods or baffles in the shooting environment to reduce direct exposure to strong light.

Adjust light source angles: Avoid excessive angles between the light source and the lens optical axis to minimize reflected light entering the lens.

Use polarizers: Filter light in specific directions to reduce stray light interference.

3. Improve Mechanical Structure:

Optimize components around the optical system: Apply anti-reflective treatments, such as spraying black matte paint, to reduce reflections.

Add light-blocking structures: Prevent stray light from entering the imaging area.

4. Post-Processing Image Correction:

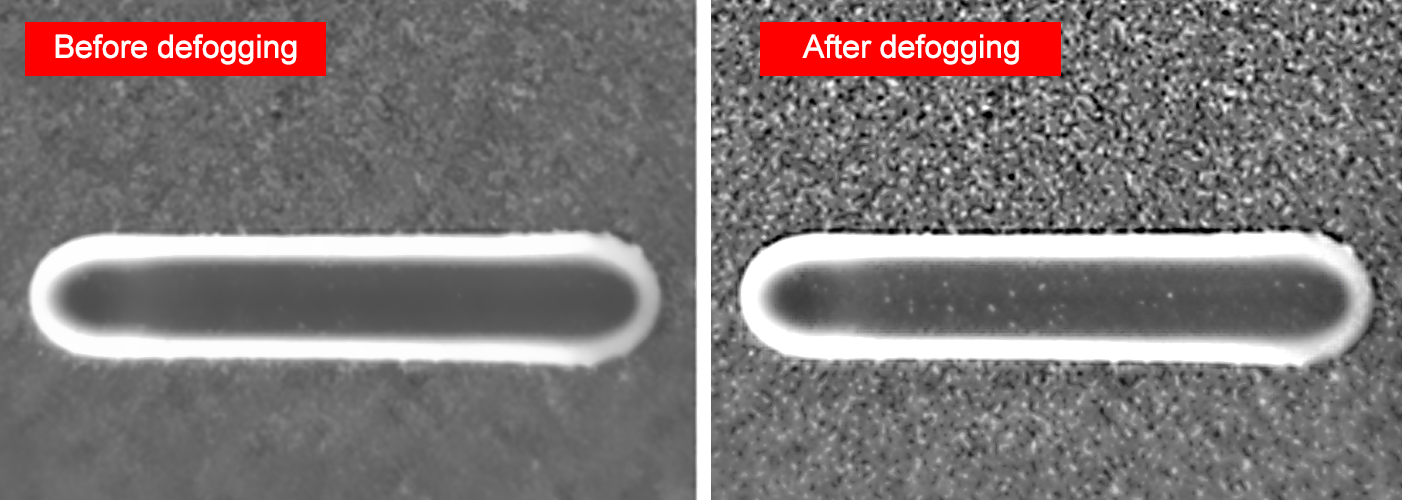

For unavoidable scenarios, use image processing algorithms such as defogging and denoising to mitigate the impact of stray light.

Dynamically adjust camera exposure parameters based on ambient light intensity to avoid overexposure or underexposure.

III. Practical Case

In an industrial inspection project, the client reported severe image fogging under strong ambient light, leading to a significant drop in detection accuracy. Analysis revealed that the stray light primarily originated from reflections inside the lens and direct exposure to external strong light.

The following measures were taken:

- Added anti-reflective coatings inside the lens to reduce reflections from mechanical components.

- Installed lens hoods in the shooting environment to block external strong light.

- Optimized the optical design by adding anti-stray light apertures.

After these improvements, image quality significantly improved, and detection accuracy returned to the expected level.

IV. Conclusion

Factors to Consider When Selecting a Frame Grabber:

Stray light is a critical issue in machine vision optical design that cannot be overlooked, as it directly impacts imaging quality and system performance.

To minimize stray light, an imaging lens requires anti-stray light efforts across all stages: optical design, structural design, lens processing, mechanical component processing, and assembly.

By optimizing optical design, controlling external light sources, improving mechanical structures, and incorporating post-processing image correction, the interference of stray light can be effectively reduced, enhancing system stability and accuracy.

In practical applications, solutions should be flexibly selected based on specific scenarios and requirements to ensure the stable operation of machine vision systems in various complex environments.