Revolutionizing Quality Control: The Power of 360-Degree Panoramic Imaging and AI

The factory floor is changing. Today, manufacturers are facing unprecedented pressure to produce flawless products at scale. Traditional quality control methods—often manual and time-consuming—simply can't keep up. The human eye, while remarkable, is prone to fatigue and can miss minute defects.

Enter a powerful new synergy: 360-degree panoramic imaging and AI-driven defect detection. This isn't just an upgrade; it's a complete paradigm shift that’s transforming how we ensure product quality and integrity.

The Challenge of The Traditional View

Think about a standard machine vision system. It uses a camera with a limited field of view, much like a person looking at an object from a single angle. To inspect all sides of an object—like the inner and outer walls of a pipe or the entire surface of a small component—you'd need multiple cameras, a complex setup, and sophisticated software to stitch together the images. This approach is costly, prone to blind spots, and inefficient. It's a logistical puzzle that limits throughput and can still miss critical flaws.

A Single Lens, A Complete Picture

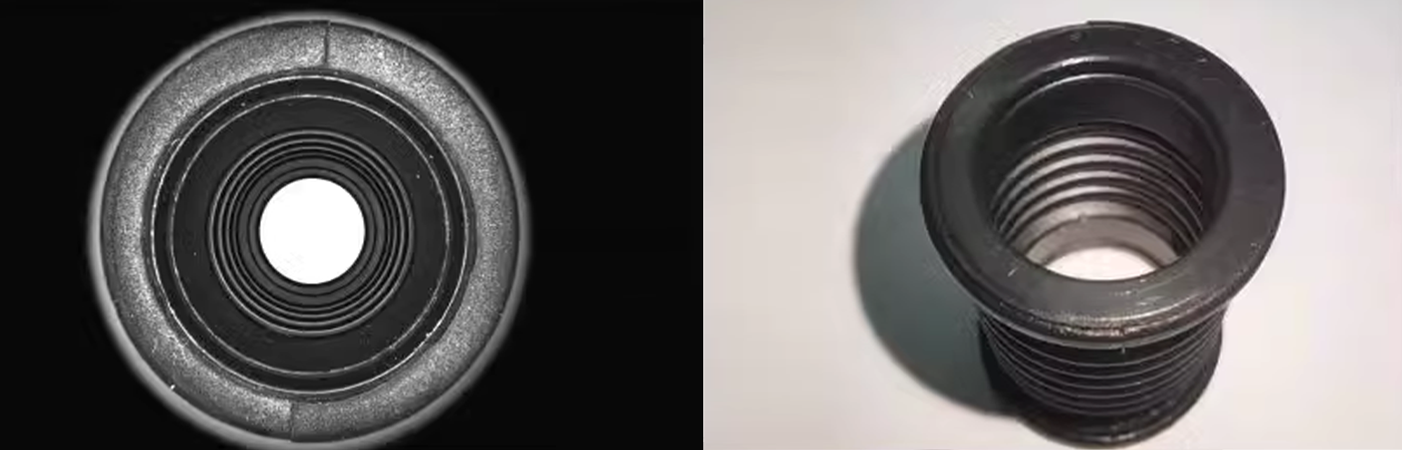

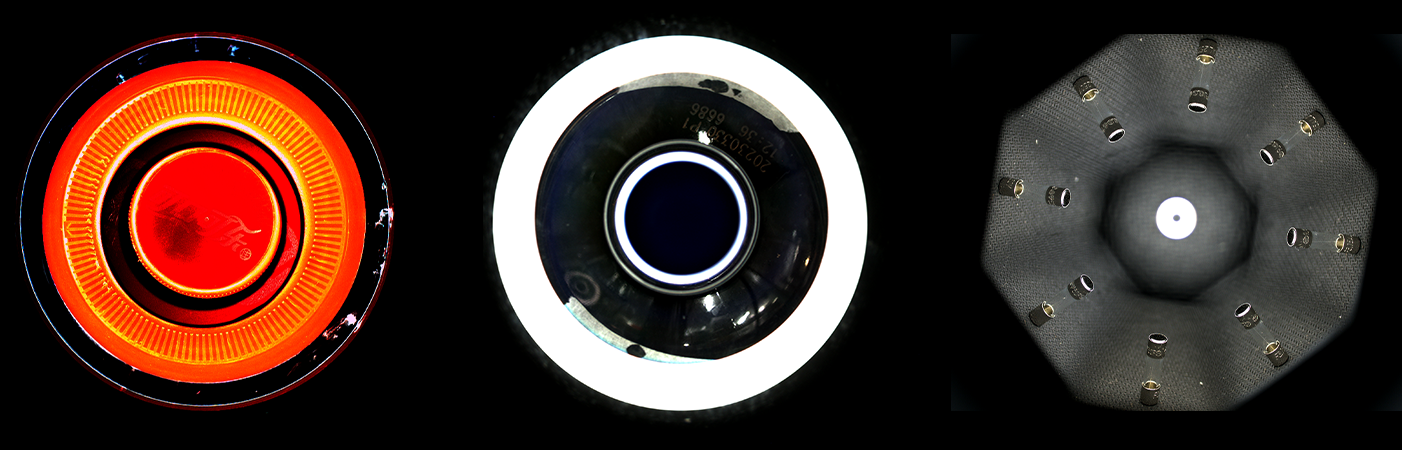

Panoramic imaging technology solves this problem by capturing a full 360-degree view of an object in a single shot. This is often achieved with specialized lenses, such as catadioptric or hypercentric lenses, that use mirrors to reflect a complete view of the object's surfaces onto the camera sensor. This unique setup allows for the inspection of both outer and inner walls of hollow objects from a single, external vantage point, significantly simplifying the inspection process.

The benefits are immediate and tangible:

1. Complete Coverage: Eliminates blind spots, ensuring no defect goes unnoticed.

2. Increased Efficiency: One lens and one camera replace multiple setups, dramatically reducing hardware costs and complexity.

3. High-Speed Inspection: Capturing a full-circle view in a single image allows for faster processing on high-volume production lines.

The AI-Powered Inspection Engine

A panoramic image is a goldmine of data, but it's the AI that turns that data into actionable insights. AI algorithms, particularly those based on deep learning and convolutional neural networks (CNNs), are trained on vast datasets of both perfect and defective products. This training enables them to recognize and classify a wide range of defects, from microscopic scratches and cracks to subtle deformities and material inconsistencies.

When a panoramic image is fed into the AI system, it can:

1. Analyze the entire surface: The AI quickly scans the complete 360-degree view, detecting anomalies across the entire object.

2. Categorize defects: It can differentiate between a scratch, a chip, or a discoloration, providing detailed information for quality control reports.

3. Improve over time: As the system processes more images, it learns from new data, becoming even more accurate and robust at identifying defects that might have been previously unknown.

The combination of panoramic lenses with AI creates an inspection system that is not only faster and more comprehensive than manual inspection but also more precise and consistent than traditional machine vision. It's an intelligent solution that doesn't just find problems—it helps you understand them, leading to improved manufacturing processes and higher quality products.

Your Quality Control Transformation Starts Here

The future of manufacturing is one where quality is not just inspected, but guaranteed. By adopting 360-degree panoramic imaging and AI defect detection, your business can reduce waste, minimize costly rework, and build a reputation for uncompromising quality. Don't let your business be left behind. Explore how these technologies can integrate into your workflow and take the first step towards a new era of precision manufacturing.