Izbiro svetilnikov za strojno vizijo: LED ali koaksialni za različne zahteve pri pregledu

Izbiro svetilnikov za strojno vizijo: LED ali koaksialni za različne zahteve pri pregledu

Zakaj izbira osvetlitve določa uspeh industrijskega pregledovanja Osjetliške luči so temelj preciznega pregledovanja – ne le dodatki. Za strokovnjake v proizvodnji neposredno vplivajo izbire osvetlitve na razpoznavne mere defektov, točnost merjenja in skozišče proizvodnje. Izbor med večkratno uporabljivimi LED osvetlitev in specializiranimi koaksialna osvetlitev lahko določi, ali bodo mikroskopske škrabe na medicinskih napravah ali vtisnjene kodi na pakiranju vidne za vaš vizualni sistem. V HIFLY opazujemo, da imajo strankarji avtomobilske in elektronske industrije dragoceno povratne prijeme, ko splošna osvetlitev skrije kritične pomanjkljivosti. Prilagoditev tehnologije konkretnemu nalogu ni izbirna; je bistvena za ROI.

Ključne učinke za industrijske kupce

Ko ocenjujete vizualne luči, si B2B odločevalci pritožijo:

- Razpoznavanje defektov Nedovolj dobra osvetlitev lahko skrije jemne trsove na kovinskih površinah ali slaboznačne Data Matrix kode. Nalogo prilagojena osvetlitev poviša kontrast, da se zmanjša število izpuščenih primerek.

- Okoljska trajnost Skrbniki montažnih vrstic z visoko vibracijo ali čistih sob za polprevodnike zahtevajo robustne dizajne s IP-ocenjenim zaklepom pred prahom in vstopom hladiča.

- Gibalna fleksibilnost Retrofits proizvodnje pogosto zahtevajo kompaktne oblike. Koaksialna svetloba prihrani prostor v robotačkih celicah, medtem ko modulski LED nizovi prilagajajo nepravilnim delom.

- Ekonomika operacij Dolgoročne razmisleke o TCO se razširijo za pred hkratno ceno. LED-ji tipično ponujajo življenjske dobe nad 50.000 ur z nižjo porabo moči v primerjavi s specializiranimi koaksialnimi sistemii.

Natančno ujemanje: LED vs. Koaksialno za branje industrijskih nalog

Kdaj dostopa LED osvetlitev največje vrednosti

Inženirska ekipa HIFLY potrjuje LED rešitve se izjemno izkazujejo v teh scenarijih:

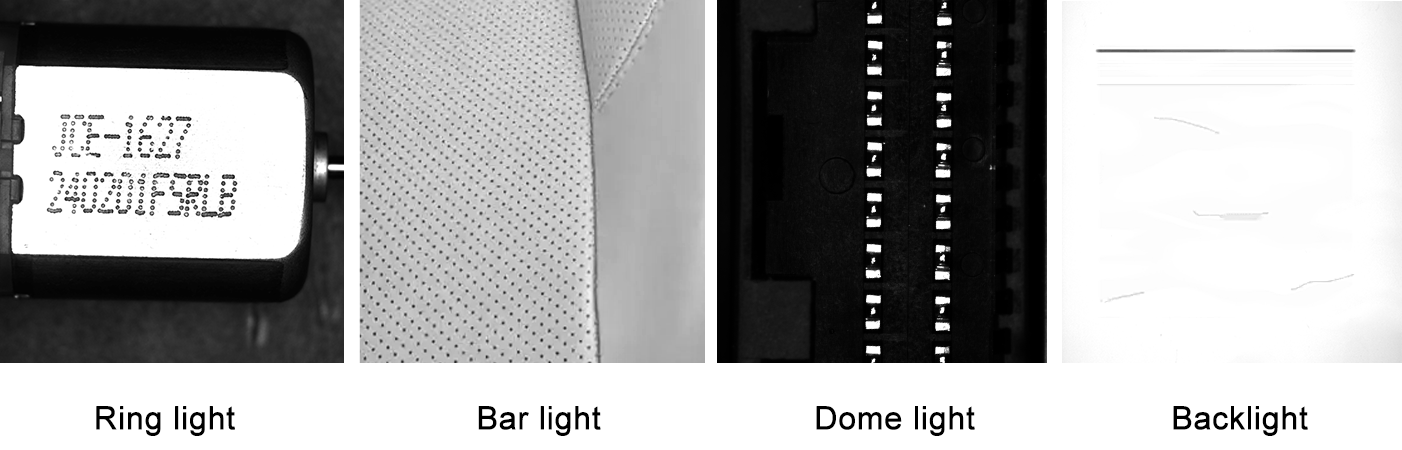

- Branje znakov/koda Razsežne krožne svetlobe zagotavljajo senčno svetlobo za OCR/DPM na farmacevtski embalazi ali komponentah PCB. En proizvajalec medicinskih naprav je zmanjšal nepreciznosti branja za 40 % z uporabo programabilnega nadzora intenzitete.

- Preverjanje strukture Svetilne črte pod kotenjem poudarjajo razlike v žarki na kožnih sedežih ali lihovinskih končnih ploskvah. Smerne sence odkrivajo zapadline, ki so nevidne pod okoljskim svetlobnim osvetljenjem.

- Potrditev hitrega montažnega procesa Kupolna svetila omogočajo slikanje z hitrostjo >200fps za preverjanje prisotnosti avtomobilskega dela. Enakomerna difuzija izbriše odbleske na povezavah.

- Preverjanje prozornega pakiranja Difuzirana ozadja odkrivajo nepopolnosti segrevanja v jemnih točkicah hrane/pija preko kontrasta silhuete.

Kjer postaja coaxialno osvetljevanje pomembno

Coaxialne osvetlitve rešujejo edinstvene izzive v preciznih industrijah:

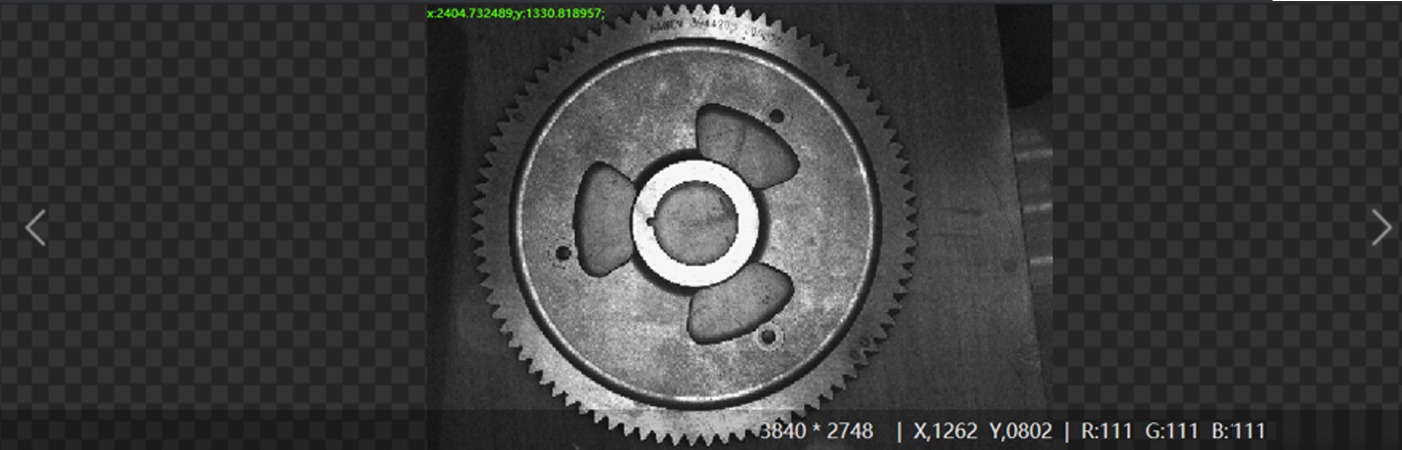

- Zaznavanje defektov na odblesčivih kovinah S poravnanim osvetljenjem z osjo kamere preobrazijo coaxialna svetla odbleske na delavinih avtomobilskih delih v uporabno svetlo – odkrivajo pod-mikronske drsne jame kot temne značke.

- Preverjanje polprevodniških ploskev Časticna onesnaženja na poliranim siliciju postanejo z vidljivostjo >90% pod coaxialnimi žarki, kar je ključno za izboljšanje učinkovitosti.

- Kontrola kakovosti steklene plošče Mikrotrotine na zaslonu mobilnega telefona absorbirajo coaxialno osvetlitev, prikazujejo se kot očitne defektnosti pred jasnim ozadjem.

- Kosmetična preverjanja plastike s spejšnim končanjem Tokovine na leskljavih avtomobilskeh dekoracijah postanejo vidne brez motnje od točkavega odbleska.

Strategije prilagajanja za zahtevne industrijske potrebe

Proizvodni okolja pogosto zahtevajo prilagojene konfiguracije vizualnega svetla:

Hibridne arhitekture osvetlitve Združevanje koaksialne in LED tehnologije bi lahko rešilo večstranske naloge. Proizvajalec obeh je hkrati meril razsežnosti profilov zubov (prek LED ozadnje svetlobe) in pomanjkljivosti površinske poliranja (prek koaksialne metode) v eni postaji.

Inženiring po meri aplikacij Neplave površine morda zahtevajo:

- Prilagojeni difuzorji za pregled krivuljastega stekla

- Večobremenjeni LED poljubici za določanje debeline obloge

- Stroboski kontroleri sinhronizirani s hitrodelnim transportnim trakom

Inteligentna integracija upravljanja Sistemi videa dosegujejo usklajenost prek:

- Prilagoditev intenzitete povezane z PLC, ki kompensira spremembe okoljskih pogojev

- Protokoli osvetlitve na podlagi receptov shranjenih v bazi MES

- Samodejni kalibracijski zaporedji, ki minimizirajo čas neaktivnosti pri nastavitvi

Tehnologije osvetlitve pripravljene za prihodnost

Napredki, ki povečujejo industrijsko uporabnost vključujejo:

- Prilagodljive kontrolere osvetlitve s AI Samodejne prilagoditve intensenosti/ kota v odgovoru na površinske spremembe

- Sistemi večspektralnega slikanja UV/IR diode, ki odkrivajo lastnosti materialov pod površino, nevidne v vidnem svetlu

- Oblikovanja, ustreznega za porabo energije Arhitektura z nizko porabo energije, ki izpolnjuje cilje trajnostnosti ISO 50001 brez da bi se zmanjšala svetlobnost

Vaše nalogo določa vašo tehnologijo Niti LED, niti koaksialna osvetlitev splošno ne prevladuje druga – uspeh leži v natančni prilagoditvi zahtevam pregledave. Za potrditev PCB, povedi v tekstilu ali pomanjkljivosti v pakiranju, LED rešitve dostavljajo fleksibilno, stroškovno učinkovito izvedbo. Ko se spopadajo s poliranimi kovinami, polprevodniškimi ploščami ali prikaznim steklom, koaksialna osvetlitev postane nerešljivo orodje za odkrivanje defektov.

V HIFLY inženiramo svetilne sisteme kot orodja za reševanje problemov. S predmetnimi komponentami za brezplačno testiranje aplikacij , proizvajalci preskočijo teoretične predpostavke in uporabijo empirično preverjene konfiguracije osvetlitve. Industrijska pregledovanja ni o iskanju "najjasnejših" svetil – gre za načrtovanje fotonskih pogojev, kjer defekti izgubijo svoje skrite mesta.