ซอฟต์แวร์อัลกอริทึมการมองเห็นของเครื่องจักรในโรงงานประยุกต์ใช้จริง

ภายในสภาพแวดล้อมที่วุ่นวายของโรงงานจริง ซอฟต์แวร์อัลกอริทึมการมองเห็นของเครื่องจักรได้ปรากฏตัวขึ้นเป็นสินทรัพย์สำคัญ ซึ่งเปลี่ยนกระบวนการทำงานการผลิตอย่างสิ้นเชิงด้วยฟังก์ชันที่หลากหลายและแม่นยำ โซลูชันซอฟต์แวร์เหล่านี้ พร้อมด้วยอัลกอริทึมที่ซับซ้อน ได้ก้าวเลยการตรวจสอบพื้นฐานไปสู่การครอบคลุมคุณสมบัติที่หลากหลาย เช่น การตรวจจับเส้นรอบรูป การวัดค่าที่แม่นยำ และอื่นๆ อีกมากมาย ซึ่งทั้งหมดนี้มีส่วนช่วยเพิ่มประสิทธิภาพในการควบคุมคุณภาพและประสิทธิภาพการดำเนินงาน

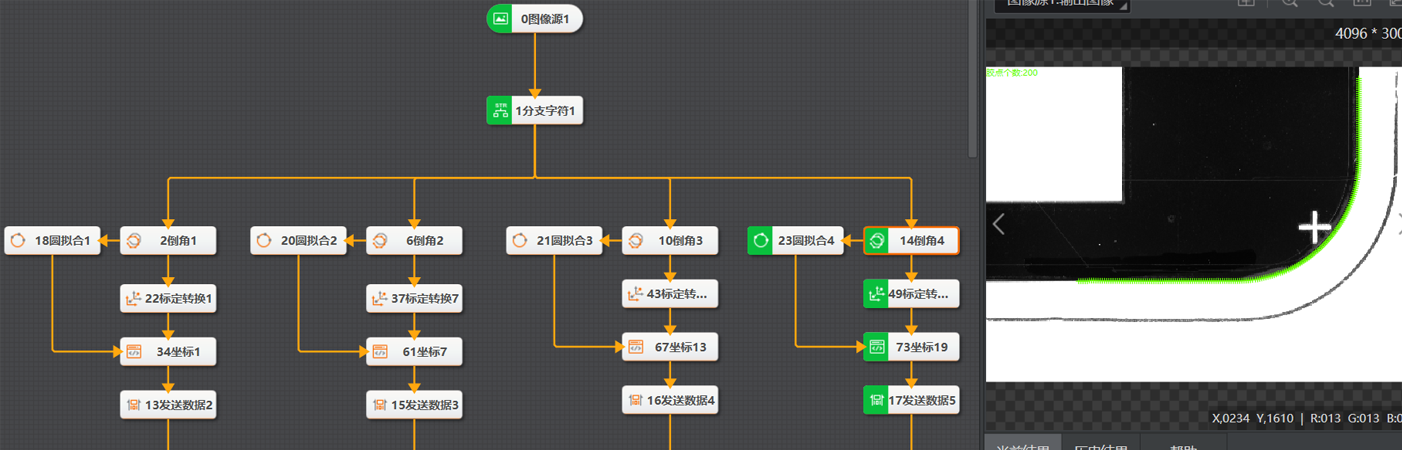

การตรวจจับเส้นขอบ (Contour detection) เป็นฟังก์ชันสำคัญของซอฟต์แวร์อัลกอริทึมการมองเห็นด้วยเครื่องในโรงงาน มันช่วยให้ระบบสามารถระบุรูปร่างของวัตถุบนสายการผลิตได้อย่างแม่นยำ ตัวอย่างเช่น เมื่อผลิตชิ้นส่วนโลหะที่มีรูปร่างซับซ้อน ซอฟต์แวร์จะสามารถแยกเส้นขอบของแต่ละชิ้นส่วนจากภาพที่ถ่ายได้อย่างรวดเร็วและแม่นยำ สิ่งนี้ทำให้สามารถตรวจสอบได้ทันทีว่ารูปร่างของชิ้นส่วนนั้นตรงตามข้อกำหนดการออกแบบหรือไม่ หากพบความผิดปกติในเส้นขอบ เช่น ขอบที่ขาดหายไปหรือส่วนที่ยื่นออกมาโดยไม่คาดคิด ซอฟต์แวร์จะระบุชิ้นส่วนนั้นเป็นชิ้นส่วนที่ชำรุดทันที เพื่อป้องกันไม่ให้ชิ้นส่วนนั้นเข้าสู่ขั้นตอนการผลิตถัดไป การตรวจจับความผิดปกติของรูปร่างอย่างรวดเร็วนี้ช่วยให้มั่นใจได้ว่าจะมีเพียงชิ้นส่วนที่มีรูปร่างถูกต้องเท่านั้นที่จะถูกส่งต่อไป ลดโอกาสที่จะเกิดปัญหาในการประกอบในขั้นตอนต่อมา

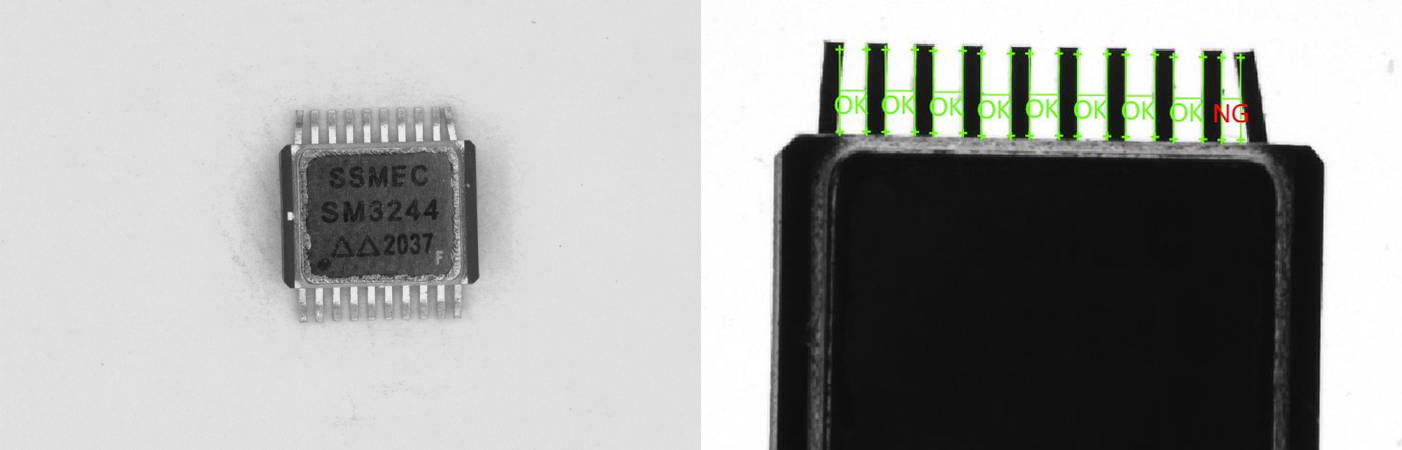

การวัดค่าที่แม่นยำคืออีกหนึ่งความสามารถที่สำคัญซึ่งซอฟต์แวร์อัลกอริทึมระบบภาพจักรกล (Machine Vision) นำมาสู่พื้นที่การผลิตในโรงงาน การวัดค่าแบบด้วยมือที่เคยปฏิบัติกันมาไม่เพียงแต่ใช้เวลามากเท่านั้น แต่ยังมีแนวโน้มเกิดข้อผิดพลาดจากปัจจัยมนุษย์ โดยเฉพาะเมื่อต้องทำงานกับชิ้นส่วนขนาดเล็กหรือมีลวดลายซับซ้อน ระบบภาพจักรกลสามารถดำเนินการวัดค่าที่มีความแม่นยำสูงในหลายมิติ เช่น ความยาว ความกว้าง ความสูง เส้นผ่านศูนย์กลาง และมุมต่าง ๆ ได้อย่างเที่ยงตรงและสม่ำเสมอ ยกตัวอย่างเช่น กระบวนการผลิตตัวเชื่อมต่อทางอิเล็กทรอนิกส์ (Electronic Connectors) ซอฟต์แวร์สามารถวัดระยะห่างระหว่างขาตัวเชื่อมต่อ (Pin Spacing) ความยาวของตัวเชื่อมต่อ และเส้นผ่านศูนย์กลางของขาแต่ละข้างได้ในระดับความแม่นยำที่สอดคล้องกับมาตรฐานอุตสาหกรรมที่เข้มงวดที่สุด ซึ่งจะช่วยให้ตัวเชื่อมต่อแต่ละชิ้นสามารถประกอบเข้ากับชิ้นส่วนคู่ติดตั้งได้อย่างพอดี ลดปัญหาการเชื่อมต่อที่ผิดพลาด และเพิ่มความน่าเชื่อถือโดยรวมของอุปกรณ์อิเล็กทรอนิกส์ที่นำไปใช้งาน

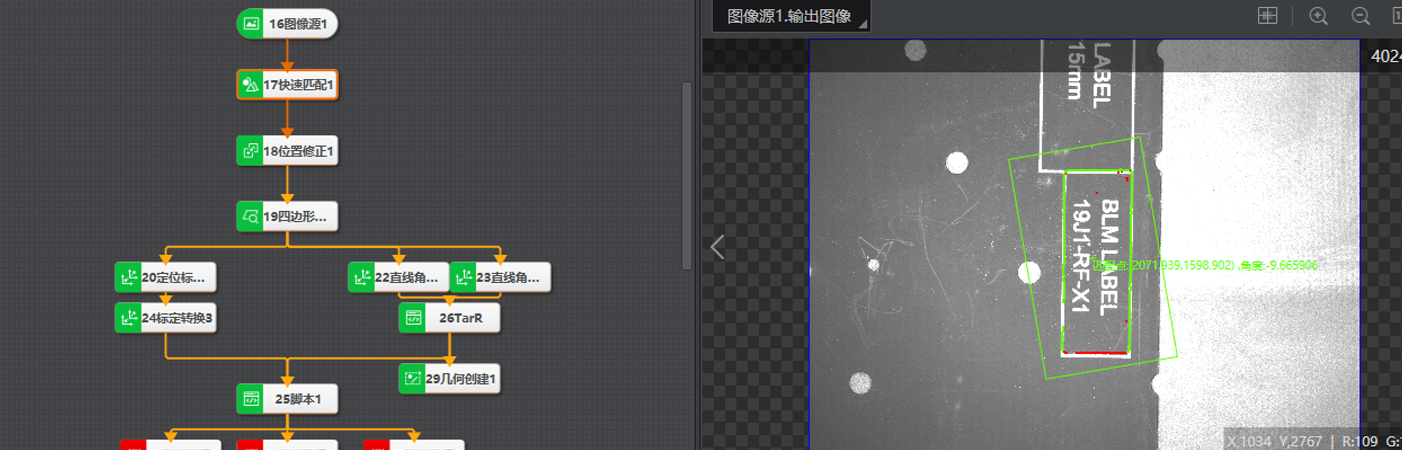

นอกจากการตรวจจับและวัดค่ารูปร่างแล้ว ซอฟต์แวร์อัลกอริทึมการมองเห็นด้วยเครื่องยังมีฟังก์ชันอื่นๆ ที่มีประโยชน์ในงานโรงงาน เช่น สามารถตรวจสอบพื้นผิวเพื่อตรวจหาข้อบกพร่องต่างๆ เช่น รอยเปื้อน รอยแตก หรือการกัดกร่อนบนพื้นผิวของผลิตภัณฑ์ ตัวอย่างเช่น ในกระบวนการผลิตแผงรถยนต์ ซอฟต์แวร์สามารถสแกนพื้นผิวทั้งหมดของแผง เพื่อระบุข้อบกพร่องเล็กๆ น้อยๆ ของสีที่อาจส่งผลต่อรูปลักษณ์และความทนทานของรถ นอกจากนี้ยังสามารถใช้งานในการจดจำรูปแบบ (pattern recognition) ซึ่งมีประโยชน์ในการตรวจสอบตำแหน่งของฉลาก โลโก้ หรือส่วนประกอบต่างๆ บนผลิตภัณฑ์ให้ถูกต้อง ทำให้มั่นใจได้ว่าผลิตภัณฑ์ทั้งหมดจะตรงตามข้อกำหนดทางด้านความสวยงามและฟังก์ชันการทำงานของแบรนด์

นอกจากนี้ ความสามารถของซอฟต์แวร์ในการทำงานบนสายการผลิตความเร็วสูง ถือเป็นข้อได้เปรียบอย่างมาก ซอฟต์แวร์สามารถประมวลผลภาพหลายภาพต่อวินาที ซึ่งสามารถทันกับการเคลื่อนที่ของผลิตภัณฑ์บนสายพานลำเลียงที่รวดเร็ว นั่นหมายความว่าสินค้าทุกชิ้นจะได้รับการตรวจสอบและวัดค่าแบบเรียลไทม์ โดยไม่ก่อให้เกิดการชะลอความเร็วในการผลิต สำหรับโรงงานอุตสาหกรรมขนาดใหญ่ ความสามารถในการประมวลผลที่รวดเร็วนี้มีความสำคัญอย่างยิ่งต่อการรักษาระดับประสิทธิภาพในการผลิต พร้อมทั้งรับประกันคุณภาพของสินค้า

การผสานรวมซอฟต์แวร์อัลกอริทึมระบบมองเห็นของเครื่องจักรเข้ากับการดำเนินงานในโรงงาน ยังนำไปสู่การตัดสินใจโดยอิงข้อมูล (Data-driven Decision-making) ซอฟต์แวร์จะรวบรวมและวิเคราะห์ข้อมูลในการตรวจสอบและวัดค่าจำนวนมาก ซึ่งให้ข้อมูลเชิงลึกที่มีคุณค่าเกี่ยวกับกระบวนการทำงาน ผู้ผลิตสามารถใช้ข้อมูลเหล่านี้เพื่อระบุแนวโน้ม เช่น ข้อบกพร่องที่เกิดซ้ำในล็อตสินค้าเฉพาะเจาะจง และดำเนินการอย่างรุกเร็วเพื่อแก้ไขสาเหตุหลัก วงจรการปรับปรุงอย่างต่อเนื่องนี้จะช่วยเพิ่มประสิทธิภาพกระบวนการผลิต ลดของเสีย และเพิ่มผลกำไรในที่สุด

สรุปได้ว่า ซอฟต์แวร์อัลกอริทึมการมองเห็นด้วยเครื่องมีบทบาทสำคัญในโรงงานจริง โดยนำเสนอชุดฟังก์ชันต่าง ๆ เช่น การตรวจจับเส้นขอบ การวัดที่แม่นยำ การตรวจสอบพื้นผิว และการจดจำรูปแบบ ความสามารถเหล่านี้ไม่เพียงแต่ช่วยรับรองคุณภาพของผลิตภัณฑ์เท่านั้น แต่ยังช่วยเพิ่มประสิทธิภาพในการผลิต ทำให้เกิดการปรับปรุงโดยอาศัยข้อมูล และส่งเสริมความสำเร็จโดยรวมของการดำเนินงานทางการผลิต ในขณะที่เทคโนโลยีก้าวหน้าไป เราสามารถคาดหวังได้ว่าโซลูชันซอฟต์แวร์เหล่านี้จะมีประสิทธิภาพและหลากหลายมากยิ่งขึ้น ซึ่งจะปฏิวัติสภาพแวดล้อมในโรงงานอย่างต่อเนื่อง