The Application of Machine Vision Lighting in Logistics

In the dynamic landscape of the logistics industry, where the volume of goods processed daily is staggering, efficiency and accuracy are the cornerstones of success. Machine vision technology has emerged as a game - changer, enabling automated operations that were once the domain of human labor. At the heart of this technology lies the machine vision lighting system, which plays a crucial role in ensuring that the images captured by cameras are of high enough quality for accurate analysis. This article delves into the diverse applications of machine vision lighting in different logistics scenarios.

Barcode and QR - code Reading in Sorting Hubs

Barcodes and QR - codes are the primary means of identifying packages in the logistics supply chain. However, the logistics environment poses numerous challenges to their accurate reading. Packages can have various surface materials, from reflective plastic wraps to rough and wrinkled cardboard.

For reflective surfaces, polarized light sources are a go - to solution. These sources filter out the specular reflections, allowing only the diffused light from the barcode to reach the camera. This results in a clear, high - contrast image of the barcode, making it easier for the machine vision system to decode. In high - speed sorting lines, where packages are moving rapidly, high - frequency strobe lights are used. These lights flash synchronously with the camera's shutter, effectively freezing the motion of the packages. This eliminates motion blur, ensuring that the barcode or QR - code can be read accurately even when the package is moving at a fast pace.

Volume Measurement of Packages

Determining the volume of packages is essential for calculating shipping costs and optimizing storage space in warehouses. However, the irregular shapes of many packages, especially soft - sided ones like envelopes or bags, make this a challenging task.

Backlighting is a widely used technique for volume measurement. A high - intensity backlight is placed behind the package. As the light passes through the package (if it is semi - transparent or has gaps, such as between a soft package and the conveyor belt), it creates a clear silhouette of the package on the camera's image sensor. For irregularly shaped items like furniture or bicycles, structured light sources, such as line lasers, are employed. The laser projects a pattern of lines onto the object's surface. As the object's shape varies, the laser lines are distorted. The machine vision system analyzes this distortion to reconstruct the 3D shape of the object and calculate its volume accurately.

Package Damage and Anomaly Detection

Ensuring the integrity of packages during transit is a key concern in logistics. Machine vision lighting can help detect damages such as tears in cardboard boxes, holes in plastic bags, or signs of liquid leakage.

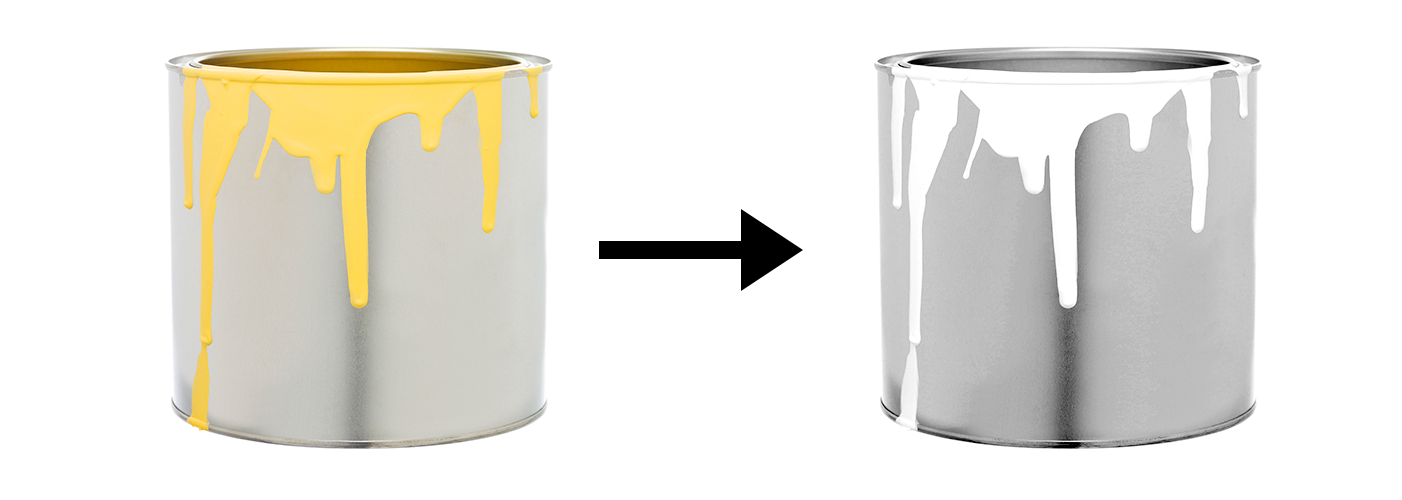

Dark - field lighting is effective for detecting surface defects. A low - angle light source is used to illuminate the package. Light rays are reflected away from the camera by the smooth surface of the undamaged part of the package. However, at the location of a defect, such as a tear or a hole, the light is scattered back towards the camera, creating a bright spot against a dark background. For detecting anomalies like liquid leakage or residue from a damaged label, multi - color light sources can be used. Different colors of light can enhance the contrast of specific substances. For example, a red light source may make a yellowish liquid leakage stain more visible, while a blue light source can highlight the residue left by a removed label.

Goods Identification and Classification in Warehouses

In large - scale warehouses, quickly identifying and classifying goods is crucial for efficient storage and retrieval. Machine vision lighting provides high - contrast illumination, which accentuates the features of the goods.

For example, when dealing with products of different shapes and colors, a well - designed diffused light source can evenly illuminate the items, making it easier for the machine vision system to recognize their characteristics. By analyzing the shape, color, and size of the goods, the system can automatically classify them into different categories and direct them to the appropriate storage locations. This not only speeds up the warehousing process but also reduces the risk of misplacement.

Guiding Automated Guided Vehicles (AGVs)

Automated Guided Vehicles (AGVs) are becoming increasingly common in modern logistics facilities. Machine vision lighting can assist AGVs in navigating through the warehouse environment.

By providing well - lit markers or lanes, the machine vision system on the AGV can accurately detect its position and orientation. For example, a series of bright, evenly spaced lights can be installed along the floor to mark the paths that the AGVs should follow. The AGV's camera, with the help of the appropriate lighting conditions, can easily identify these markers and adjust its course accordingly, ensuring smooth and accurate movement within the warehouse.

Conclusion

Machine vision lighting has revolutionized the logistics industry by enabling more accurate, efficient, and automated operations. From the initial sorting of packages based on barcode reading to the careful monitoring of package integrity and the smooth operation of AGVs in warehouses, the applications are vast and varied. As the logistics industry continues to grow and evolve, with the increasing demand for faster delivery times and higher service quality, the role of machine vision lighting will only become more critical. Future developments may include more intelligent lighting systems that can adapt to changing environmental conditions and object characteristics in real - time, further enhancing the capabilities of machine vision in logistics.