The Product Selection Process of A Machine Vision Project

Do you know what steps are involved in a comprehensive vision project selection process? Today, we' ll explore how to select components for a machine vision project.

- Get The Customer Requirements

When we receive a detection sample, what should we do first? Of course, it is to communicate with the customer about their requirements, as the project should strive to meet customer needs as much as possible. By understanding the specific detection requirements through communication, we can make the first choice based on whether the object is static or dynamic - that is, selecting the global or rolling shutter of the industrial camera. After all, for photographing dynamic objects, a global shutter is required.

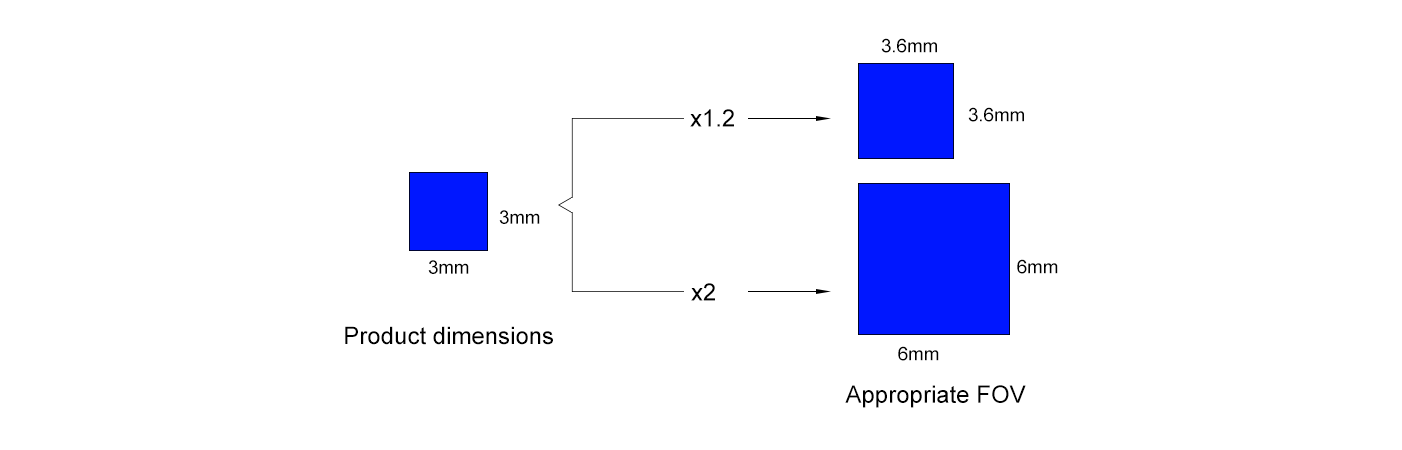

- Determine Field Of View (FOV)

Next, we need to determine the appropriate FOV size based on the product dimensions. For an image, the imaging FOV of the camera is generally most suitable to be 1.2 to 2 times the size of the product.

- Select Suitable Industrial Lenses

It is well known that industrial camera lenses include telecentric lenses and FA (Factory Automation) lenses, and the FOV calculation methods for different lenses vary, so we need to analyze specific situations. However, since FOV calculation is inseparable from the sensor size, we must first calculate the sensor dimensions.

Sensor size is calculated by multiplying the resolution by the pixel size. Take a 1.3-megapixel industrial camera as an example:

• Sensor width = 1280 × 4.8 μm = 6.144 mm

• Sensor height = 1024 × 4.8 μm = 4.915 mm

For telecentric lenses, the FOV is calculated as sensor size divided by the lens magnification. Using the same camera with a 0.5× telecentric lens:

• Imaging width = 6.144 mm ÷ 0.5 = 12.288 mm

• Imaging height = 4.915 mm ÷ 0.5 = 9.83 mm

For industrial FA lenses, the FOV calculation is sensor size × working distance ÷ focal length. Using the same camera with a working distance of 100 mm and a focal length of 8 mm:

• Horizontal width = 6.144 mm × 100 ÷ 8 = 76.8 mm

• Horizontal height = 4.915 mm × 100 ÷ 8 = 61.4 mm

All these calculations are aimed at selecting appropriate cameras and lenses based on the FOV and required precision. Therefore, the next step is to calculate the camera precision.

- Calculate The Industrial Camera Accuracy

For telecentric lenses, the theoretical precision of the camera equals the pixel size divided by the telecentric lens magnification. Continuing with the previous example (0.5× telecentric lens):

• Theoretical precision = 4.8 μm ÷ 0.5 = 9.6 μm

For industrial FA lenses, the theoretical precision is calculated as FOV ÷ resolution. When the FOV is 72 mm:

• Theoretical precision = 72 mm ÷ 1280 = 0.056 mm

The above are theoretical precisions, and there is often a significant difference between theory and practice. Therefore, actual precision requires further calculation. For example:

With front lighting, the actual precision is 3 to 5 times the theoretical precision.

With machine vision backlighting, the actual precision can reach 1 to 2 times the theoretical precision.

Higher precision can be achieved if the algorithm can sub - pixel interpolate.

As we all know, lighting is indispensable for visual inspection - good lighting can make half the success of a visual project. Therefore, it is necessary to select a light source of appropriate size for lighting tests. For example:

For machine vision ring lights, surface lights, or bowl lights, the light source size is generally 10% to 20% larger than the FOV.

For machine vision bar lights, the light source length is generally 20% to 30% longer than the FOV.

The above is the complete component selection process for a machine vision project. Following these steps, we can quickly determine the required products for the project. Alternatively, you can leave messages to us, and we will help you select the most suitable products for your project needs.