Kalibrasyon Hedef Türleri: Desenlerin ve Avantajlarının Karşılaştırmalı Analizi

Hassas kamera kalibrasyonu, makine/bilgisayar görüş uygulamalarının başarısı için temeldir. Kalibrasyon hedefinin seçimi, kalibrasyon doğruluğunu önemli ölçüde etkiler; ancak birden fazla desen türü mevcuttur—her biri farklı özelliklere sahiptir. Bu kılavuz, yaygın hedeflerin (satranç tahtası, dairesel ızgara ve CharuCo) avantajlarını ve sınırlamalarını analiz ederek optimal seçimi destekler.

I. Kalibrasyon Hedefi Boyutu: Kritik Hususlar

Bir kalibrasyon hedefinin fiziksel boyutları, özellikle Görüş Alanı (FOV) ile olan ilişkisi nedeniyle ölçüm doğruluğunu doğrudan etkiler. Temel prensipler şunlardır:

1. FOV Kapsamı: Sağlam bir kalibrasyon için hedef, ön yüzden görüntülendiğinde görüntü piksellerinin %50'sinden fazlasını kaplamalıdır. Küçük bir hedef, gözlemlenen özellikleri açıklayabilecek birden fazla kamera parametresi kombinasyonuna izin vererek model kısıtlamalarını zayıflatır.

2. Odak Stabilitesi: Kalibrasyon, sabit bir çalışma mesafesi varsayar. Odak uzaklığı veya diyafram açıklığının değiştirilmesi, odak kayması ve optik aberasyonlar nedeniyle önceki kalibrasyonu geçersiz kılar.

3. Pratik İpucu: FOV'nizi (Görüş Alanı) karşılayan bir hedef boyutu seçin. Büyük ölçekli ölçümler için (örneğin otomotiv denetimi), büyük boy hedefler veya çoklu pozisyonlu çekim kullanın.

II. Kalibrasyon Hedefi Türleri: Desenler ve Performans

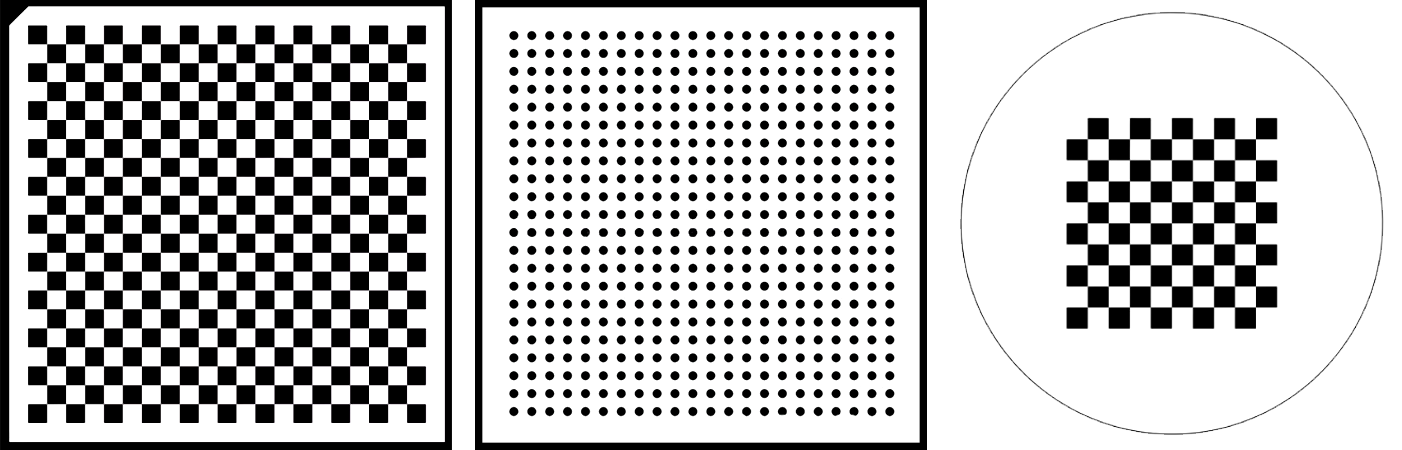

1. Satranç Tahtası Hedefleri

OpenCV, Halcon ve MATLAB tarafından desteklenen en yaygın desendir.

Algılama İş Akışı:

Görüntüyü ikili hale getirin → Dörtgenleri (koyu kareler) algılayın → Boyut/ızgara düzenliliğine göre süzgeçleyin → Kullanıcı tanımlı boyutlarla eşleştirin.

Avantajlar:

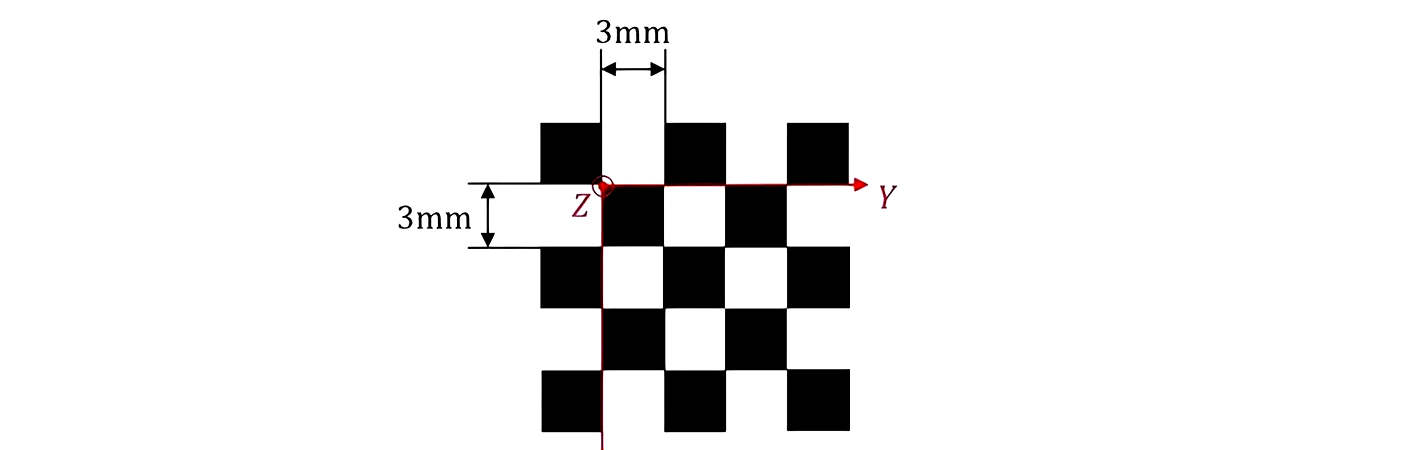

Alt piksel Doğruluğu: Köşeler (matematiksel olarak eyer noktaları) sonsuz küçüklüktedir ve bu da perspektif bozulma altında tarafsız konum belirlemeyi sağlar (hassasiyet: ±0,1 piksel).

Bozulma Modelleme: Yüksek kenar yoğunluğu, radyal/tanjant bozulma tahminini geliştirir.

Sınırlamalar:

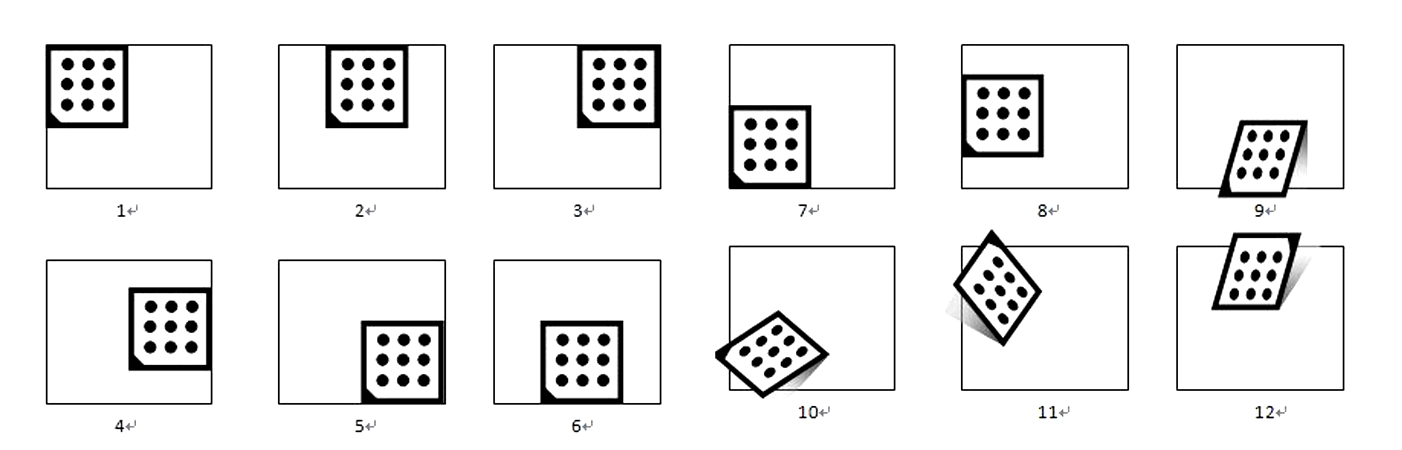

Tam Görünürlük Gerekli: Tüm tablo, tüm görüntülerde görünür olmalıdır; bu da köşe verisi toplamayı sınırlar (görüntü kenarlarında bozulma modellemesi için kritik öneme sahiptir).

Simetri Kısıtlaması: Stereo kalibrasyon için, 180° belirsizliğini önlemek amacıyla çift satır ve tek sütun (veya bunun tersi) olmasına dikkat edilmelidir.

En İyisi: Tam tablo görünürlüğünün mümkün olduğu tek kamera kalibrasyonu.

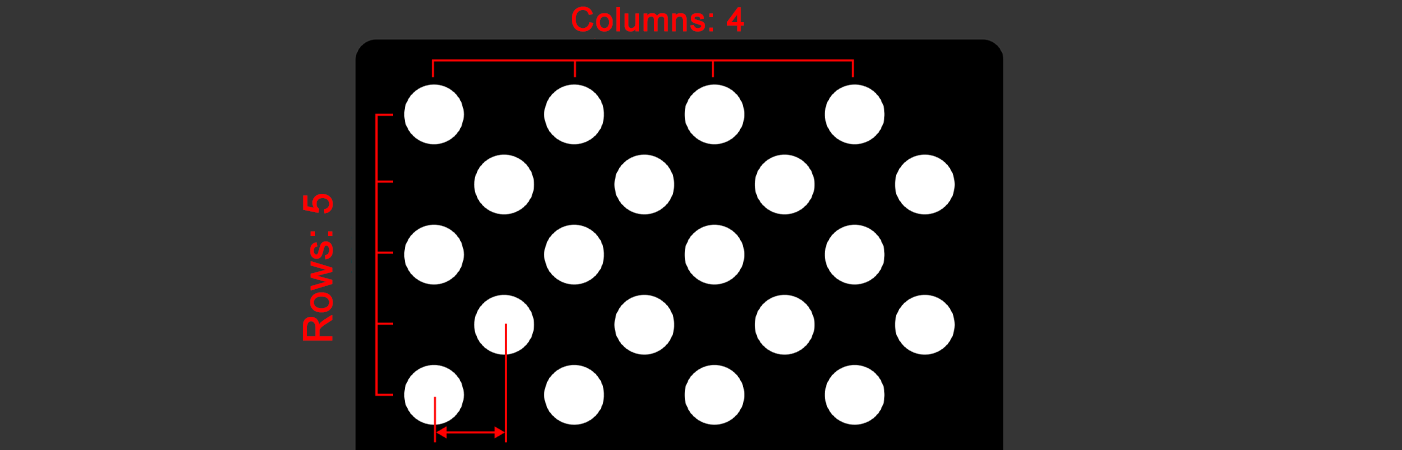

2. Dairesel Izgara Hedefleri

Yaygın varyantlar: Beyaz üzerinde siyah daireler ya da siyah üzerinde beyaz daireler.

Algılama İş Akışı:

"Blob" (leke) tespiti → Alan, dairesellik ve dışbükeylik kriterlerine göre filtreleme → Izgara yapısını tanımlama.

Avantajlar:

Gürültüye Direnç: Daire uydurma işlemi çevresel tüm piksellerden yararlanır ve bu da gürültüye duyarlılığı azaltır.

Kısmi Görünürlük Toleransı: Kısmen görünen daireler hâlâ tespit edilebilir.

Sınırlamalar:

Perspektif Sapması: Çemberler perspektif altında elipsler olarak projeksiyon gösterir. Lens distorsiyonu şekilleri daha da bozar ve küçük oturma hataları oluşur.

Stereo Belirsizlik: Simetrik gridler 180° belirsizliğe sahiptir; çoklu kamera kurulumları için asimetrik gridler kullanın.

En İyisi: Arka ışıklı uygulamalar ve değişken aydınlatmanın bulunduğu ortamlar.

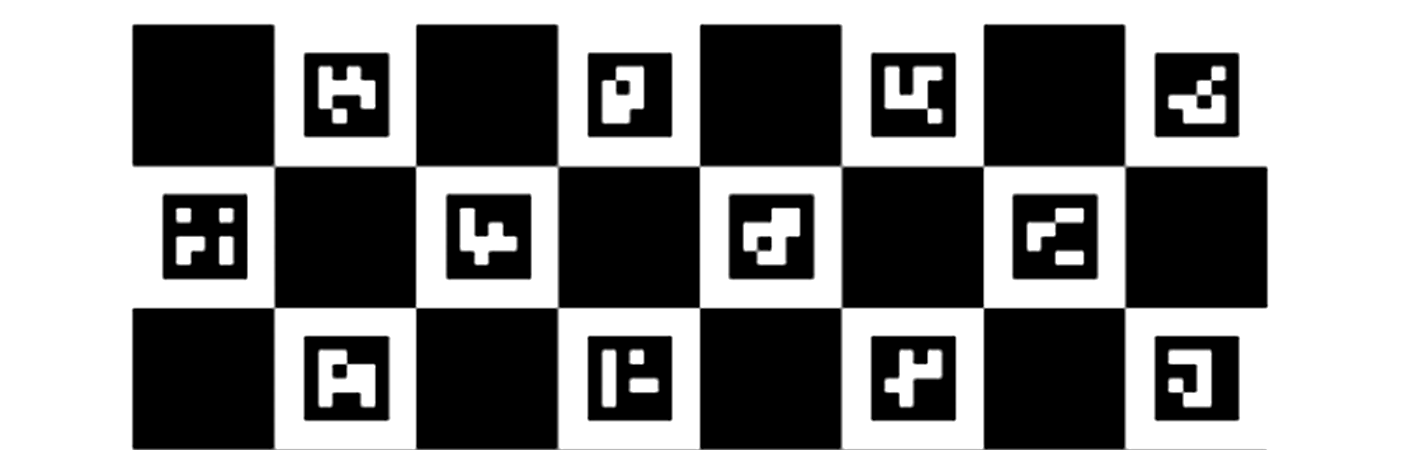

3. CharuCo Hedefleri

Şahmat tahtası köşeleri ile ArUco işaretleyicilerini birleştiren hibrit bir desen.

Algılama İş Akışı:

ArUco işaretleyicilerini tanımla → İşaretleyiciler arasındaki interpolasyonla yerleştirilmiş eyer noktalarını belirle.

Avantajlar:

Kısmi Görünürlük Desteği: Benzersiz işaretleyici kodlaması, kapalı veya kenarlarından kırpılmış hedeflerle kalibrasyon yapılmasına olanak sağlar.

Işıklandırmaya Karşı Dayanıklılık: Düzgün olmayan aydınlatmadan (örneğin, speküler yansımalardan) kaynaklanan hatalara direnç gösterir.

Alt piksel Düzeltme: Şahmat tahtasıyla elde edilen eyer noktası doğruluğuna eşdeğer doğruluk sağlar.

Sınırlamalar:

Algoritma Karmaşıklığı: Özel kütüphaneler gerektirir (OpenCV 3.0+).

İşaretleyici Yerleştirme: Kötü basılmış işaretleyiciler, tespiti bozar.

En İyisi: Çoklu kamera sistemleri, yüksek distorsiyonlu lensler ve dar alanlar.

III. Uygulama En İyi Uygulamaları

1. Baskı kalitesi:

Lazer basımlı veya kazınmış hedefleri, yansıtıcı olmayan yüzeylerde kullanın.

Düzgünlüğe dikkat edin (deformasyon toleransı: <0,1 mm/m²).

2. Görüntü Alma Protokolü:

Hedefi farklı yönelimlerde tutarak 15–30 görüntü alın (görüş alanının köşelerini kapsayın).

Işık ve odaklamayı tutarlı tutun.

3. Kütüphaneye Özel Notlar:

OpenCV: Şahmat tahtaları tamamen görünür olmalıdır; CharuCo için aruco modülü gereklidir.

Halcon: Dairesel ızgaralar için optimize edilmiş ve yerleşik asimetri işleme özelliğine sahip.

Kalibrasyon hedefi seçimi, hassasiyet gereksinimleri, çevre kısıtlamaları ve algoritmik destek arasında denge kurar. Kontrollü koşullar altında maksimum doğruluk sağlarken, şahmat tahtası desenleri, endüstriyel uygulamalar için eşsiz bir dayanıklılık sunar. Dairesel ızgaralar, stereo düzenlemeler için pratik bir denge sağlar. Hedef özelliklerini görüş sisteminizin ihtiyaçları ile uyumlandırarak, metrolojik olarak geçerli ölçümler için sağlam bir temel oluşturursunuz—bu da güvenilir makine görüşünün temel taşıdır.