Máy ảnh Thị giác Máy tính: Phối hợp Tốc độ Khung hình với Tốc độ Dây chuyền Sản xuất để có Hiệu suất Tối ưu

Máy ảnh Thị giác Máy tính: Phối hợp Tốc độ Khung hình với Tốc độ Dây chuyền Sản xuất để có Hiệu suất Tối ưu

Hiệu suất chính xác bắt đầu từ việc căn chỉnh tốc độ khung hình

Tại sao sự không khớp tốc độ khung hình gây ra mất hiệu quả công nghiệp

Khi các dây chuyền đóng chai vượt quá 1.200 đơn vị/phút, các camera chụp ít hơn 800 khung hình mỗi giây có thể bỏ qua các khuyết tật quan trọng như nắp bị lệch hoặc nước tràn. Thách thức tương tự có thể xảy ra trong bao bì viên nang dược phẩm khi tốc độ khung hình không ổn định dẫn đến khoảng trống kiểm tra. Một nhà sản xuất sữa toàn cầu được báo cáo đã giảm rò rỉ chất thải bằng phần trăm hai chữ số sau khi tái hiệu chuẩn hệ thống thị giác theo tốc độ băng chuyền của họ.

Phương trình cơ bản vẫn không thể thỏa hiệp:

FPS tối thiểu ≥ (Tốc độ Dây Chuyền × Hệ Số Chính Xác) ÷ 60 Các yếu tố chính xác khác nhau—điện tử yêu cầu 300+ trong khi các dây chuyền đóng gói có thể dừng ở gần 120.

Điều chỉnh tốc độ khung hình phù hợp với đặc trưng sản xuất của bạn

Quy trình công nghiệp được chia thành hai kiểu chuyển động cơ bản:

Hệ thống Dòng Chảy Liên Tục (ví dụ, lắp ráp dựa trên băng chuyền) Tốc độ khung hình phải tương ứng số pixel bao phủ mỗi sản phẩm với tốc độ của dây chuyền. Cảm biến thị giác HIFLY có thể điều chỉnh phơi sáng động trong quá trình điền container khi việc hình thành bọt đòi hỏi sự điều chỉnh ở mức microgiây.

Hệ thống Chuyển Động Gián Đoạn (ví dụ, hàn robot) Các nhà sản xuất ô tô sử dụng việc chuyển đổi tốc độ khung hình thích ứng đã quan sát thấy ít từ chối sai hơn trong các giai đoạn tăng tốc của tay robot. Đồng bộ hóa máy ảnh với mã hóa viên quay cho phép chuyển đổi giữa 50fps (trạng thái ổn định) và 150fps (chuyển động nhanh).

Tối Ưu Tốc Độ Khung Hình Trong Các Lĩnh Vực Quan Trọng

▶ Đóng chai và chất lỏng Việc đóng chai tốc độ cao với hơn 600 container/phút đòi hỏi 800–1.000fps với cảm biến màn trập toàn cầu. Một nhà sản xuất chai đã giảm 23% tỷ lệ loại bỏ sai do bọt bằng cách sử dụng camera HIFLY kết hợp màn trập 1/100.000s với đèn LED pulsed. Các hiện tượng văng chất lỏng có thể được giảm thiểu thông qua sự đồng bộ hóa này.

▶ Kiểm tra linh kiện ô tô Việc kiểm tra mối hàn bị ảnh hưởng khi có sự thay đổi trong quỹ đạo robot. Việc áp dụng điều chỉnh tốc độ khung hình theo tín hiệu encoder đã giúp một nhà sản xuất hộp số ở châu Âu giảm 37% các dấu hiệu không đúng vị trí. Các giao thức quản lý nhiệt của HIFLY được cho là duy trì tính nhất quán của khung hình trong 5% độ lệch trong quá trình vận hành 24/7.

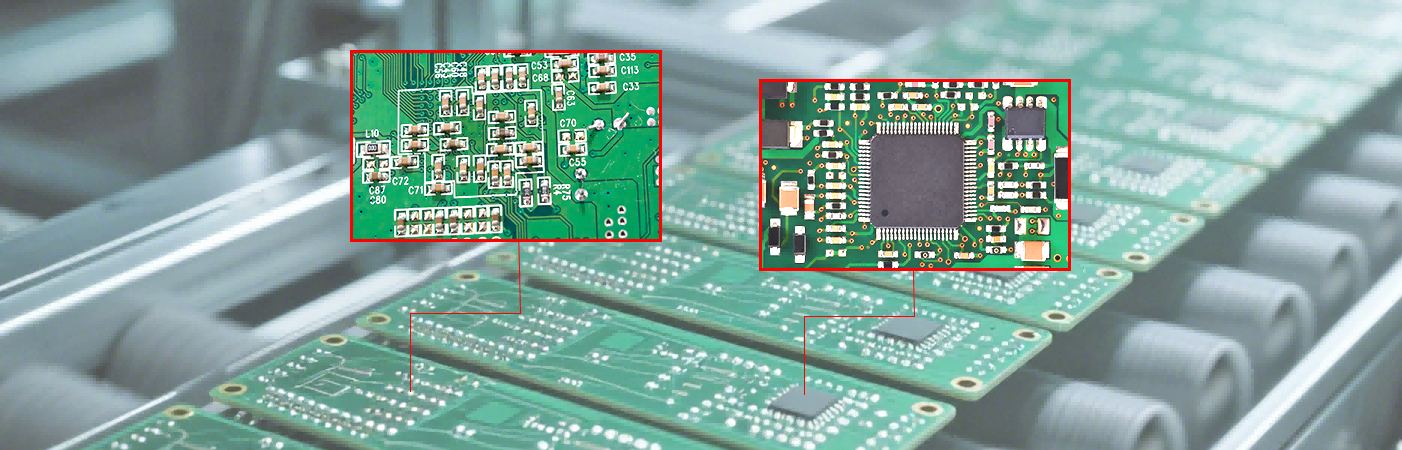

▶ Xác thực PCB Điện tử Kiểm tra các thành phần 0402 (0,4mm x 0,2mm) yêu cầu 180fps ở độ phân giải 1080p . Mặc dù 4K/45fps có vẻ hấp dẫn, việc cân đối độ phân giải/tốc độ khung hình có thể làm tăng chi phí hệ thống trên 30% mà không có lợi ích phát hiện khuyết tật. Quét ROI chọn lọc có thể cải thiện hiệu quả tại đây.

Chi phí Ẩn của Sự Không Đồng Bộ Tốc Độ Khung Hình

|

Yếu Tố Bị Bỏ Qua |

Tác động |

Giảm nhẹ |

|

Tốc độ truyền ổn định |

Khung hình giảm xuống còn 17% trong ca đêm tại các cơ sở dược phẩm do cảm biến quá nhiệt |

Máy ảnh có điều chỉnh nhiệt |

|

Tình trạng quá tải băng thông |

Kiểm tra rãnh lốp ở tốc độ 2.000fps tiêu thụ 83% dung lượng mạng |

Giao diện CoaXPress-12 hoặc sợi quang |

|

Việc quy định quá mức |

Của nhà máy đóng gói sự tận dụng thấp 40% của các hệ thống 1,000fps |

Điều chỉnh phù hợp xuống 250fps thông qua phân tích chuyển động |

Bộ công cụ thực hiện Tần số Khung hình của bạn

1. Ánh xạ Tham số

MarkDown

| Tốc độ Đường chuyền | Kích thước Khuyết tật | FPS Mục tiêu | |-----------------|-------------|------------| | >200 đơn vị/phút | <0.5mm | 150–400 | | >500 đơn vị/phút | <0.2mm | 500–1,000 |

2. Danh sách Kiểm tra Triển khai

- Xác minh 20% dung lượng dự phòng tần số khung hình cho các bản nâng cấp tốc độ trong tương lai

- Phù hợp thời gian chớp đèn đến FPS tối đa (ví dụ, ≤10μs cho 1,000fps)

- Đảm bảo độ rộng băng thông giao diện ≥ (Độ phân giải × FPS × 8)

3. Chiến lược Hiệu suất

- Kích hoạt theo vùng giảm 40% nhu cầu khung hình trong kiểm tra bảng hiển thị

- Mẫu lấy mẫu thích ứng với chuyển động trong hậu cần đã giải phóng 30% tài nguyên GPU

Khung Đồng bộ Hóa Thế Hệ Tiếp Theo

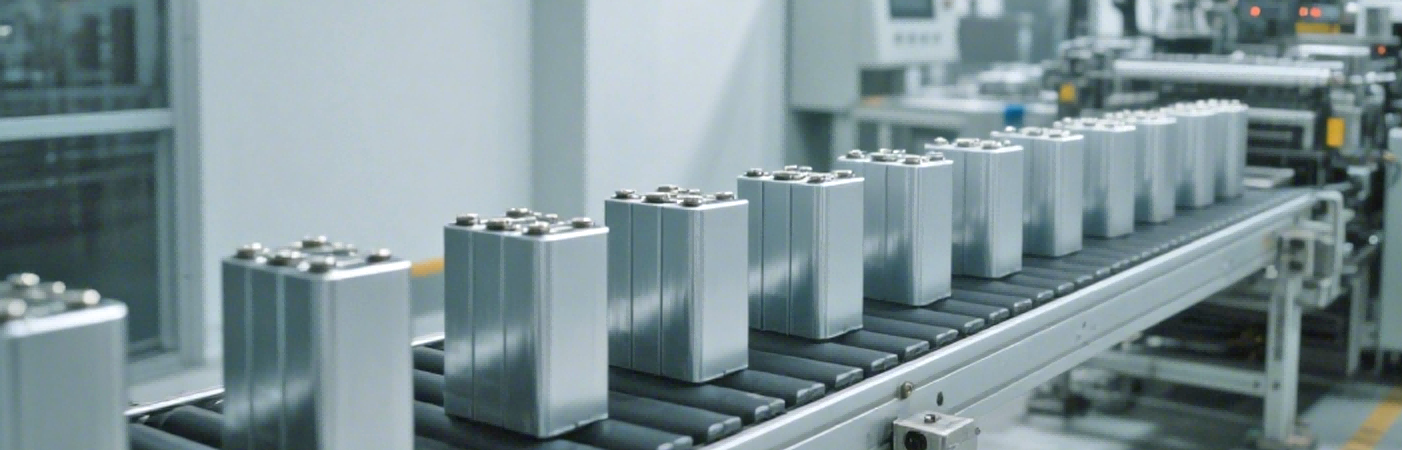

Bộ điều khiển thị giác được thúc đẩy bởi AI có thể điều chỉnh tốc độ khung hình theo thời gian thực dựa trên vận tốc của đối tượng—một nhà máy pin đã tận dụng điều này để nâng cao OEE lên 9.2% . Các ô sản xuất đa camera hiện nay đồng bộ hóa thời gian phơi sáng trong phạm vi μs , tăng cường năng suất trên 30% trong lắp ráp hộp số.

Các chỉ thị máy móc EU sắp tới có thể bắt buộc nhật ký kiểm toán tốc độ khung hình , khiến việc tài liệu hóa hiệu suất bền vững trở nên thiết yếu. Hệ thống HIFLY được báo cáo là nhúng thời gian đóng dấu cấp sản xuất để sẵn sàng tuân thủ.

Các yếu tố cần xem xét khi chọn đối tác triển khai

Khi đánh giá các nhà cung cấp giải pháp thị giác:

- Xác nhận tính ổn định khung lâu dài (>97,5% tại tải trọng đỉnh)

- Tìm kiếm khả năng tùy biến linh hoạt - một số nhà cung cấp có thể cung cấp giải pháp cụ thể cho ứng dụng trong vòng 3 tuần

- Mô hình chi phí tổng cộng trong suốt chu kỳ sống bao gồm bảo trì và thời gian ngừng hoạt động.