What Is the Speed of Machine Vision Inspection? Unlocking High Speed Precision

In today’s fast-moving industries, every second counts. That’s where machine vision inspection shines, delivering lightning-fast quality checks that keep production lines humming. But just how fast is machine vision inspection? Spoiler: it’s often faster than the blink of an eye. From spotting defects on a conveyor belt to verifying labels in a flash, this technology is redefining efficiency in manufacturing, food processing, and beyond.

In this post, we’ll break down what drives the speed of machine vision inspection, explore real-world examples, and show why it’s a game-changer for businesses. Whether you’re curious about automation or looking to optimize your workflow, let’s zoom in on the speed that’s transforming industries!

What Is Machine Vision Inspection?

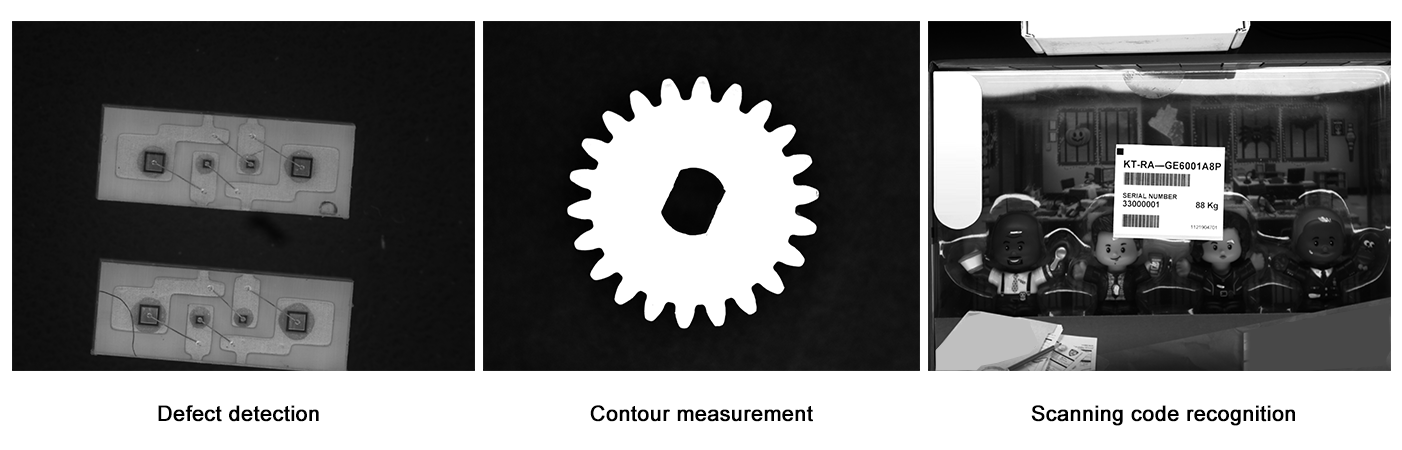

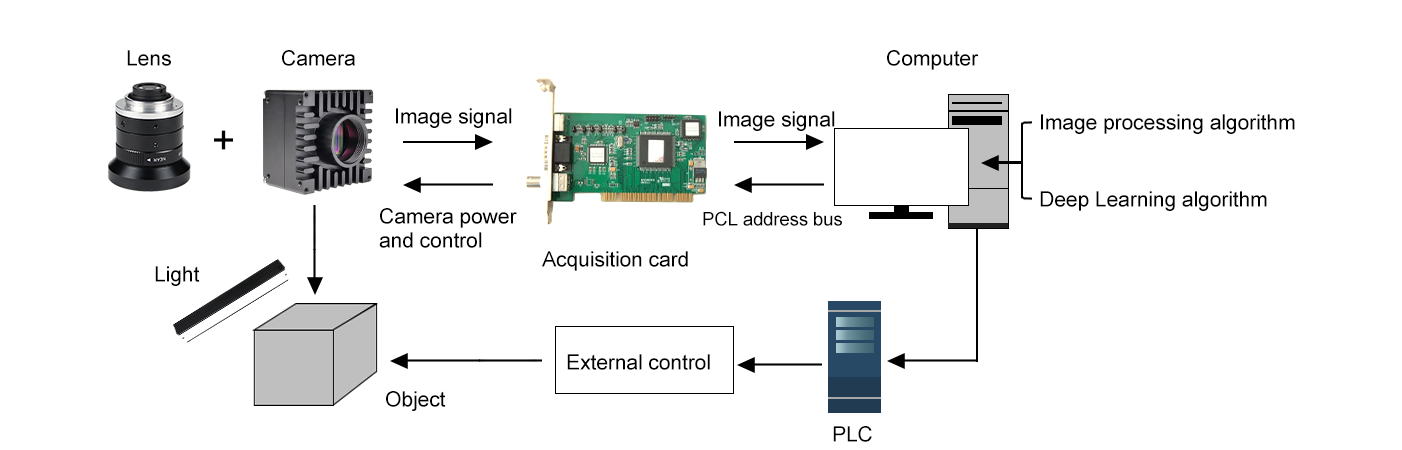

Machine vision inspection uses cameras, sensors, and software to analyze images and make decisions—think of it as a super-smart set of eyes that never tire. These systems scan products for defects, measure dimensions, or verify details like barcodes, all without human intervention. Speed is their superpower, enabling them to keep pace with high-throughput production lines while maintaining pinpoint accuracy.

But what exactly determines how fast these inspections happen? Let’s unpack the factors that make machine vision a speed demon.

How Fast Is Machine Vision Inspection?

The speed of machine vision inspection varies by setup, but it’s often measured in milliseconds or even microseconds. For context, a typical system can process thousands of parts per minute—sometimes inspecting an item in as little as 10-50 milliseconds (that’s 0.01 to 0.05 seconds!). In high-speed scenarios, like scanning bottles on a filling line, advanced systems can hit rates of 100,000 inspections per hour or more.

So, what’s behind this blistering pace? It comes down to a few key components working in harmony.

Factors Driving Inspection Speed

1. Camera Technology

Line-Scan vs. Area-Scan: Line-scan cameras, which capture images one line at a time, are blazing fast for continuous motion (e.g., inspecting a moving web of paper). Area-scan cameras snap full frames and are quick for static or slower-moving objects.

Frame Rates: High-end cameras boast frame rates of 1,000+ frames per second, capturing rapid sequences for real-time analysis.

2. Processing Power

Powerful CPUs or GPUs crunch image data instantly. Modern systems leverage AI algorithms to analyze complex patterns in a fraction of a second, cutting down decision time.

3. Lighting and Optics

Bright, focused lighting (like LED strobes) ensures clear images, reducing the need for multiple scans. High-quality lenses sharpen details, speeding up analysis.

4. Software Optimization

Streamlined algorithms prioritize critical data, skipping redundant pixels to boost speed. Real-time processing means decisions happen as images are captured.

5. Production Line Integration

Synchronized triggers—like encoders tied to conveyor speed—ensure cameras snap at the perfect moment, keeping inspections seamless even at high velocities.

Real-World Speed Examples

To give you a sense of what’s possible:

Electronics: A machine vision system inspects solder joints on circuit boards at 500 parts per minute, catching defects in under 100 milliseconds per board.

Food Packaging: Cameras verify labels on 1,200 bottles per minute, with each inspection taking ~50 milliseconds.

Automotive: Surface scans of car panels for scratches happen at 10 meters per second, with real-time flaw detection.

These speeds aren’t just impressive—they’re critical for industries where delays mean lost revenue.

Why Speed Matters

Boosts Throughput: Faster inspections mean more products checked without slowing the line, maximizing output.

Reduces Costs: High-speed systems catch defects early, cutting waste and rework.

Ensures Quality: Speed doesn’t sacrifice accuracy—machine vision delivers consistent results, even at scale.

Scales with Demand: As production ramps up, fast systems adapt without missing a beat.

Challenges to Watch For

While machine vision is fast, it’s not magic. Here are a few hurdles that can affect speed:

Complex Inspections: Tasks like analyzing intricate patterns may slow processing if algorithms aren’t optimized.

Lighting Issues: Poor illumination can force multiple scans, dragging down speed.

Hardware Limits: Older systems or underpowered processors might struggle with high-speed demands.

The good news? Modern solutions—like AI-driven software and high-frame-rate cameras—are built to overcome these challenges.

How to Maximize Inspection Speed

Choose the Right Camera: Match line-scan or area-scan to your line’s motion profile.

Optimize Lighting: Use high-intensity, uniform light to capture clear images in one go.

Upgrade Processing: Invest in GPUs or edge computing for faster data crunching.

Streamline Software: Work with vendors to tailor algorithms to your specific needs.

Test and Tweak: Run trials to fine-tune timing and integration for peak performance.

The Future of Fast Inspection

As technology evolves, machine vision is getting even quicker. Advances in AI, 5G connectivity, and ultra-high-resolution sensors are pushing speeds to new heights. Soon, inspections that take milliseconds today could drop to microseconds, opening doors to applications we can’t yet imagine.

Ready to Accelerate Your Line?

The speed of machine vision inspection isn’t just a tech spec—it’s a competitive edge that drives efficiency and quality. Curious how it can transform your operation? Explore our cutting-edge machine vision solutions or connect with HIFLY experts for a customized demo. Don’t let slow inspections hold you back!