Camera-Lens Compatibility in Machine Vision Systems: Key Considerations for Seamless Integration

Optimizing Machine Vision Performance: Critical Camera-Lens Compatibility Factors

Seamless integration between industrial cameras and lenses could determine the success or failure of automated inspection systems. Ensuring physical, optical, and functional compatibility eliminates costly recalibration cycles and maximizes production uptime.

Navigating Physical Interface Compatibility

Industrial vision systems demand precise mechanical harmony between components. Three primary interface standards dominate the landscape:

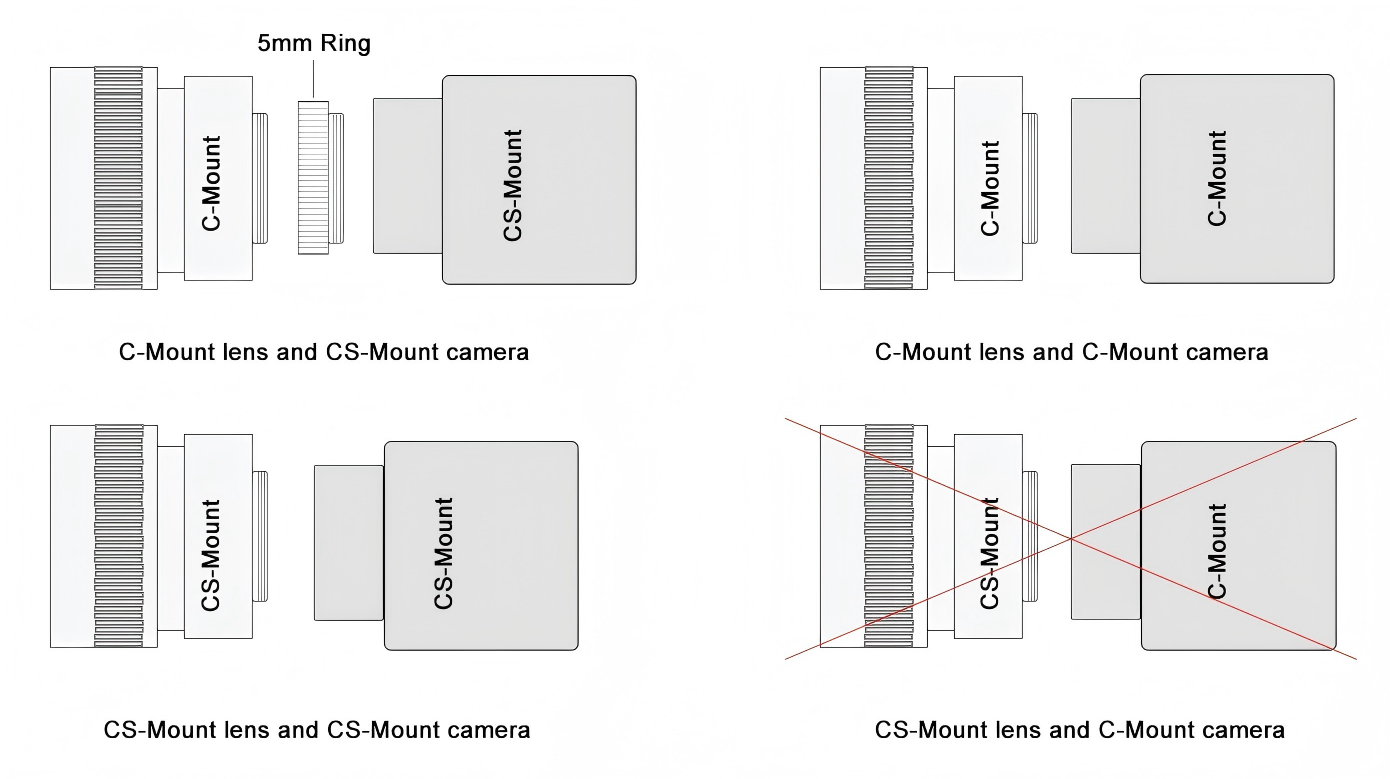

- C-Mount: Widely adopted for general-purpose applications, though confusion with CS-Mount could result in back focal distance errors. Verifying flange depth specifications prevents image softness.

- F-Mount: Favored for high-resolution inspections requiring larger sensors, yet thermal expansion may impact stability in uncontrolled environments.

- S-Mount: Essential for space-constrained setups like medical endoscopes, where vibration resistance becomes non-negotiable.

Mismatched mounts often lead to mechanical stress, sensor collisions, or inconsistent focus. Certain manufacturers provide hybrid locking rings accommodating tolerance variations – a solution worth exploring for high-vibration assembly lines.

Conquering Environmental Integration Challenges

Machine vision deployments frequently encounter extreme operational stressors:

- Thermal Dynamics: Lens housings could expand/contract across -30°C to 85°C ranges, altering focus positions. Thermally stable alloys maintain flange focal distances.

- Mechanical Stress: High-speed bottling lines (500+ fps) require sub-XXg lens weights to prevent robotic arm oscillation.

- Contaminant Exposure: Sealed IP67+ optical paths withstand coolant sprays in CNC machining cells.

Operational reliability may depend on validating compatibility through vibration simulations and thermal cycle testing – steps often overlooked during procurement.

Future-Proofing Your Vision System

Forward-looking compatibility strategies include:

- Resolution Headroom: Selecting lenses resolving 20% beyond current sensors accommodates future upgrades.

- Protocol-Driven Pairing: Emerging electronic lens IDs automatically configure camera settings upon mounting.

- Modular Interfaces: Some optical designs feature swappable mounting adapters, easing transitions between C/CS/F-Mount cameras.

HIFLY’s Practical Integration Framework

Achieving seamless compatibility involves methodical verification:

Demand Mapping Convert application requirements (min. defect size, working distance, temperature swings) into optical/mechanical specs using parametric selection tools.

Validation Protocol

-

- Verify flange focal distance tolerances with interferometry reports

- Review thermal MTF stability datasets

- Confirm thread engagement depth compatibility

Lifecycle Analytics Compare requalification costs of partial upgrades versus full replacements. Industry experiences suggest up to 8:1 ROI from thorough upfront compatibility testing.

Conclusion: Compatibility as Strategic Advantage

Camera-lens compatibility transcends technical specification – it underpins system reliability, accuracy, and total cost of ownership. Partnering with manufacturers offering comprehensive compatibility data, environmental testing certifications, and modular optical architectures could significantly de-risk integration. As machine vision permeates increasingly complex production environments, mastering these synergies becomes indispensable.