LED Machine Vision Lighting Guide for Automated Systems

LED lighting is the backbone of reliable automated machine vision—its speed, stability, and spectral consistency directly dictate inspection accuracy in high-speed production. As a 15-year global provider of machine vision solutions, HIFLY Technology (Shenzhen) offers industrial-grade LED machine vision lighting (backed by ISO 9001:2015 certification) to clients across 30+ countries, aligning with the rigorous demands of automated systems. Below, we break down why LEDs are indispensable, core illumination techniques, and material-specific optimizations.

Why LED Lighting Is Essential for Reliable Machine Vision Light Performance

Physics of Light–Sensor Synchronization in High-Speed Automation

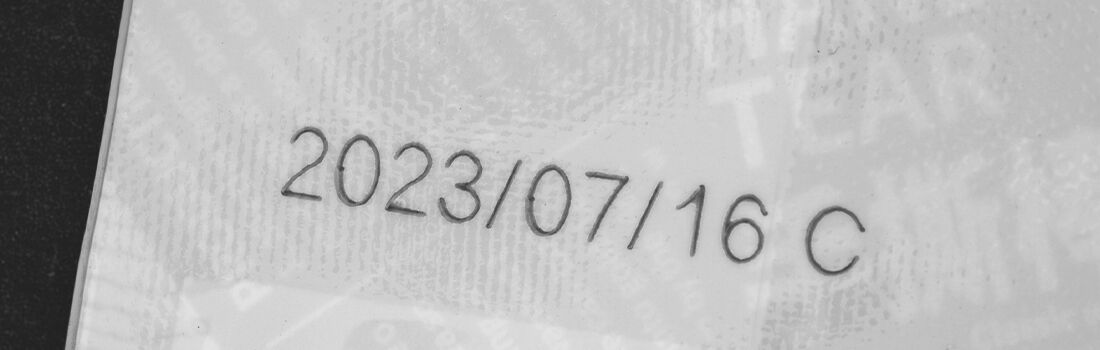

For high speed automation to work properly, the timing between light flashes and camera shutter needs to be spot on down to the microsecond level. LEDs can respond in just 10 microseconds or less, way better than old fashioned halogen or fluorescent lights, so there's no motion blur when checking products quickly. Imagine a conveyor belt moving at 5 meters per second. If the lighting is even a millisecond late, that creates a 5mm distortion in images, which could mean tiny electronic parts get classified wrong. The lighting has to stay steady without flickering to deliver the same amount of light to each picture frame. This matters a lot for optical character recognition systems that need to read labels on over 500 packages every minute. Semiconductor factories dealing with defects measured in nanometers rely on LED lighting that keeps intensity changes below 0.1%. These specs meet requirements from ISO 9022-18 standard and what most manufacturers consider good practice nowadays.

LED vs. Halogen vs. Fluorescent: Lifetime, Stability, and Spectral Consistency

Machine vision lighting is largely taken over by LEDs because they last longer, have better color control, and stay stable over time. Traditional halogen lights drop about 30% brightness after just 1,000 operating hours. Fluorescent tubes aren't much better either, their color temperature can change by as much as 300K each month. Industrial grade LEDs tell a different story though. These high quality units keep at least 95% of their original brightness even after working for over 50,000 hours straight. That kind of consistency matters a lot in applications where timing is everything, such as when inspecting pharmaceutical blister packs during production runs. What makes LEDs really stand out is their ability to emit very specific wavelengths of light. For instance, a good LED will produce 630nm red light with less than 2nm variation in wavelength. Compare this to halogen bulbs which spread their energy across a broad range of colors spanning around 40 nm. The tighter color focus from LEDs creates much clearer images when looking for tiny scratches on shiny metal surfaces. Manufacturers report seeing up to 20% fewer missed defects when switching from standard light sources to these specialized LEDs.

Core Illumination Techniques for Machine Vision Light Applications

Effective machine vision light setups directly determine inspection accuracy in automated systems. Selecting optimal techniques minimizes false rejects while maximizing defect detection across diverse materials and surface properties.

Backlighting and Bright Field: Optimizing Edge Detection by Surface Reflectivity

Backlighting works by putting light sources behind objects, creating those sharp contrast silhouettes that are really good for measuring dimensions and spotting holes. Then there's bright field technique which shines light at a shallow angle between about 10 to 30 degrees from the front side, making surface textures stand out more clearly. Combine both approaches and they take advantage of how materials reflect light differently, boosting edge detection accuracy on metal components around forty percent better than just using regular diffuse lighting. This combination cuts down on measurement mistakes during precision machining work and helps robots align parts correctly too.

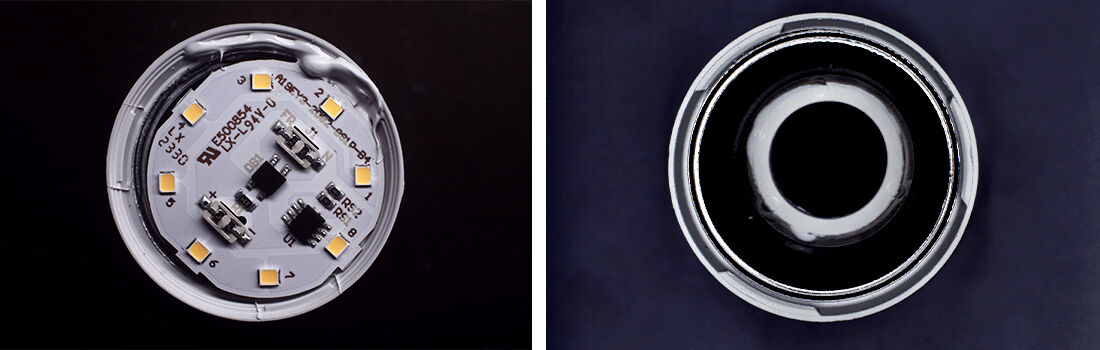

Dark Field and Coaxial Lighting: Detecting Micro-Scratches on Specular Surfaces

Dark field illumination works by bouncing light at angles below 30 degrees off of surface flaws, which makes those tiny scratches (less than 5 microns) visible when regular lighting just misses them entirely. With coaxial lighting, the light actually travels along the same path as the camera lens, so it cancels out those annoying reflections we see on shiny stuff like polished aluminum or glass with coatings. A study published last year in Optics Manufacturing showed something interesting too. When manufacturers combined both methods together, they spotted 32% more scratches on metal surfaces compared to before. Plus, there were fewer false alarms caused by glare. These techniques have become pretty standard now in industries where quality matters most, especially for checking car paint jobs and verifying electronic components where even the smallest defect can be a big problem down the line.

Structured Laser Lighting for 3D Profile Extraction in Robotic Guidance

When structured laser lighting shines those carefully measured line patterns on an object, what happens next is pretty amazing. The way these lines get distorted tells us exactly what shape something is, down to the millimeter level for 3D reconstructions. For robots trying to grab parts from bins, assemble components, or follow weld seams, this depth information means they can adjust their paths instantly as they work. Real world tests show these systems can repeat measurements within 0.1 mm even when dealing with complicated shapes. That kind of precision matters a lot in places like airplane manufacturing where parts need to fit perfectly, or in stacking battery cells where tiny misalignments add up fast. What makes structured light so good? Well, unlike regular 2D cameras that struggle when things aren't facing the right way, this technique works no matter how an object is positioned or where it sits in space.

Material-Specific Lighting Optimization for Machine Vision Light Accuracy

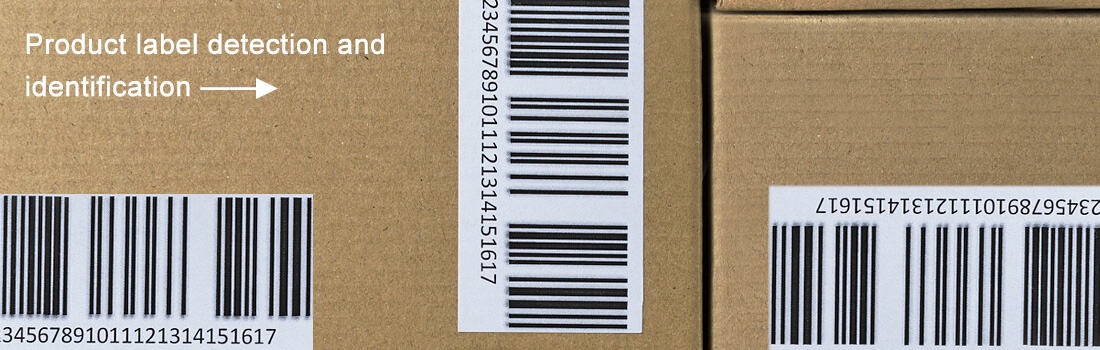

Diffuse Dome Lighting for Translucent Packaging OCR: Eliminating Specular Hotspots

Clear packaging like plastic bottles, frosted jars, and those little pill blister packs creates real problems for optical character recognition systems because of all the weird reflections that hide barcodes and labels. The answer? Diffuse dome lighting wraps around objects with even, all-around gentle illumination at just the right angle. These dome lights have a special curved shape inside that spreads out the light instead of letting it bounce back directly into cameras. What happens is pretty neat actually - the soft lighting makes those tiny raised letters or laser etchings stand out clearly without getting washed out. Some tests in the packaging world show these lights can improve reading success rates by about 40 percent over regular spotlights. On fast moving assembly lines where products are round or partly see-through, manufacturers keep coming back to these dome lights time after time when they need dependable results from their vision systems.

Ready to Enhance Your Automated System's Lighting?

LED lighting's speed, stability, and versatility make it irreplaceable for automated machine vision—but success depends on matching the right LED type and illumination technique to your application. For industrial-grade LED lighting solutions, or to pair lighting with complementary machine vision cameras (as offered by HIFLY), partner with a provider that understands the unique demands of automated systems.

HIFLY's 15 years of expertise in machine vision—spanning LEDs, cameras, and integrated solutions—ensures alignment with your production speed, defect size, and material needs. Contact us today for a no-obligation consultation to refine your lighting setup.