Application of Polarizers and Polarized Lights in Machine Vision Inspection Projects

Machine vision inspection is critical in intelligent manufacturing, but workpiece surface reflection, glare, and uneven illumination often degrade image quality and hinder accurate defect detection. Polarizers and polarized light sources, as key optical components, play a core role in regulating light polarization states—effectively suppressing unwanted reflections, enhancing defect contrast, and filtering ambient light interference. This significantly improves image clarity and detection reliability. Below is a focus on their core functions and concise practical application cases.

1. Core Functions of Polarization in Machine Vision

The primary role of polarization technology lies in optimizing the optical environment of machine vision systems through three key functions: First, suppressing specular reflection and glare: Filtering linearly polarized reflected light from smooth surfaces (e.g., metal, glass) to eliminate glare that obscures defects. Second, enhancing defect contrast: Converting subtle polarization state changes caused by internal defects (e.g., bubbles, cracks) in transparent materials into visible grayscale differences. Third, resisting ambient light interference: Blocking randomly polarized ambient light, ensuring stable image quality in complex industrial environments.

2. Concise Practical Application Cases

Polarization technology has been widely applied in solving challenging detection scenarios. Typical cases are as follows:

2.1 Automotive Glass Surface Defect Detection

Automotive glass has high transparency and smoothness, leading to strong specular reflection under ordinary lighting. By adopting linear polarized light sources and cross-polarization filtering (polarizer and analyzer at 90°), the reflection is effectively suppressed. Scratches, bubbles, and impurities on the glass surface are clearly displayed, with defect detection accuracy (≥0.1mm) reaching 99.5%—far exceeding the 85% of traditional systems.

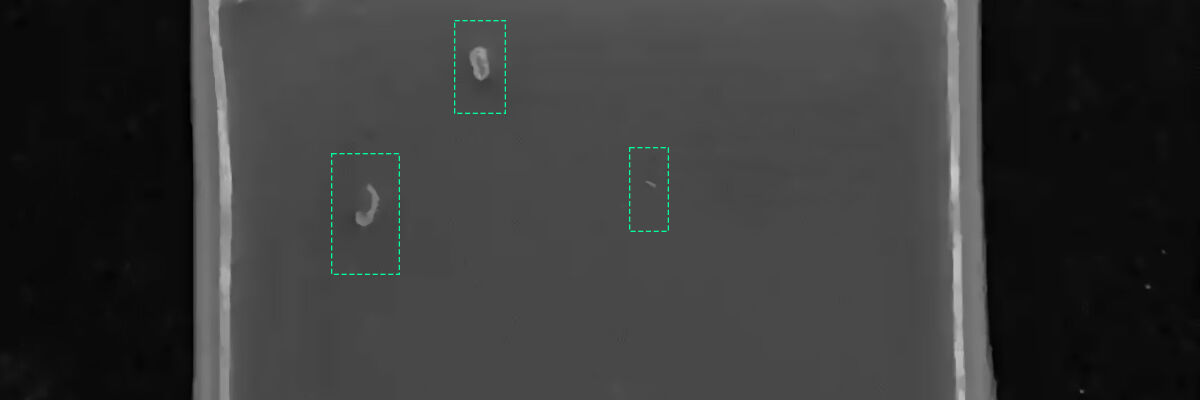

2.2 Plastic Film Internal Defect Detection

Transparent plastic films have subtle light intensity differences between internal bubbles/impurities and the substrate, making defects hard to identify. Polarized light induces birefringence at defects due to refractive index differences. Through polarization filtering, invisible internal defects are converted into obvious bright/dark spots, enabling accurate algorithm recognition.

2.3 Metal Engine Part Scratch Detection

Metal engine parts have mirror-like reflective surfaces, which blur scratch features under ordinary lighting. By adjusting the angle between the polarizer (in front of the light source) and the analyzer (in front of the camera), specular reflection is filtered out, while diffuse reflection from scratches is retained. Scratches appear as clear dark lines, ensuring accurate detection by vision algorithms.

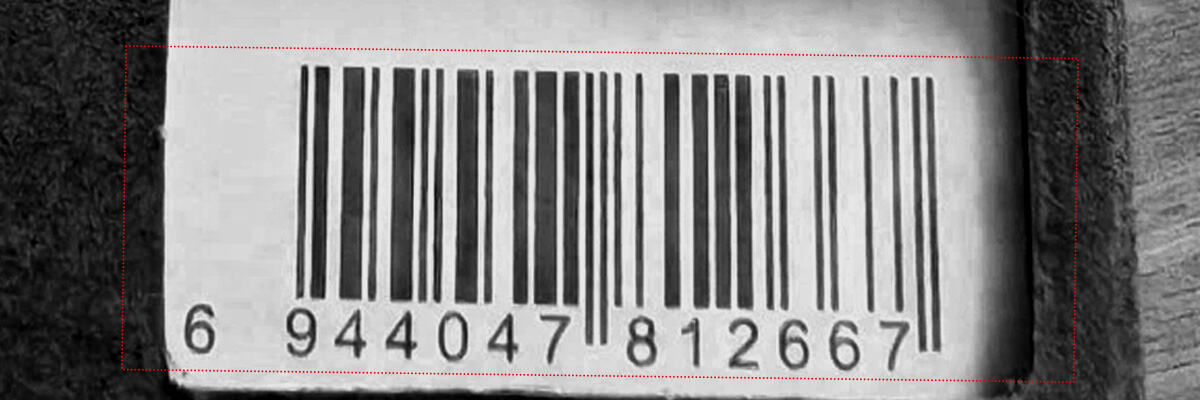

2.4 Aluminum Foil Packaging Barcode Recognition

Aluminum foil's high reflectivity makes printed barcodes unrecognizable under ordinary light. Polarization technology suppresses substrate reflection by filtering the polarized reflection light of aluminum foil, while retaining the scattered light from the barcode layer. This enables stable and accurate barcode recognition, ensuring product traceability.

3. Conclusion

Polarizers and polarized light sources play an irreplaceable role in machine vision by suppressing reflection, enhancing contrast, and resisting interference. Their application effectively solves detection difficulties in high-reflective, transparent, and complex surface workpieces. As intelligent manufacturing advances, polarization technology will further support high-precision and stable inspection in diverse industrial scenarios.