Machine Vision Light Types: How to Select the Best Illumination

Choosing the right machine vision light is a cornerstone of reliable inspection—poor illumination leads to missed defects, false rejects, and diminished ROI. As a 15-year global provider of machine vision solutions, HIFLY Technology (Shenzhen) offers a full range of industrial-grade illumination products backed by ISO 9001:2015 certification, serving clients across 30+ countries. Below, we break down core machine vision light types, critical selection criteria, and real-world applications to help you make informed choices.

Core Machine Vision Light Types and Their Optical Functions

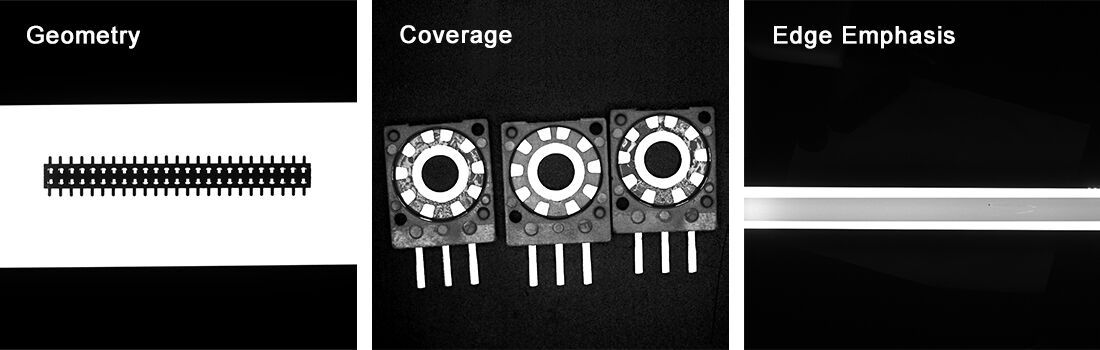

Bar, Ring, and Flat Lights: Geometry, Coverage, and Edge Emphasis

Bar lights give off focused light that works great when looking at straight line flaws and making edges stand out during inspection on conveyor belts. Ring lights go around lenses in circles to create even front lighting which cuts down on shadows for round objects and makes it easier to spot tiny parts. Flat panel lights spread light evenly across surfaces, so there's less glare on shiny electronic components and better chances of catching surface blemishes such as scratches. A recent study from optical engineers back in 2024 showed that using these special shaped lights actually increased how well we can see edges by about 28 percent over regular lighting conditions. This kind of improvement matters a lot in quality control settings where missing details can cost companies big time.

Backlight, Line, and Dome Lights: Solving Transparency, 3D Shape, and Specular Surfaces

When working with clear or semi-clear materials like glass vials, backlights help highlight what's inside. They make visible those tiny bubbles and differences in thickness that matter so much for quality control in drug manufacturing. Then there are these line generators that shoot out laser patterns across surfaces. What they do is basically map out three-dimensional shapes which helps technicians check weld seams and measure dimensions accurately. For shiny surfaces where reflections can be a problem, dome lights come into play. These special lights spread light from multiple angles creating even illumination without shadows. This makes all the difference when trying to spot microscopic scratches on polished metals or car body finishes that look great but might have hidden flaws. Some testing done at semiconductor factories actually found something interesting too. When using polarized dome lighting during inspections of mirror-like wafer surfaces, manufacturers saw about a 19 percent drop in false rejections. Not bad for improving efficiency while maintaining standards.

Critical Selection Criteria for Machine Vision Light Performance

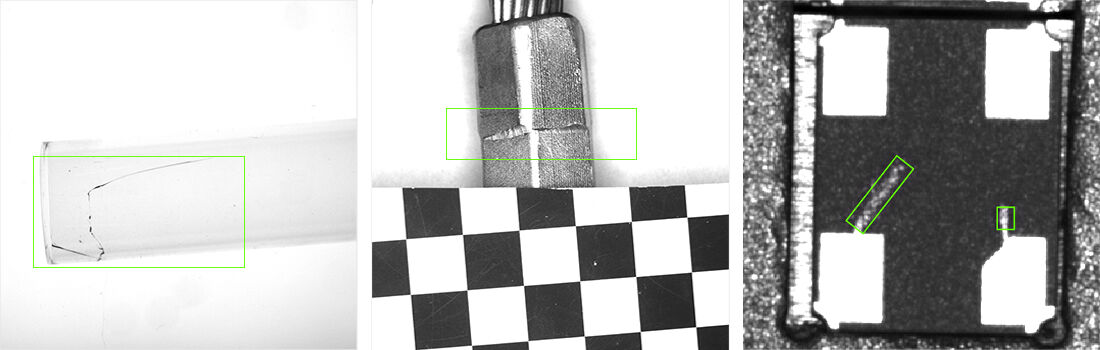

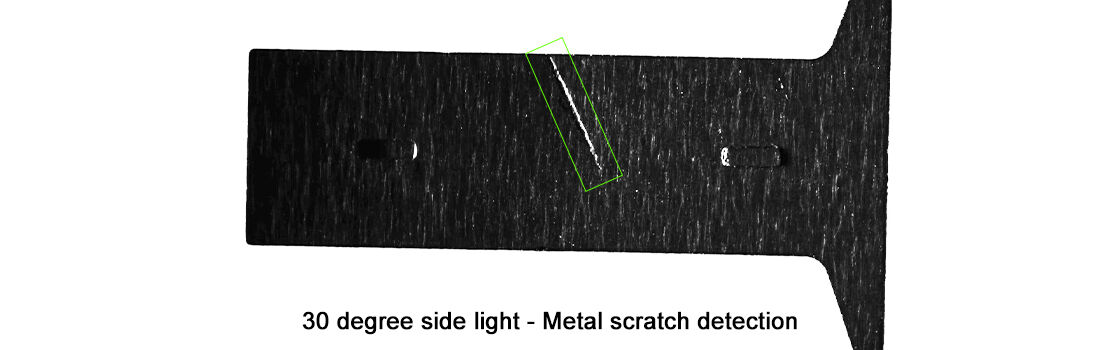

Angle, Position, and Diffusion: Controlling Contrast, Shadows, and Feature Visibility

How light hits something can make all the difference when it comes to seeing details clearly versus missing them completely. When we talk about front lighting, it actually makes those tiny blemishes stand out more on metal surfaces such as scratches. Side lighting angled around thirty to forty five degrees tends to highlight textures better too, which is why it works so well during PCB solder inspection processes. Diffusing light helps turn those annoying glare spots into useful information. Dome lights work wonders on those tricky curved car parts where bright spots would normally ruin everything, giving us about percent better measurements according to what most people in the field report. Putting lights in just the right spot cuts down on shadow problems that lead to incorrect rejections. For flat stuff, coaxial lighting does the trick pretty well. Backlighting creates these sharp outlines that help measure dimensions accurately. But get the diffusion wrong either way and suddenly we're spending extra time fixing issues from bad lighting conditions, sometimes wasting nearly a quarter of our total processing efforts.

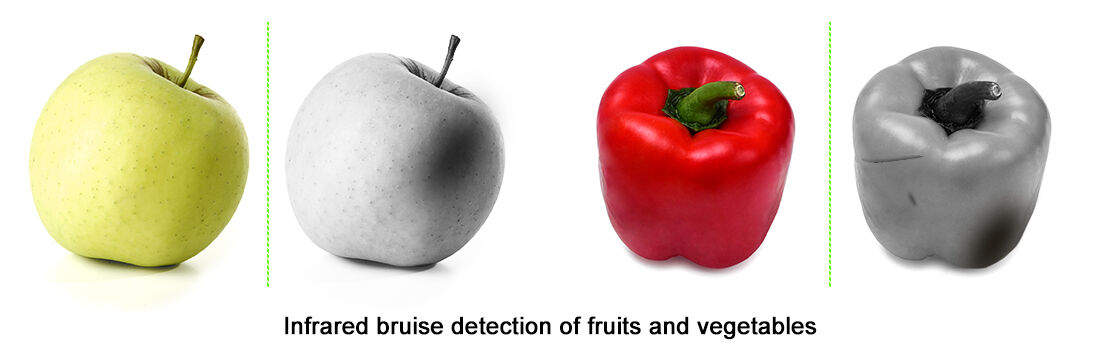

Wavelength Selection (UV–Visible–IR): Enhancing Material-Specific Contrast and Regulatory Compliance

How different materials react determines which wavelengths work best for inspection tasks. Take UV light at 365 nanometers for instance, it can spot those pesky contaminants like leftover adhesives on medical equipment. Meanwhile, infrared at around 850 nm gets through packaging layers so we can check what's inside food products without opening them up. When it comes to visible light colors, certain hues create better contrast against defects. Blue light at approximately 470 nm makes orange flaws stand out clearly on semiconductor wafers, improving our ability to catch problems compared to regular white lighting. Manufacturers need to follow IEC 62,471 safety guidelines regarding eye protection when working with IR light in their production lines. Farmers and packagers also benefit from near-infrared technology since it detects bruising in fruits and vegetables that nobody would notice with just their naked eye. Some materials are sensitive to heat though, especially various types of plastic films, so careful control over both UV and IR exposure becomes essential during quality checks to avoid damaging what we're trying to inspect.

How Lighting Directly Impacts Detection Accuracy and ROI

Quantifying Image Quality Gains: Contrast Ratio, SNR, and Defect Detection Lift

Optimal machine vision lighting improves foundational imaging metrics:

- Contrast ratio increases by 30–60% under directional lighting, making micro-cracks and fine surface anomalies stand out against backgrounds.

- Signal-to-noise ratio (SNR) improves by 15 dB with uniform illumination, reducing graininess in high-speed inspections.

- Defect detection lift reaches 40% in automotive part validation when combining backlights with multi-axis imaging. Higher contrast and SNR enable algorithms to identify sub-millimeter anomalies beyond human visual capability.

Cost of Poor Illumination: False Rejects, Rework, and System Downtime (AIA 2023 Data)

Inadequate lighting triggers cascading operational failures:

- False rejects rise 22% under inconsistent wavelengths, resulting in unnecessary scrapping of functional components.

- Rework costs consume 18% of production budgets when glare obscures weld seam defects.

- System downtime averages $15,000/hour during recalibration—often due to thermal drift in LED arrays (AIA 2023). Collectively, these errors erode ROI by 34% across 200 manufacturing sites studied. Proactive light optimization prevents an estimated $740,000/year in losses for high-volume electronics assembly.

Real-World Application Benchmarks: Matching Machine Vision Light to Industry Needs

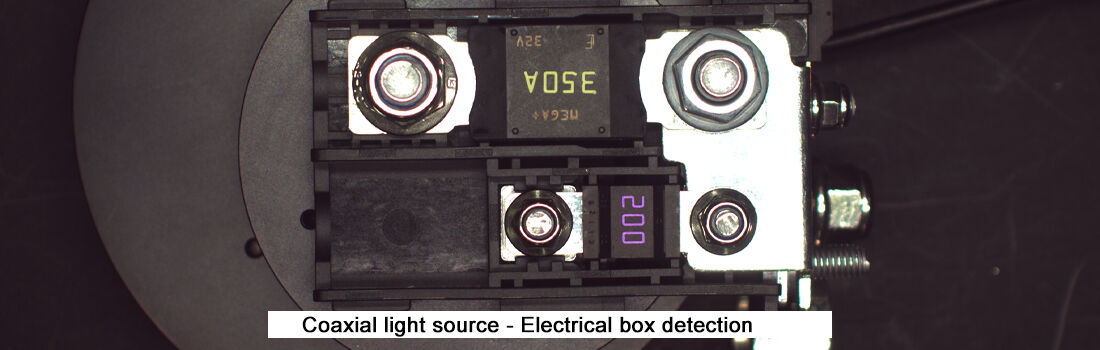

The real worth of optical setups becomes clear when looking at specific industry results where customized lighting solves unique inspection problems. Take automotive plants for example. Dome lighting helps get rid of those annoying reflections on curved parts so workers can check weld seams properly. Studies show this approach catches defects around 40% better than regular shop lights during quality checks. Over in electronics manufacturing, they use special coaxial lights emitting blue light at 470 nm wavelengths to spot tiny solder connections on circuit boards. This technique cuts down on false alarms by roughly 32%, as recent industry tests from last year confirmed. And don't forget food processing operations either. These facilities install industrial grade backlights rated IP69K with added UV features to find anything unwanted inside clear packages, all while keeping up with tough cleanliness requirements set by regulators.

When it comes to packaging verification systems, the return on investment becomes pretty clear when we look at how lighting is optimized. Directional bar lights really make a difference for optical character recognition (OCR) reading on tough surfaces such as crumpled labels or shiny metal foils. These specialized lights get a first pass read rate of around 99.7% in pharmaceutical serialization processes, compared to just 85 to 90% with regular lighting setups. Over in the textile manufacturing world, companies report seeing about 27% better inspection speeds thanks to those multi angle LED arrays that actually catch fabric weave problems that would otherwise go unnoticed under normal shop lighting conditions. Check out the numbers in the table below showing these improvements across different industries.

|

Industry |

Lighting Solution |

Key Metric Improvement |

Compliance Impact |

|

Automotive |

Dome + Diffused Array |

40% defect detection |

IATF 16949 alignment |

|

Electronics |

Coaxial + 470nm Blue |

32% false rejects |

IPC-A-610 validation |

|

Pharmaceuticals |

Directional Bar + IR |

99.7% read accuracy |

FDA 21 CFR Part 11 adherence |

|

Food Processing |

UV Backlight + Darkfield |

50% contaminant finds |

HACCP certification |

These benchmarks validate that structured light selection—not simply maximum brightness—delivers quantifiable accuracy improvements while addressing regulatory frameworks governing each vertical. The optimal machine vision light configuration emerges from measurable feature-enhancement requirements rather than generalized specifications, proving that application-tailored optics transform inspection reliability.

Ready to Optimize Your Machine Vision Lighting?

The right machine vision light transforms inspection from a cost center to a competitive advantage—success lies in aligning light type, angle, and wavelength with your material, task, and environment. For tailored guidance or access to industrial-grade illumination solutions (including wavelength-specific and ruggedized options), partner with a provider with proven industry experience.

HIFLY's 15 years of expertise in machine vision—from lights to cameras and integrated systems—ensures you get reliable, compliant solutions that maximize accuracy and ROI. Contact us today for a no-obligation consultation to refine your lighting setup.