A Brief Introduction and Application Scenarios of UV Cameras

Many people have heard of "infrared cameras," but what functions do their counterparts, "ultraviolet (UV) cameras," have?

In daily life, we often encounter problems that are "invisible to the naked eye"—trying to verify anti-counterfeit markings on food packaging but finding no obvious signs; needing to detect hidden cracks on circuit boards where ordinary cameras only see the surface; attempting to trace pipeline leaks where colorless gases are untraceable.

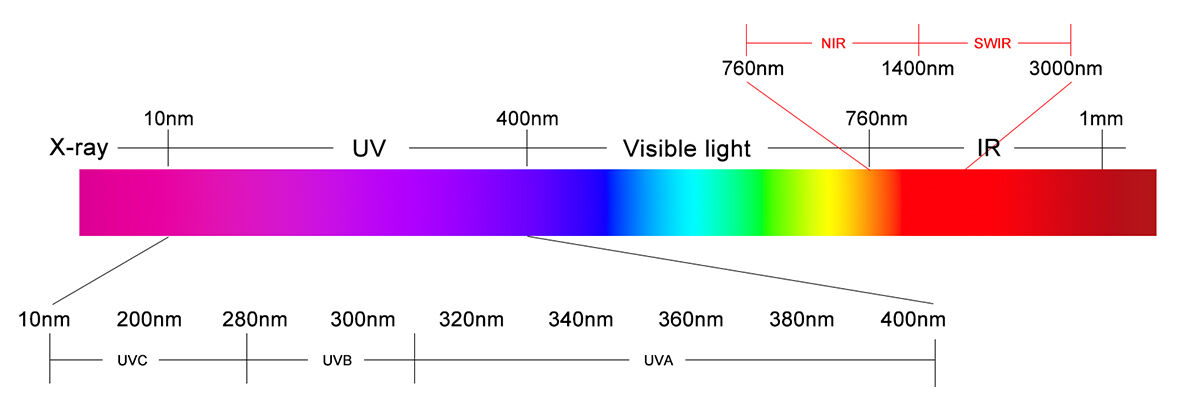

This is where UV cameras come into play. They can capture ultraviolet light (200nm-400nm) invisible to the human eye, converting "invisible signals" into clear images, becoming the "transparent eye" in fields like inspection, anti-counterfeiting, and security.

Today, we'll break down the core principles of UV cameras in simple terms, share three highly practical application scenarios, and include key points to avoid common pitfalls, helping you quickly grasp their value and usage.

I. Why Can UV Cameras "See Invisible Light"?

Many think "a UV camera is just a regular camera with a filter added." In reality, its core advantage lies in "capturing the special signals of ultraviolet light."

The light we see with our eyes is called "visible light" (400nm-760nm), while ultraviolet (UV) light is "invisible light" with a shorter wavelength. In nature, many substances produce a "fluorescence reaction" under UV light (e.g., anti-counterfeit marks on banknotes, organic pollutants), while others absorb or reflect UV light (e.g., uncured photoresist, leaking pipeline gases).

Ordinary cameras can only receive visible light and are "blind" to these UV signals. UV cameras, however, use specialized UV sensors (like back-illuminated sCMOS) and visible-light-blocking filters to accurately capture 200nm-400nm UV light, then convert these signals into grayscale or color images understandable to the human eye, revealing "invisible details."

Simply put: Ordinary cameras "can only capture what we can see," while UV cameras "can capture UV signals invisible to the naked eye." This is their core capability.

II. 3 Major Practical Application Scenarios for UV Cameras

The abilities of UV cameras—"fluorescence recognition," "hidden defect detection," and "colorless signal capture"—can solve practical problems across various fields. The following three scenarios are the most common and practical:

1. Scenario 1: Anti-Counterfeiting, Traceability & Quality Verification – Quickly Identifying "Invisible Marks"

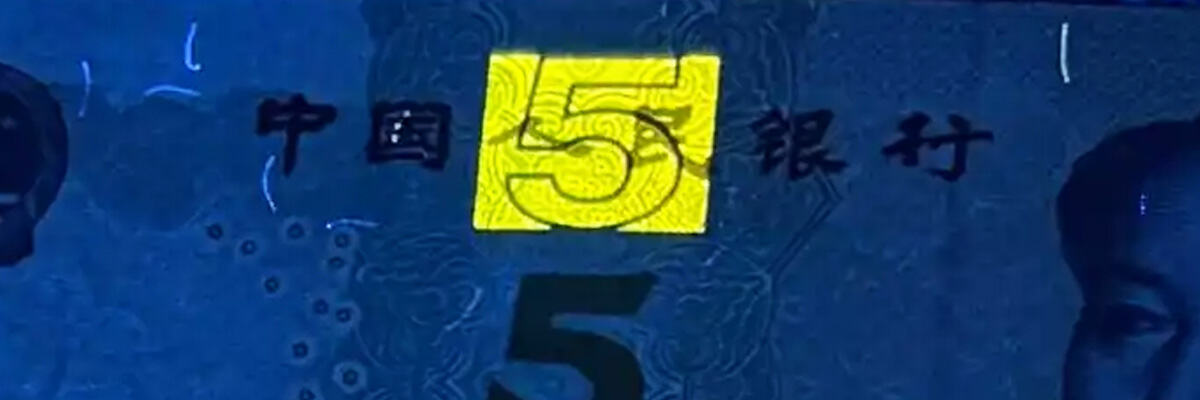

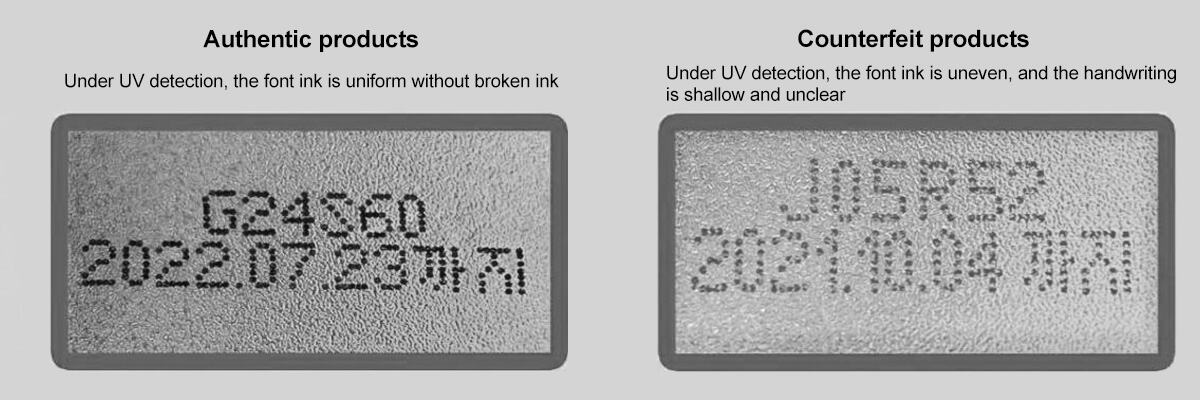

Core Need: Products like food, pharmaceuticals, tobacco, and alcohol often have "UV anti-counterfeit marks" (e.g., colorless fluorescent patterns, numbers) printed on their packaging to prevent forgery. These marks are invisible to the naked eye. Traditional manual inspection requires using a UV flashlight to illuminate each item individually, which is inefficient and prone to missed detection.

UV Camera Solution: Use a near-UV (UVA band, 320nm-400nm) camera paired with a UV light source (e.g., 365nm wavelength). Simply point it at the packaging to see the anti-counterfeit marks directly. It can also connect to a computer for automatic recognition, eliminating the need for manual scrutiny.

Example – Food Factory Packaging Inspection:

Pain Point: Manual inspection with a UV flashlight could only check 500 packages per hour. Eye fatigue led to a 15% missed detection rate and frequent misjudgments.

Result: Using a 2MP UV camera (365nm band) with an automated conveyor belt system, inspection speed reached 2000 packages per hour. Anti-counterfeit mark recognition accuracy hit 99.8%, and the missed detection rate dropped to 0.2%. The system also automatically logged the position of non-conforming products, eliminating the need for constant manual watch.

Suitable Scenarios: UV anti-counterfeit detection for food/pharmaceutical packaging, anti-counterfeiting and traceability for tobacco/alcohol/cosmetics, verification of fluorescent marks on documents (passports/ID cards).

2. Scenario 2: Industrial Defect Detection – Finding "Invisible Hidden Dangers"

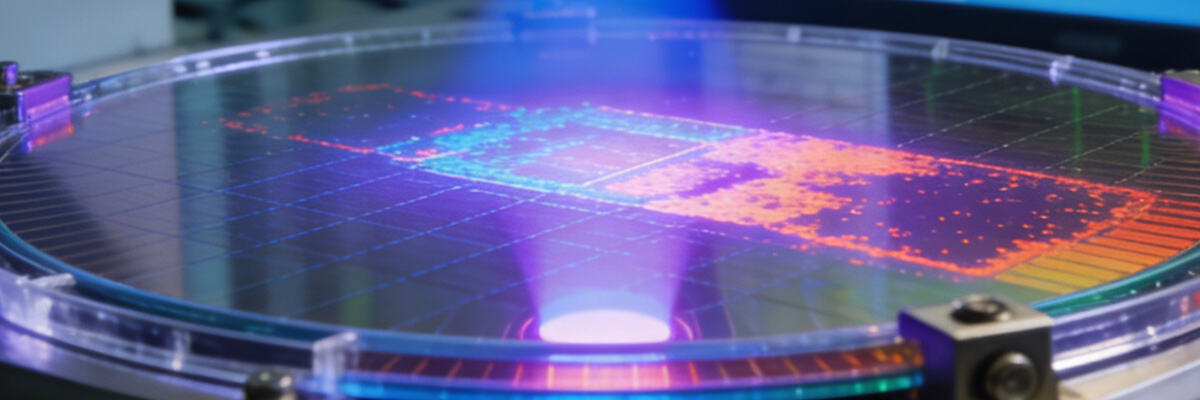

Core Need: In industrial production, many defects are invisible to ordinary cameras: e.g., organic contaminants on semiconductor wafer surfaces (at the 0.01μm level), micro-cracks on circuit boards, surface corrosion on metal parts. Missing these defects can lead to product failures, such as chip short-circuits or part breakage.

UV Camera Solution: Use a high-sensitivity deep-UV (UVC band, 200nm-280nm) camera paired with a deep-UV light source (e.g., 254nm wavelength). It utilizes the fluorescence reaction of contaminants or differences in UV reflection from defects to pinpoint problems accurately.

Example – Semiconductor Wafer Contamination Inspection:

Pain Point: Ordinary cameras couldn't see organic contaminants below 0.1μm. Problems were only discovered in later process stages, leading to over 10 wafers scrapped daily due to contamination, with losses exceeding ¥50,000. Manual microscopic inspection took 8 minutes per wafer, making it extremely inefficient.

Result: Using a 5MP deep-UV camera (254nm band) with a spot light source for scanning achieved a 99.7% detection rate for contaminants above 0.01μm. Inspection time per wafer was reduced to 40 seconds. Daily scrapped wafers decreased by 9, leading to annual cost savings of over ¥1.6 million.

Suitable Scenarios: Semiconductor wafer surface contamination detection, circuit board micro-crack identification, metal part surface corrosion/oil contamination排查, photoresist residue detection.

3. Scenario 3: Leak Detection & Security Monitoring – Tracking "Colorless Dangers"

Core Need: Gas leaks (e.g., refrigerants, flammable gases) and pipeline seepage in industrial settings are often colorless and odorless, making them undetectable to the naked eye. Accumulation can lead to explosions or poisoning. "Corona discharge" from high-voltage equipment (e.g., power lines, transformers) also emits UV signals invisible to ordinary cameras; prolonged discharge causes equipment aging.

UV Camera Solution: Use a mid-UV (UVB band, 280nm-320nm) camera. It can capture the UV signals from leaking gases or the light spots from corona discharge from a distance without contacting the equipment.

Example – Chemical Plant Pipeline Leak Detection:

Pain Point: Previously relied on manual point-by-point testing with a leak detector, taking 2 hours per pipeline with a 20% missed detection rate. A past refrigerant leak caused workshop shutdowns, resulting in losses over ¥200,000.

Result: Using a 2MP mid-UV camera (300nm band) with a telephoto lens, an operator could scan an entire pipeline from 10 meters away in just 5 minutes. Leak point identification accuracy reached 99.5%. The system could also record video of leak locations. For one year, no shutdowns occurred due to leaks.

Suitable Scenarios: Industrial gas (refrigerant, flammable gas) leak detection, high-voltage equipment corona discharge monitoring, hidden fire source location at fire scenes (e.g., smoldering wood).

III. 3 Key Points for UV Camera Selection and Operation

1. Choose the Right "Wavelength Band"; Don't Blindly Buy "Full-Spectrum":

For anti-counterfeiting or surface oil detection, choose near-UV (UVA, 320nm-400nm). It's cost-effective and doesn't require special light sources.

For wafer contamination or photoresist detection, choose deep-UV (UVC, 200nm-280nm). It offers high sensitivity, but pay attention to light source matching.

For gas leak or corona detection, choose mid-UV (UVB, 280nm-320nm). It has strong anti-interference capabilities, suitable for outdoor/industrial scenes.

*(While full-spectrum cameras cover all ranges, their price is over 3 times that of specialized models and is unnecessary for most applications. Don't waste money.)*

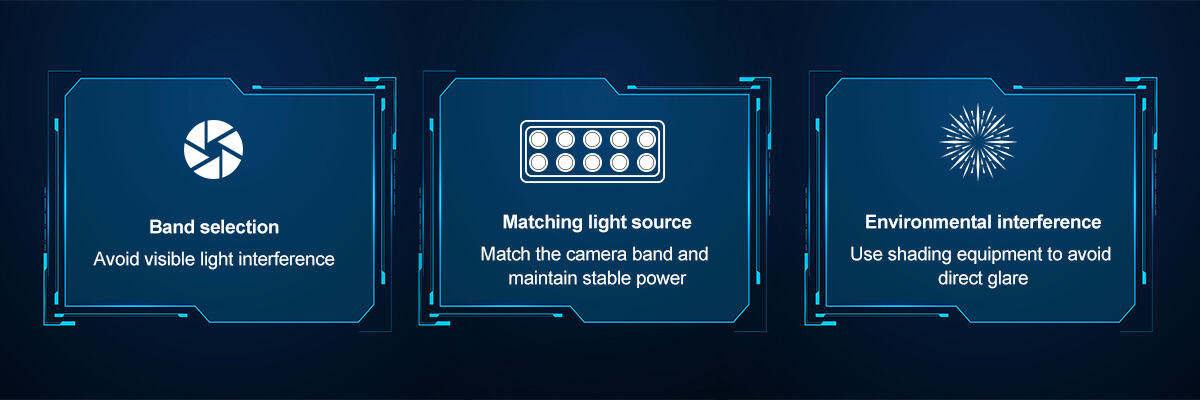

2. Light Source Must Be Matched, Otherwise Images Will Be Unclear:

UV cameras require specialized UV light sources (e.g., 365nm, 254nm). The light source wavelength must match the camera's band. For example, using a UVC camera with a UVA light source won't excite the fluorescence signals from contamination, resulting in a dark image. Additionally, for highly reflective objects (like metal), choose a diffuse light source to avoid reflection interference.

3. Mind Ambient Light; Don't Let Visible Light "Steal the Show":

UV signals are much weaker than visible light. If ambient light is too strong (e.g., direct sunlight, bright desk lamps), it can overwhelm the UV signal, resulting in blurry images. Therefore, for indoor inspection, use blackout curtains. For outdoor use, prefer cloudy days or nighttime, or add visible-light-blocking filters to the camera.

IV. Summary

The core value of UV cameras is helping us "see invisible signals that the naked eye and ordinary cameras cannot see"—from anti-counterfeiting to industrial inspection and safety monitoring. They solve many "invisible" problems while improving efficiency and reducing losses.

When selecting one, remember: First, clarify your goal (anti-counterfeiting/inspection/leak detection). Then, choose the corresponding wavelength band and light source. Avoid the pitfalls of "full-spectrum" and "unnecessary high megapixels," and you can use it to solve real-world problems.