Proč se strojové vidění stalo mainstreamem při průmyslové kontrole kvality?

Někdo mohou div, "Proč se strojové vidění stalo mainstreamem při průmyslové kontrole kvality?"

Tradiční ruční kontrola je často zatížena problémy: neschopnost detekovat drobné vady, neschopnost držet krok s vysokorychlostními výrobními linkami a stále rostoucí náklady. Naopak strojové vidění, které používá „stroje místo lidského oka“, se stalo novou mainstreamovou metodou průmyslové kontroly kvality.

I. Tři Hlavní bolestivé body tradiční kontroly, které vyžadují náhradu

1. Nízká přesnost

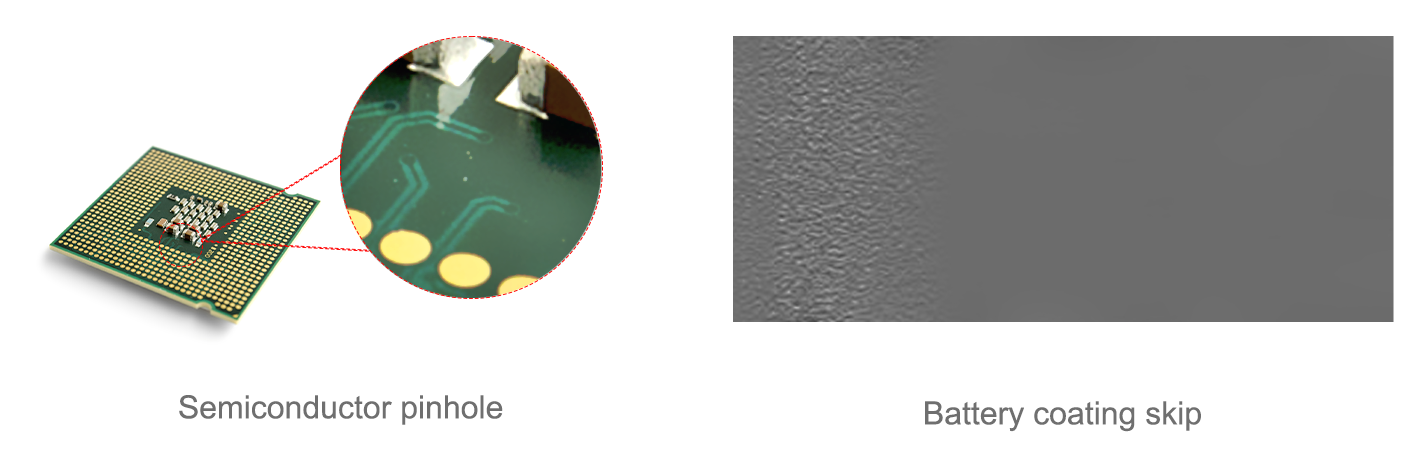

Lidské oko může rozlišit minimálně přibližně 0,1 mm. Jednoduše nevidí 1 μm malý otvor na polovodiči nebo 5 μm mezera v povlaku baterie a je náchylné k únavě (po 2 hodinách se míra chybných rozhodnutí zvýší z 5 % na 15 %).

2. Nízká efektivita

Lidské oko dokáže zkontrolovat 2 až 3 kusy za sekundu. U vysokorychlostních linek běžících rychlostí 3 m/s je možná pouze výběrová kontrola (10 %–20 %), což vede k vysokému riziku nepoznaných vad.

3. Vysoké náklady

Výcvik kvalitního inspektora trvá 3–6 měsíců, přičemž roční mzdy rostou o 8 % – 10 %. Ztráty způsobené návraty v důsledku nepoznaných vad jsou ještě vážnější (např. jedna automobilová společnost kdysi ztratila více než deset milionů kvůli chybám při kontrole).

II. Pět Klíčové výhody: Proč se strojové vidění stalo mainstreamovým

1. Přesnost nadcházející lidské oko: od milimetrů až po mikrony

(1) Výhoda: kamery s vysokým rozlišením + algoritmy dokážou detekovat vady 1–5 μm (o 20–100krát lépe než lidské oko), zachovávají přesnost 24/7 (míra chybných rozhodnutí < 0,5 %).

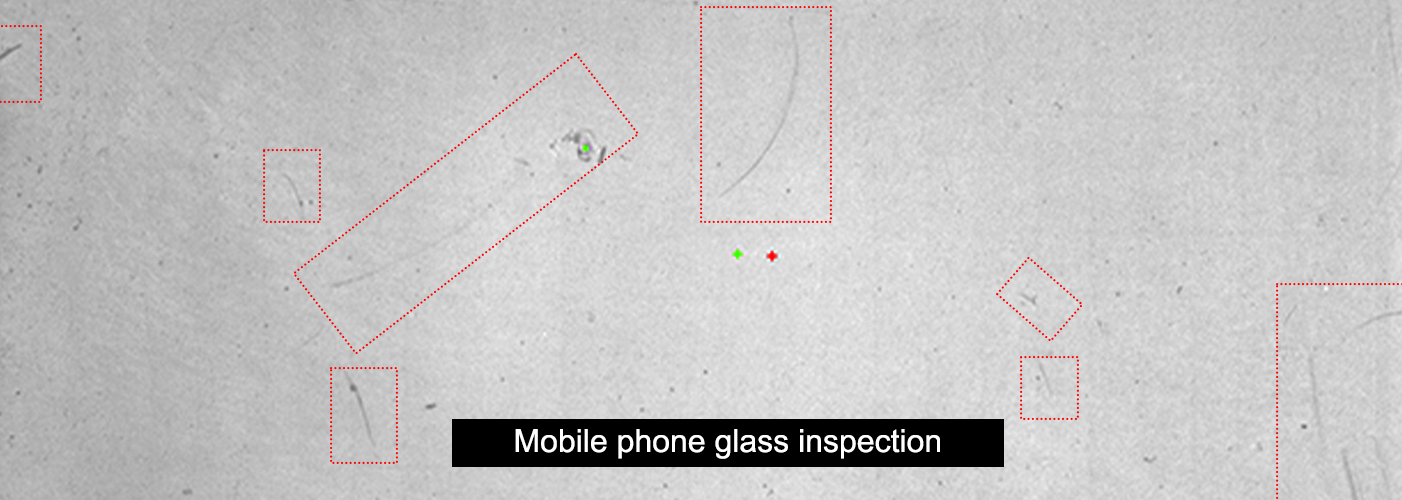

(2) Případová studie: kontrola polovodičových waferů detekuje pichlavé dírky velikosti 1 μm, čímž se snižuje míra nepoznaných vad z 8 % na 0,1 %. Kontrola skla mobilních telefonů nachází škrábance 0,5 μm, čímž se snižuje únik vadných výrobků o 90 %.

(3) vhodné pro: polovodiče, přesnou elektroniku, optické komponenty.

2. Rychlejší než ruční práce: od výběrové kontroly až po 100% plnou kontrolu

(1) Výhoda: Zpracovává 20–100 obrázků za sekundu, kompatibilní s vysokorychlostními linkami 1–5 m/s, umožňuje 100% plnou kontrolu (ruční metoda umožňuje pouze výběr vzorků).

(2) Případová studie: Na bateriové elektrodové lince o rychlosti 3 m/s systém strojového vidění zkontroluje 80 kusů za sekundu (ručně: 1 kus), dosahuje tak míry nepoznaných vad <0,2 % po plné kontrole a ročně snižuje počet vadných výrobků o více než 100 000 kusů.

(3) Uplatnění: Baterie pro obnovitelné zdroje energie, elektronické součástky, potravinářské balení.

3. Nižší náklady než ruční práce: Jednorázová investice, dlouhodobé úspory

(1) Výhoda: Jeden systém strojového vidění může nahradit 3–5 zaměstnance. Při průměrném ročním platu 100 000 ¥ na osobu činí doba návratnosti investice 1–2 roky. Navíc eliminuje potřebu školení a problémy spojené s odchodem zaměstnanců.

(2) Případová studie: Továrna na autodíly použila 2 systémy k nahrazení 6 pracovníků. Investice: 800 000 ¥, roční úspory: 600 000 ¥, návratnost za 14 měsíců a navíc snížení ztrát z opracování o 2 miliony ¥.

(3) Uplatnění: Výroba automobilů, potravinářské zpracování, kovové součástky.

4. Vydržte. Sledovatelnost údajů: Digitalizace celého procesu

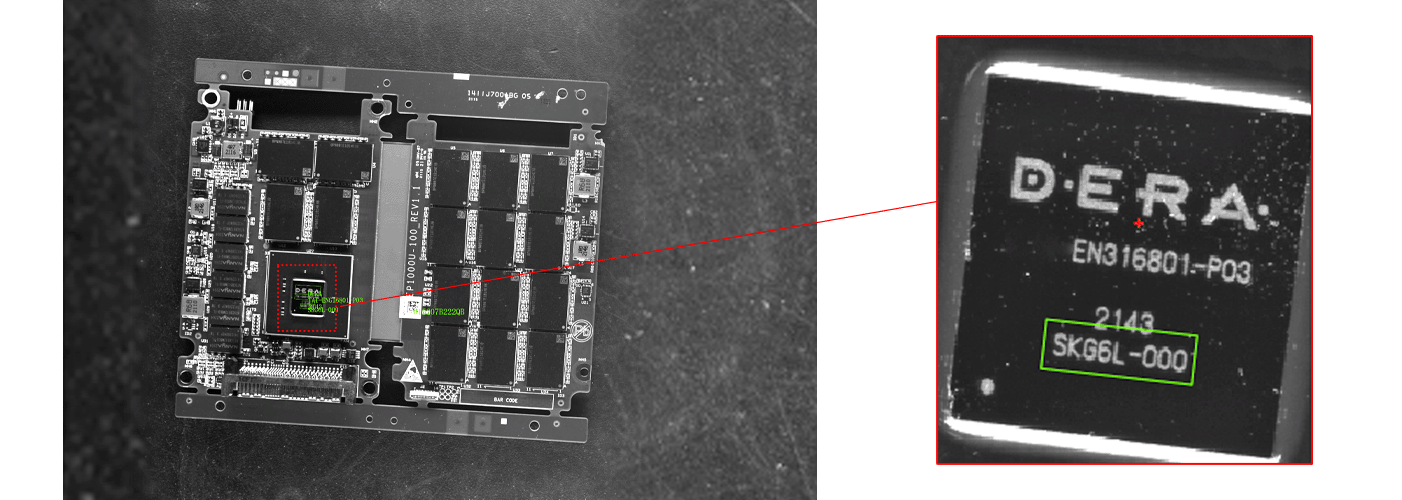

(1) Výhoda: Automaticky zaznamenává typ a umístění vad, synchronizuje se systémem MES/ERP, což umožňuje sledování vad v sérii až k zdroji (např. nesprávné parametry zařízení).

(2) Případová studie: Jedna továrna na PCB si všimla 10% nárůstu vad v šarži. Analýza údajů odhalila odchylku v parametrech expozičního stroje, která byla stanovena během 1 hodiny, čímž se zabránilo šrotu šarže.

(3) Vhodné pro: automobilový průmysl, elektroniku, zdravotnické zařízení.

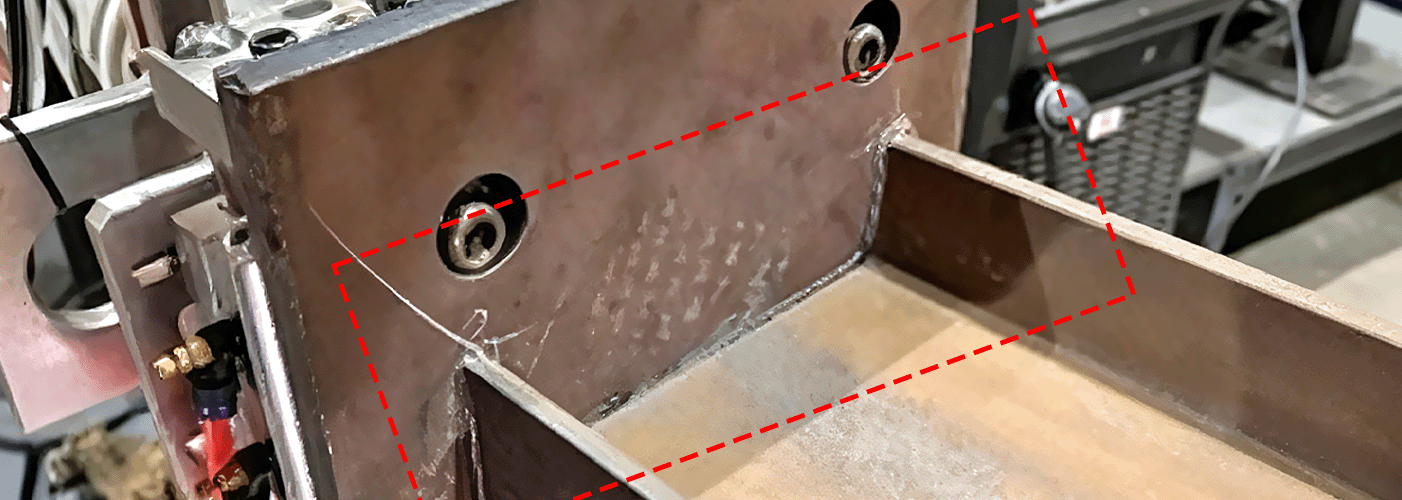

5. Vzdoruje drsnému prostředí: jde tam, kam lidé nemohou/nechtějí

(1) Výhody: odolnost vůči vysokým teplotám (-20 °C až 80 °C), ochrana proti prachu a vodě (IP65), odolnost vůči vibracím, používá se ve svařovnách, vysokotemperátorních vedeních.

(2) Případová studie: V závodě na svařování automobilů s teplotou 60°C a silným kouřem se vizuálně kontrolují úniky svařování 24 hodin denně a 7 dní v týdnu s přesností 99,5%. Zpracovatel ocelárny kontroluje ocelové desky, odolné proti prachu a vibracím, což zvyšuje účinnost 5x.

(3) Vhodné pro: svařování, malování, ocelářství, hutnictví.

III. Tři Co je třeba si uvědomit: Nepoužívejte ji špatně

Nechtivě neusilujte o vysoké specifikace: Použijte fotoaparát s rozlišením 20 MP pro detekci rysů o velikosti 0,1 mm; není třeba 50 MP (zvyšuje náklady o 50 %).

Zaměřte se na vhodnost hardwaru: Pro rýhy na kovech použijte šikmé osvětlení, pro průhledné díly zadní osvětlení. Nesprávné osvětlení může zvýšit míru chybných rozhodnutí až o 10 %.

Provádějte pravidelnou údržbu: Čistěte čočky týdně, vyměňujte zdroje světla každý 1–2 roky. Jinak klesá přesnost (např. v jedné továrně stoupla míra chybných rozhodnutí z 0,2 % na 5 % kvůli stárnutí osvětlení).

IV. Shrnutí: Vizuální kontrola je „modernizací systému kontroly kvality“

Nejde pouze o jednoduchou náhradu manuální práce. Spíše rekonstruuje proces kontroly kvality prostřednictvím vysoké přesnosti, vysoké efektivity a digitalizace dat, čímž odpovídá konceptu Průmyslu 4.0 a stává se „klíčovým článkem“ mezi výrobou a kontrolou kvality.