Sumber Cahaya Koaksial Industri: Bidang Aplikasi dan Prinsip Kerja

Sumber cahaya koaksial industri terutamanya digunakan dalam senario industri yang memerlukan penghapusan pantulan permukaan objek, penekanan struktur halus, atau pencapaian pengesanan berketepatan tinggi, dan sangat sesuai untuk pengesanan bahan rata yang mudah memantul cahaya.

Bidang aplikasi utama mereka termasuk:

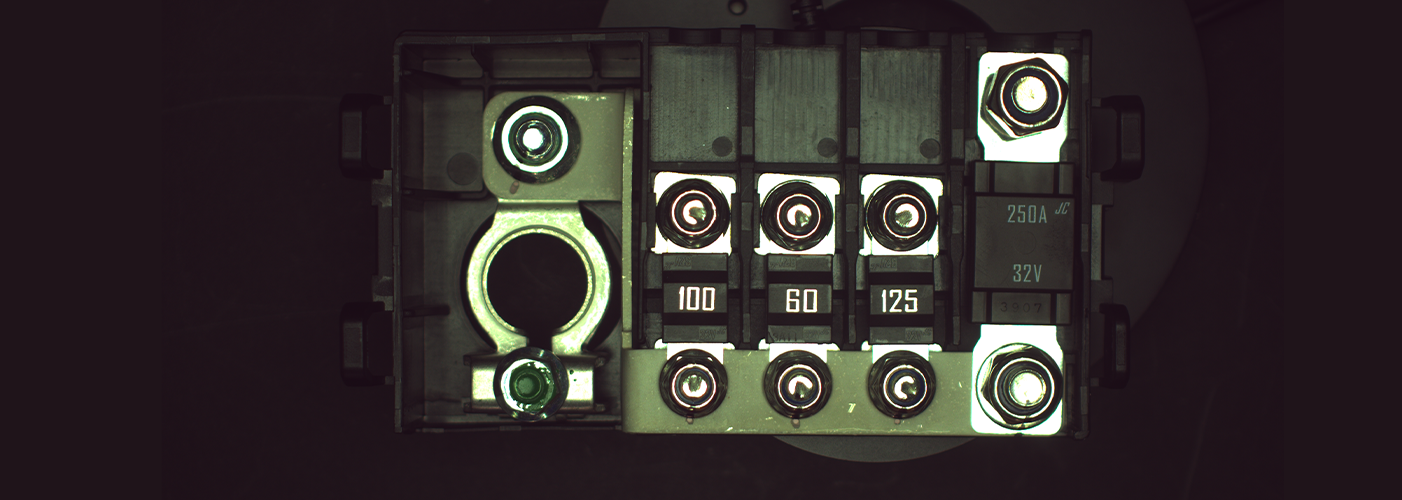

Industri pembuatan elektronik: Pengesanan jejak papan litar PCB, pengesanan keperataan pin cip, dan penentuan kualiti sambungan solder komponen.

Industri Semikonduktor: Pengesanan calar/cacat pada permukaan wafer, pembacaan tanda dan pemeriksaan rupa bentuk semikonduktor selepas pengekalan.

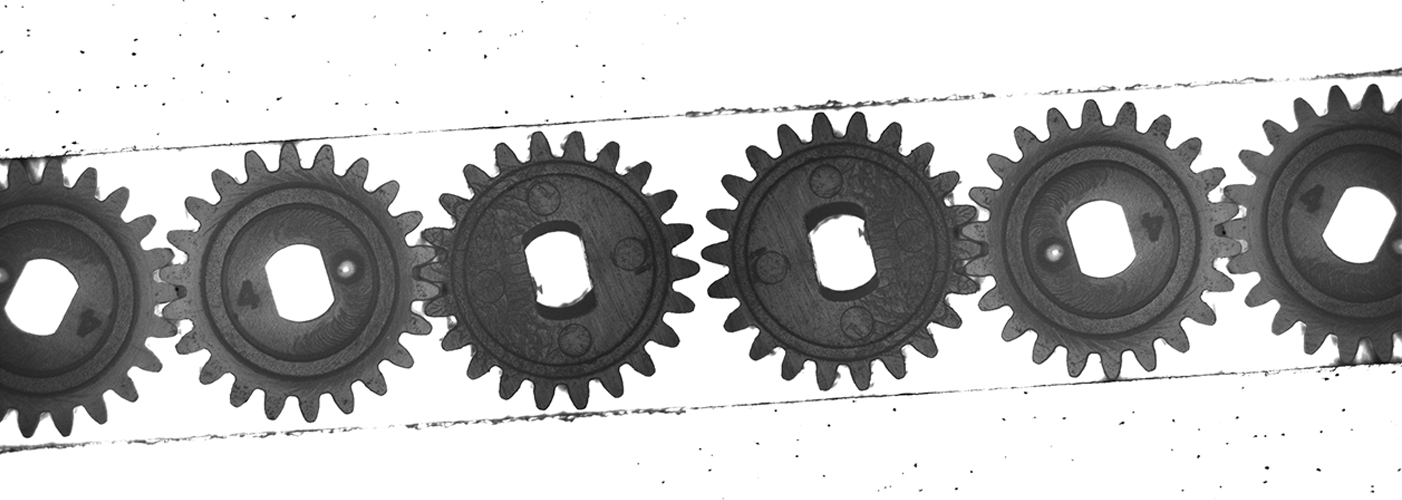

Pengesanan komponen presisi: Pengesanan calar, tompok kotoran, dan pengukuran dimensi pada permukaan bearing logam/kaca, gear, kanta, dll.

Industri paparan LCD/OLED: Pengesanan kecacatan piksel skrin (titik terang/titik gelap), dan pemeriksaan kebersihan permukaan substrat kaca.

Pengesanan komponen automotif: Pengesanan kecacatan permukaan (seperti teritisan, lekuk) dan pengesahan ketepatan pemasangan komponen penempaan presisi automotif serta komponen yang diperah secara suntikan.

Pengesanan barangan pakai perubatan: Pengesanan kecacatan rupa luar dan pengesanan pematuhan dimensi bagi barangan pakai lut-cahaya/lut-sinar seperti picagari dan tiub infus.

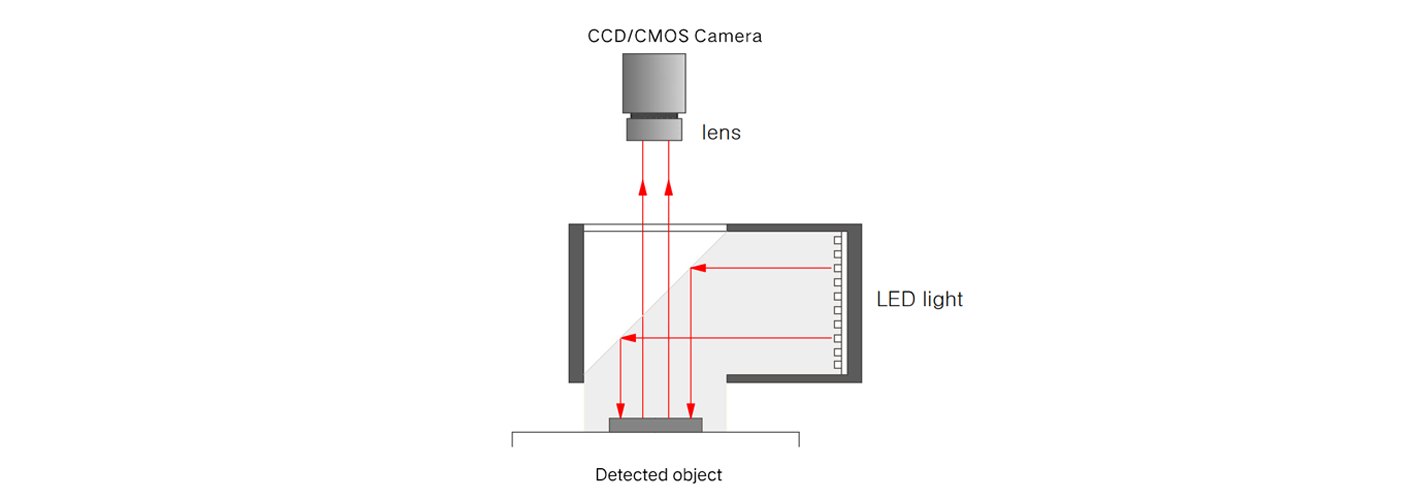

Prinsip kerja utama sumber cahaya koaksial industri adalah menggunakan cermin separa lut-cahaya dan separa pantul (pembahagi alur cahaya) untuk menjadikan sumber cahaya seaksial dengan laluan optik kamera, menghapuskan pantulan permukaan objek yang diukur sambil menerangi secara seragam butiran objek tersebut.

Proses kerja khusus boleh dibahagikan kepada 3 langkah:

Pemancaran cahaya: Cahaya yang dipancarkan oleh manik LED atau sumber cahaya lain mula-mula menyinari secara menegak sebuah cermin separa lutsinar dan separa reflektif yang diletakkan pada sudut 45°.

Pengalihan laluan optik: Cermin separa lut dan separa pantul memantulkan cahaya yang jatuh secara menegak sebanyak 90°, menjadikan arahnya sepenuhnya selari dengan laluan optik pengimejan kamera (iaitu, "koaksial"), dan menyinari permukaan objek yang diukur secara menegak.

Suapan balik imej: Cahaya terpantul dari permukaan objek (tanpa gangguan pantulan, hanya membawa maklumat butiran objek) kembali melalui laluan optik asal, menembusi cermin separa lut dan separa pantul, kemudian memasuki kanta kamera, akhirnya membentuk imej pengesanan yang jelas dengan pantulan rendah.

Kelebihan utama reka bentuk ini ialah ia dapat mengelakkan pantulan kila yang terhasil apabila cahaya menyinar objek yang sangat reflektif (seperti logam dan kaca) pada sudut bukan menegak, membolehkan kamera menangkap dengan lebih tepat butiran seperti calar, kecacatan, dan tekstur pada permukaan objek.