Zasada działania kamery liniowej

Główna zasada działania kamery liniowej polega na wykorzystaniu pojedynczego lub wielu liniowych czujników obrazu w połączeniu z jednostajnym ruchem obiektu fotografowanego (lub samej kamery), aby zbierać dane obrazowe wiersz po wierszu, a następnie zszywać je w kompletny obraz 2D.

Jej kluczowe kroki pracy są następujące:

Pomiar światła liniowego: Głównym komponentem jest liniowy czujnik obrazu (taki jak CCD lub CMOS), który może przechwytywać wyłącznie jednowymiarową informację pikselową w kierunku „linii” (poziomym), w przeciwieństwie do dwuwymiarowej informacji z kamery powierzchniowej.

Synchronizacja jednostajnego ruchu: Należy zapewnić stabilny ruch jednostajny względny między kamerą a fotografowanym obiektem (np. obiekt porusza się taśmociągiem, kamera przesuwa się wzdłuż szyny prowadzącej). Kierunek ten jest kierunkiem "wiersza" (pionowym) obrazu.

Przechwytywanie i łączenie po wierszach: Czujnik rejestruje jednowymiarowe dane pikseli wiersz po wierszu z określoną częstotliwością (częstotliwość linii), a każdy wiersz danych odpowiada nowej pozycji obiektu po przemieszczeniu; wewnętrzny system kamery lub system zaplecza łączy te ciągłe "obrazy liniowe" sekwencyjnie, tworząc ostatecznie kompletny obraz 2D.

Ta zasada determinuje, że kamery liniowe są bardziej odpowiednie do inspekcji szybko poruszających się, długich lub dużych obiektów (takich jak wydruki, płyty metalowe, tkaniny itp.) i zależą od zewnętrznych mechanizmów ruchu zapewniających jakość obrazowania.

A zastosowania kamer liniowych

Główne scenariusze zastosowania kamer liniowych koncentrują się na wysokoprecyzyjnym obrazowaniu i inspekcji obiektów o dużej prędkości, dużym obszarze i dużej długości, a są szczególnie odpowiednie dla scenariuszy wymagających ciągłego dynamicznego pozyskiwania danych. Typowe dziedziny to:

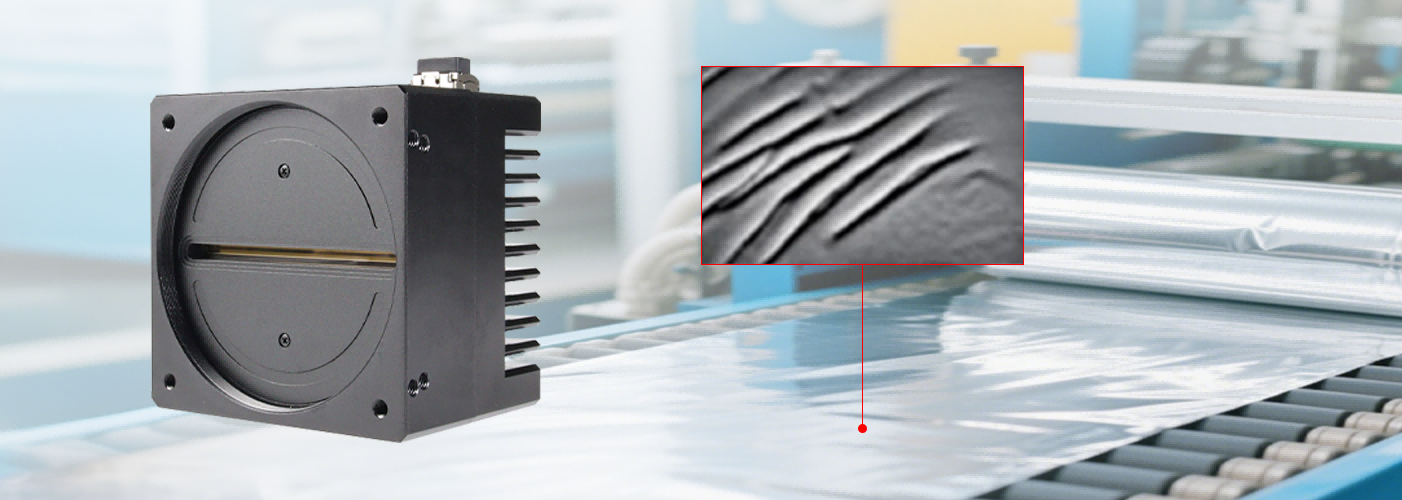

Dziedzina kontroli przemysłowej: Jest to najbardziej podstawowy scenariusz zastosowania kamer liniowych. Są one używane do kontroli ciągle poruszających się materiałów na liniach produkcyjnych, takich jak płyty/zwoje metalowe (kontrola wad powierzchni), szkło/folie (kontrola płaskości i zanieczyszczeń), wyroby drukowane (kontrola dokładności nakładania kolorów i wad tekstu) oraz elektrody do baterii litowych (kontrola jednorodności powłoki).

Dziedzina logistyki i pakowania: Są one używane do pomiaru objętości paczek i identyfikacji kodów kreskowych/kodów QR na szybkich liniach sortujących, a także do kontroli integralności wyglądu ciągle pakowanych produktów (takich jak żywność w workach czy tekturowe kartony).

Dziedzina druku i przemysłu tekstylnego: W maszynach do drukowania webowego i liniach produkcyjnych do farbowania/druku tkanin wykonują one rzeczywistą kontrolę różnic kolorów w nadrukach oraz wad faktury tkaniny (takich jak przerwane nici czy dziury), aby zapewnić jakość produkcji.

Dziedzina transportu i bezpieczeństwa: Są wykorzystywane do skanowania konturu pojazdów na bramkach autostradowych (w celu uzyskania danych modelu i rozmiaru pojazdu) lub do inspekcji torów kolejowych (w celu wykrywania zagrożeń, takich jak pęknięcia czy zużycie powierzchni toru).

Dziedzina medycyny i badań naukowych: Częściowo stosowane są w obrazowaniu medycznym (np. w wysokorozdzielczej analizie przekrojów patologicznych), obserwacji próbek biologicznych lub liniowym skanowaniu obrazów przemysłowych CT — sytuacjach wymagających wysokiej precyzji i rozdzielczości.