Объективы для машинного зрения: особенности глубины резкости при различном размере объектов контроля

Объективы для машинного зрения: оптимизация глубины резкости для различных промышленных проверок

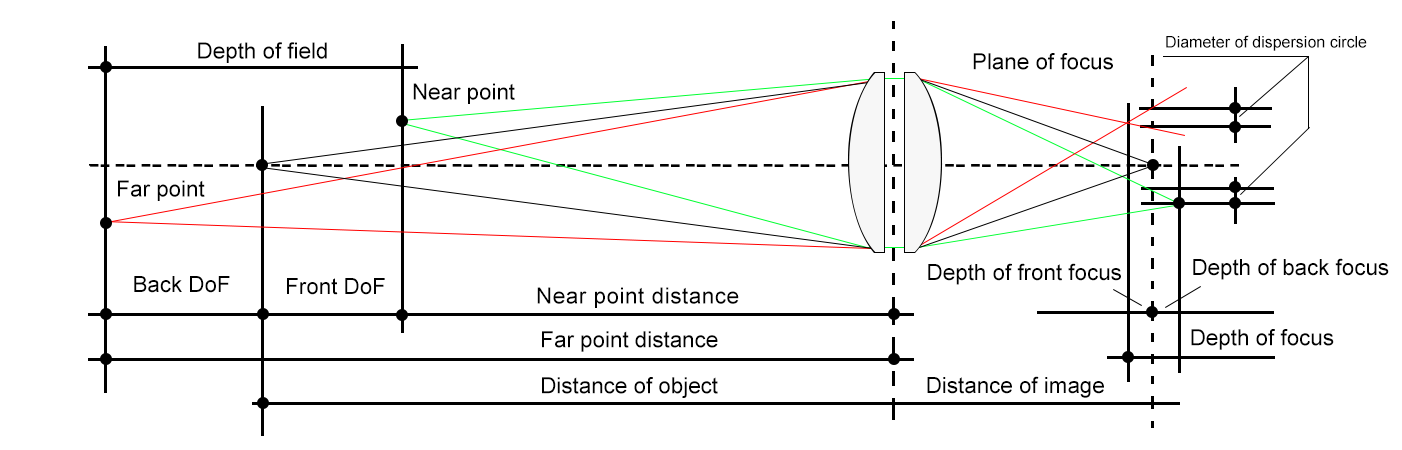

Введение: Критическая роль глубины резкости в точном контроле В системах машинного зрения, глубина резкости (DoF) определяет диапазон допустимой четкости для объектов контроля. Поскольку промышленные процессы обрабатывают компоненты от субмиллиметровой электроники до многометровых промышленных сборок, овладение DoF становится решающим фактором в точности и эффективности. Для принятия решений на B2B-уровне согласование возможностей объектива с изменчивостью размера объекта может определить частоту упущенных дефектов, простои производства и общие эксплуатационные затраты.

Проблема глубины резкости: Размер объекта диктует оптическую стратегию

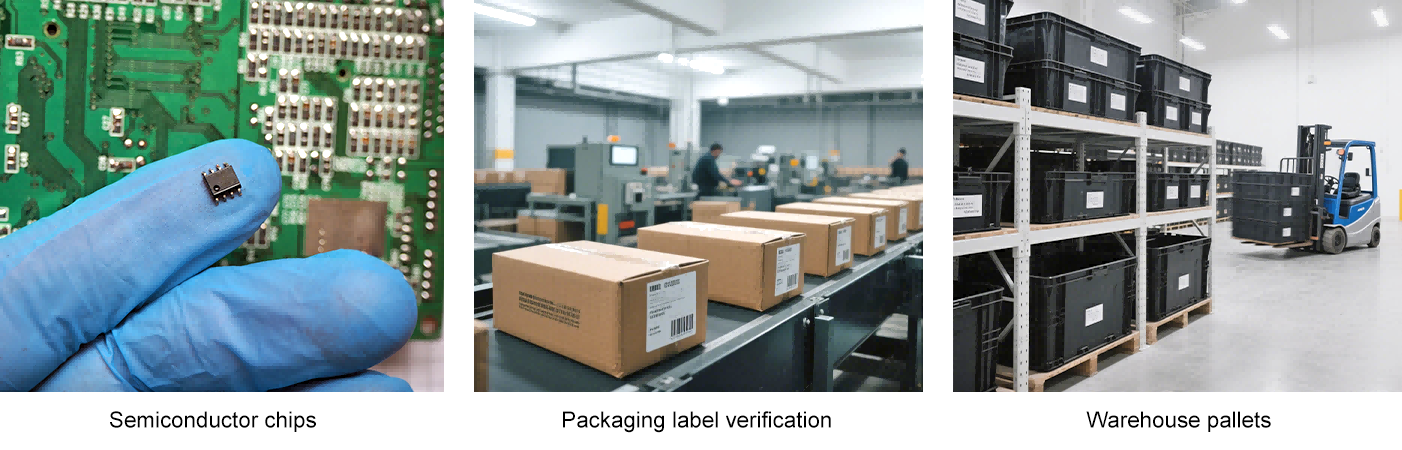

Микроскопические объекты: Когда каждый микрон имеет значение Проверка компонентов, таких как полупроводниковые чипы или медицинские имплантаты, требует экстремального увеличения. Однако высокое увеличение значительно сужает ГБ (глубину резкости). Незначительные изменения высоты — вызванные вибрацией конвейера или деформацией детали — могут сделать критические дефекты (например, трещины в пайке или микроскопические царапины) невидимыми. Традиционные объективы могут испытывать трудности в такой ситуации, потенциально увеличивая ложноположительные результаты на 10–15% в высокоскоростных линиях SMT.

Компоненты средних размеров: гибкость против стабильности При проверке ПЛС или подтверждении этикеток упаковки объекты часто имеют изогнутые поверхности или позиционные несоответствия. Объектив должен находить баланс между разрешением деталей и терпимостью к отклонениям высоты ±2–5 мм. Если ГБ слишком мала, предприятия могут столкнуться с повторной калибровкой, что может замедлить производительность до 20% в автоматизированных упаковочных линиях.

Большие/3D-структуры: противостояние физическим ограничениям Панели кузова автомобиля или складские паллеты требуют широкого охвата ГП (50–100 мм и более) по неровным плоскостям. Стандартные объективы редко достигают этого в одном кадре. Одна автомобильная компания сообщила о на 70% более высоких ручных затратах на переделку из-за неучтенных дефектов кромок на криволинейных поверхностях — прямого следствия недостаточной глубины резкости.

Настроенные оптические решения для промышленной масштабируемой изменчивости

Точная фокусировка для микрообъектов Телецентрические объективы часто являются незаменимыми здесь. Их параллельные световые пути устраняют перспективную искаженность, предлагая сравнительно большую ГП при высоком увеличении. Ключевые применения включают:

- Оптимизация диафрагмы : Закрытие диафрагмы (более высокий f/#) увеличивает ГП, но требует интенсивного, коаксиального освещения для поддержания экспозиции.

- Протоколы стабильности : Точные крепления и противовибрационные стадии компенсируют колебания на уровне микрометров. Например, для телецентрической серии HIFLY пользователи могли достичь постоянной глубины резкости (DoF) ±0,05 мм при проверке датчиков MEMS, сократив ложные отбраковки на 40%.

Адаптивная оптика для средних объектов Промышленные объективы с фиксированным фокусом и регулируемыми диафрагмами предлагают универсальный компромисс. Ключевые моменты включают:

- Балансировка параметров : Увеличение рабочего расстояния (WD) или уменьшение фокусного расстояния увеличивает глубину резкости (DoF), но может снижать разрешение.

- Динамический контроль диафрагмы : Некоторые системы интегрируют реальное время корректировки f/# через программное обеспечение, когда датчики высоты обнаруживают отклонения объекта. Один логистический интегратор использовал этот подход, чтобы поддерживать 99,2% точности считывания неравномерно сложенных посылок, сократив простои системы на 35%.

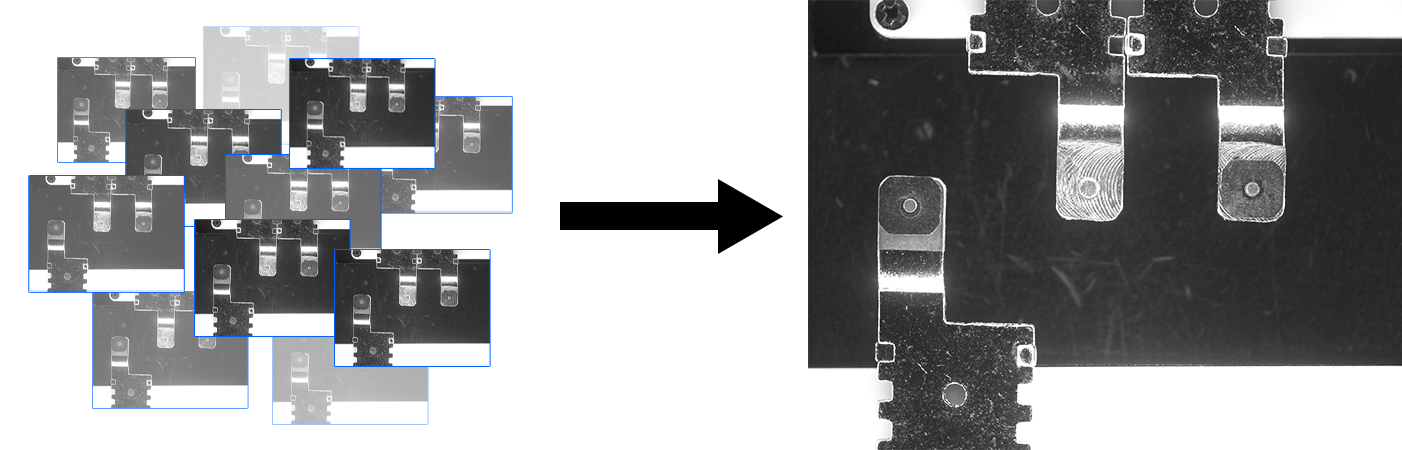

Продвинутые методы для большого масштаба глубины Когда физические ограничения по степеням свободы недостаточны, многофреймовая фьюзия закрывает этот пробел:

- Слоевая фокусировка : Быстро захватывает 10–30 изображений на разных фокальных плоскостях, затем объединяет резкие области в одно составное изображение. Современные промышленные системы выполняют это менее чем за 1 секунду на точку контроля.

- Оптика с кодированием волнового фронта : Специализированные линзы используют манипуляцию фазой для оптического расширения глубины резкости, хотя требуется вычислительная постобработка. Эти методы могут сократить потребность в развертывании камер на 50% при осмотре крупных деталей, как подтверждено в рабочих процессах обеспечения качества металлообработки.

Стратегическая реализация: Соотнесение оптики с деловыми результатами

Шаг 1: Сопоставьте требования к осмотру с оптическими расчетами Используйте базовую формулу ГР:

ГР ≈ 2 × Размер пикселя × (РД)² × f/# / (Фокусное расстояние)²

Приоритет:

- Размер пикселя и РД для крупных объектов.

- f/# и фокусное расстояние для микроэлементов.

Шаг 2: Проверка совместимости освещения Оптимизация степеней свободы зависит от освещения. Например:

- Микроконтроль с малым отверстием требует коаксиальных массивов LED с интенсивностью 100,000+ люкс.

- Слоистая фокусировка требует равномерного освещения без теней на всех фокальных плоскостях.

Шаг 3: Расчет общей стоимости владения (TCO) Учитывайте:

- Снижение затрат на переделку (например, 30%-ное сокращение дефектов покраски в автомобилестроении).

- Повышение производительности за счет уменьшения перекалибровки фокуса.

- Экономия на гибкости при изменении ассортимента продукции.

Шаг 4: Обеспечьте перспективу будущего развития с масштабируемыми архитектурами Выберите модульные системы, поддерживающие:

- Возможность замены объектива (например, от телецентрических до макрообъективов).

- Обновляемую через программное обеспечение фокусную стеку.

- Контроллеры освещения, синхронизированные с корректировками диафрагмы.

Вывод: Глубина резкости как множитель эффективности

В промышленной автоматизации ГР не является просто оптической физикой — это стратегическая переменная, влияющая на выход, скорость и стоимость. Предприятия, проверяющие компоненты разных масштабов, могут достичь измеримых улучшений путем:

- Соответствия типов объектива экстремальным размерам объектов (телецентрический для микроскопических, фокусная стека для макроскопических).

- Автоматизации настройки параметров с помощью обратных связей систем машинного зрения.

- Предварительная интеграция оптики и освещения для предотвращения проблем совместимости.